About Zhengzhou Sunrise Refractory

Zhengzhou Sunrise Refractory Co., Ltd. is located in central China, strategically positioned near the major railway intersection of Jingguang and Longhai, and close to Zhengzhou Xinzheng International Airport. This prime location enables efficient logistics and global distribution.

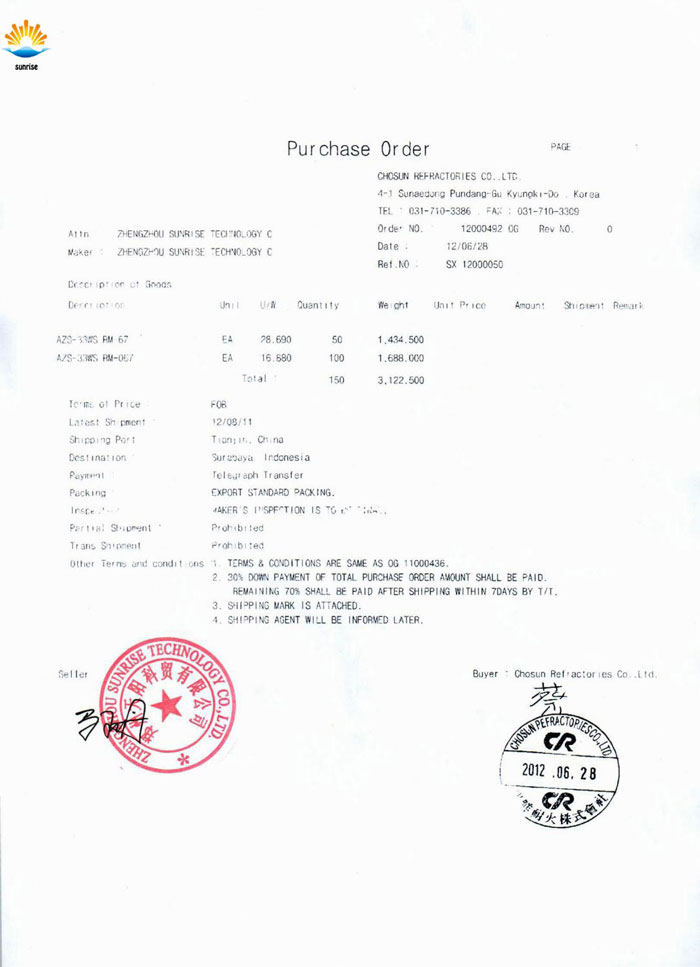

We specialize in manufacturing high-quality refractory insulation products used in blast furnaces, glass furnaces, ceramic kilns, hot air stoves, and other high-temperature industrial applications. Our commitment to innovation and quality has allowed us to build long-term partnerships with clients across the globe.

With decades of experience, we continue to expand our export business, delivering reliable, cost-effective thermal insulation solutions that meet international standards.