Our Induction Heating Products

High-performance, durable, and energy-efficient induction heating equipment designed for industrial applications.

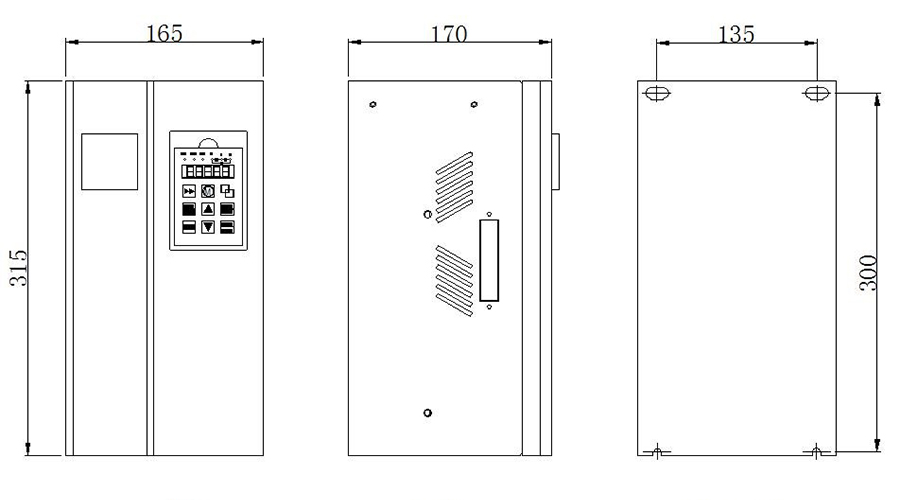

Induction Heating Power Supplies

High-frequency power units designed for stable and efficient induction heating performance across various industrial applications.

- • Frequency range: 1-100 kHz

- • Power output: 5kW to 500kW

- • IGBT-based inverter technology

- • Digital temperature control

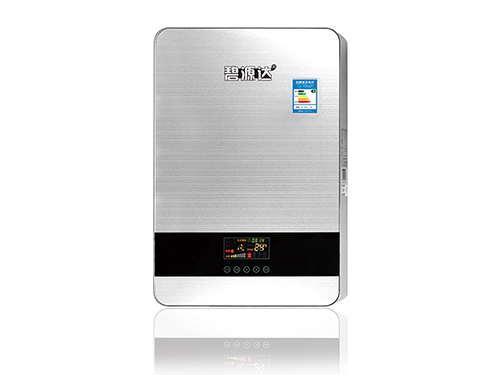

Induction Central Heating Boiler

Eco-friendly central heating solution using electromagnetic induction for clean, efficient, and quiet operation.

- • Thermal efficiency up to 98%

- • No combustion, zero emissions

- • Compact modular design

- • Suitable for commercial buildings

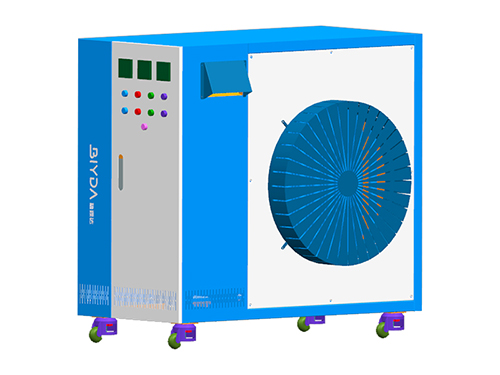

Induction Heating Hot Air Generator

Delivers high-temperature air rapidly for drying, curing, and industrial processing applications.

- • Output temp: up to 600°C

- • Airflow control system

- • Fast heat-up time

- • Corrosion-resistant materials

High-Frequency Induction Power Supply

Advanced high-frequency units ideal for precision heating in small-scale industrial processes.

- • Frequency: 10-100 kHz

- • Power: 3kW to 100kW

- • PWM control system

- • Overload and overheat protection

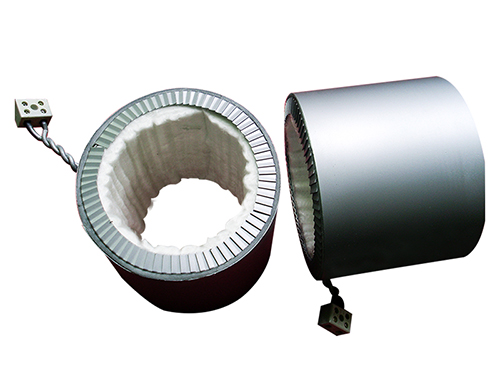

Custom Induction Coils

Precision-engineered copper coils tailored to specific application geometries and heating requirements.

- • High-purity oxygen-free copper

- • Water-cooled design

- • Custom shapes and sizes

- • Long service life

Medium Frequency Induction Heater

Optimized for deep penetration heating in large metal components and industrial forging.

- • Frequency: 1-10 kHz

- • Power: 50kW to 1000kW

- • Robust industrial enclosure

- • PLC integration capability

Induction Heating Steam Generator

Instant steam generation using electromagnetic induction for industrial sterilization, cleaning, and processing.

- • Steam output: 50–500 kg/h

- • Instant start-up

- • No scale buildup

- • Fully automated operation

Industrial Heating Solutions

Complete turnkey systems for plastic processing, chemical reactors, piping, and drying equipment.

- • Custom system design

- • On-site installation support

- • Energy audit & optimization

- • Remote monitoring available