Precision Insulating Glass Machinery

Automated IGU production lines trusted by over 1,000 manufacturers worldwide. 30+ years of engineering excellence delivering high-speed, low-maintenance solutions.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Automated IGU production lines trusted by over 1,000 manufacturers worldwide. 30+ years of engineering excellence delivering high-speed, low-maintenance solutions.

LIJIANG GLASS specializes in the R&D and manufacturing of automatic insulating glass machinery with a registered capital of 20 million RMB. With nearly one thousand domestic and international customers — including North Glass, Xinfuxing, and Yaohua — our equipment has been exported to Europe, the United States, the Middle East, Southeast Asia, South America, and beyond.

Our mission is to deliver precision-engineered, reliable, and scalable solutions that enhance productivity and quality in double and triple glazing production.

From washing to sealing, filling to handling — we offer a complete suite of automated machinery for insulating glass unit (IGU) manufacturing.

Fully automated vertical system for high-volume double glazing production.

View Details

Precision robotic sealing with consistent bead control and minimal waste.

View Details

High-speed aluminum spacer forming with digital length control.

View Details

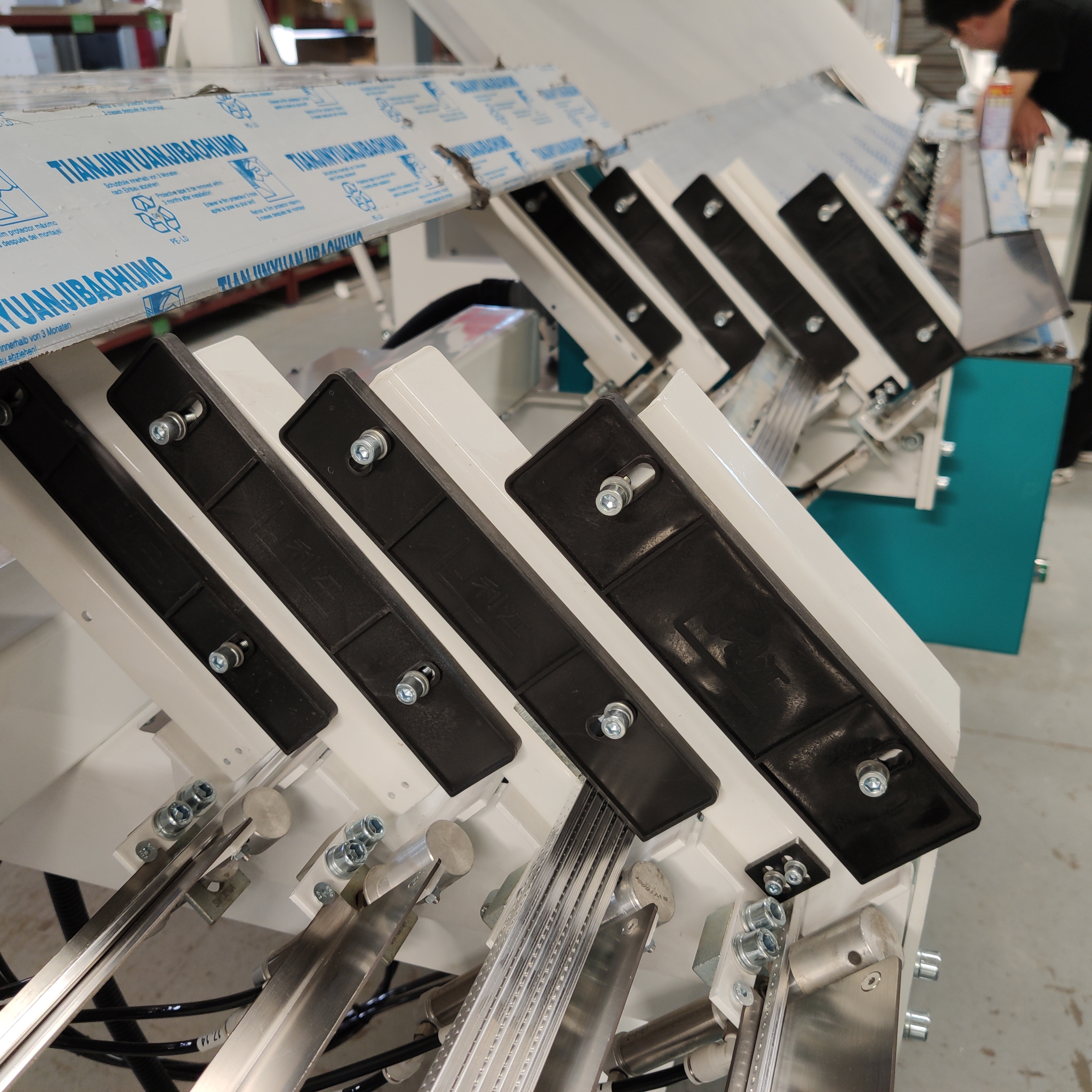

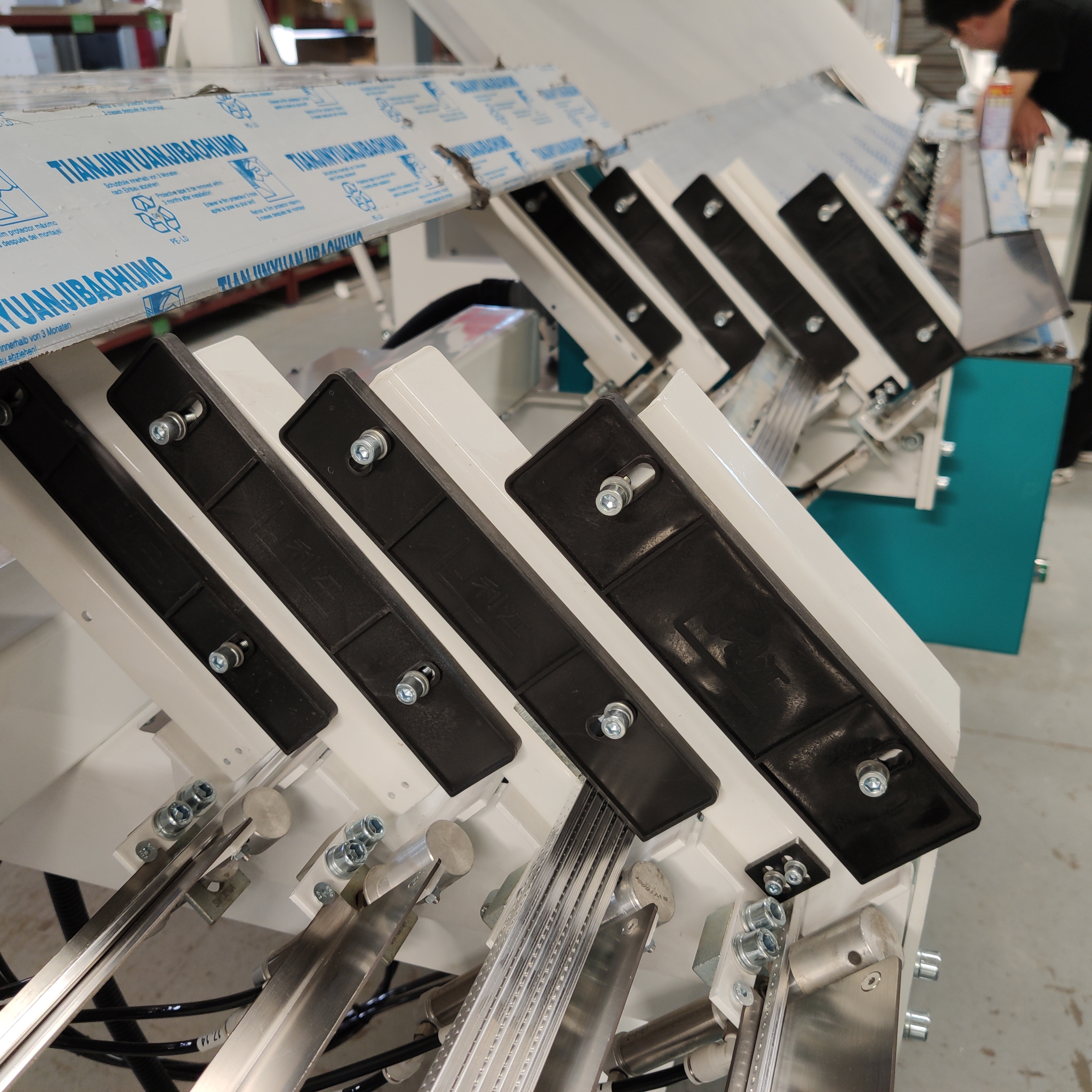

Dual-head butyl application for fast, uniform primary seal coating.

View Details

High-accuracy molecular sieve filling with big barrel option.

View Details

Heavy-duty lifting system for safe glass handling in production.

View Details

High-speed aluminum spacer cutting with automatic length setting.

View DetailsEngineered for performance, reliability, and long-term value.

CNC-machined components and advanced control systems ensure repeatable accuracy.

Optimized workflows deliver up to 1,200 units per shift depending on configuration.

Durable construction and modular design reduce downtime and service costs.

Installation, training, and remote diagnostics available worldwide.

We offer vertical, horizontal, and jumbo-size automatic insulating glass production lines, including models with argon gas filling and robotic sealing.

Yes, all washing and handling systems use Low-E safe brushes and components to prevent coating damage.

Yes, we offer on-site installation, operator training, and remote support to ensure smooth startup.

Depending on configuration, our lines can produce between 600 and 1,200 IGUs per 8-hour shift.

Yes, we offer customized configurations to match your space, workflow, and production goals.

For product inquiries, technical support, or custom solutions — visit our official website to contact the team.

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info