Who We Are

Trusted Precision Manufacturer for Global OEMs

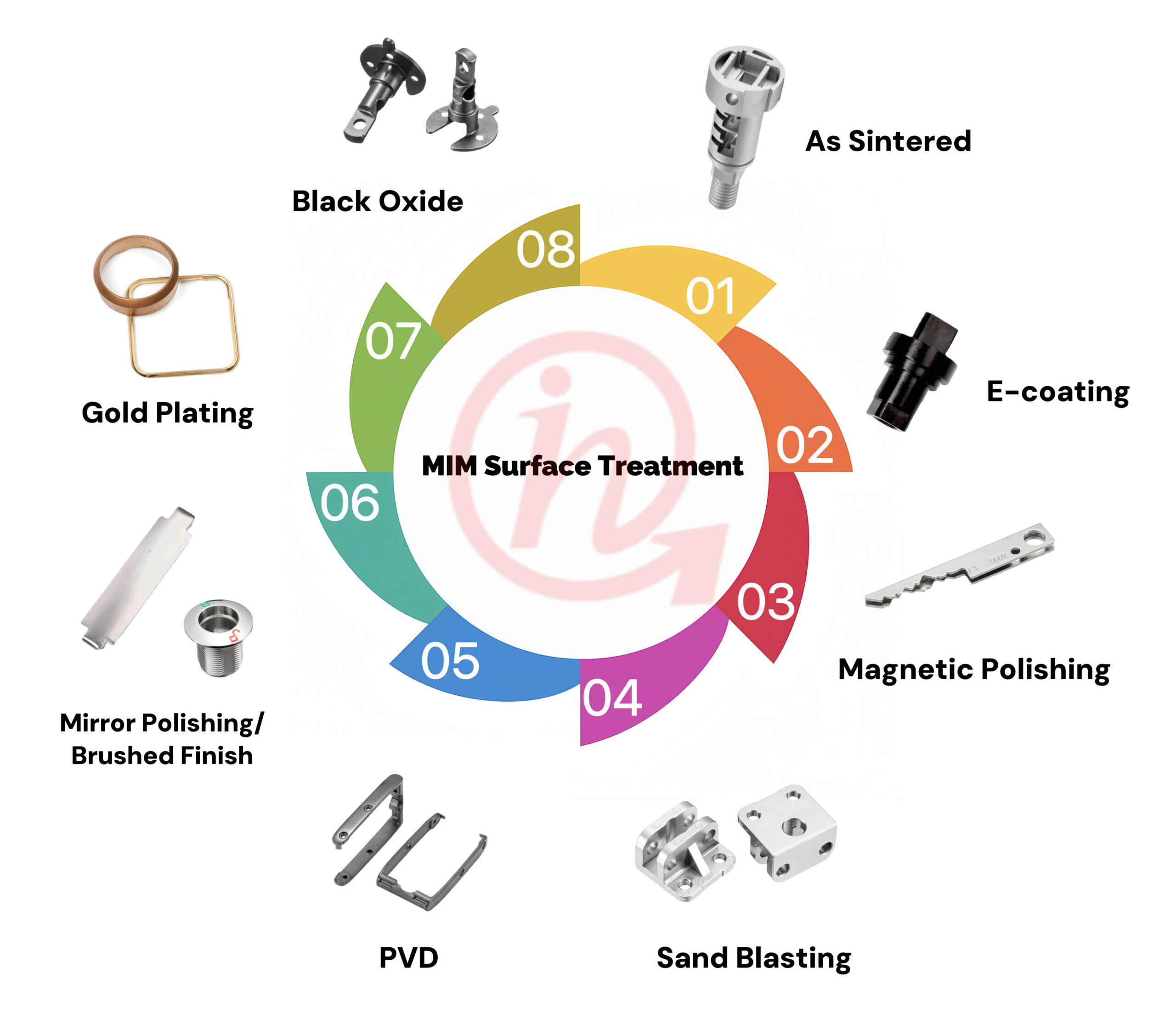

ISDN Precision is part of ISDN Holdings, a listed engineering group in Singapore. We specialize in certified Metal Injection Molding (MIM) manufacturing, producing high-precision metal parts for the automotive, medical, electronics, and security industries.

Our factory in Huzhou, Zhejiang, China is ISO certified and fully equipped for mass production — from tooling and injection molding to debinding, sintering, post-processing, and final inspection.

Learn More