About Shenzhen Jamit Technology

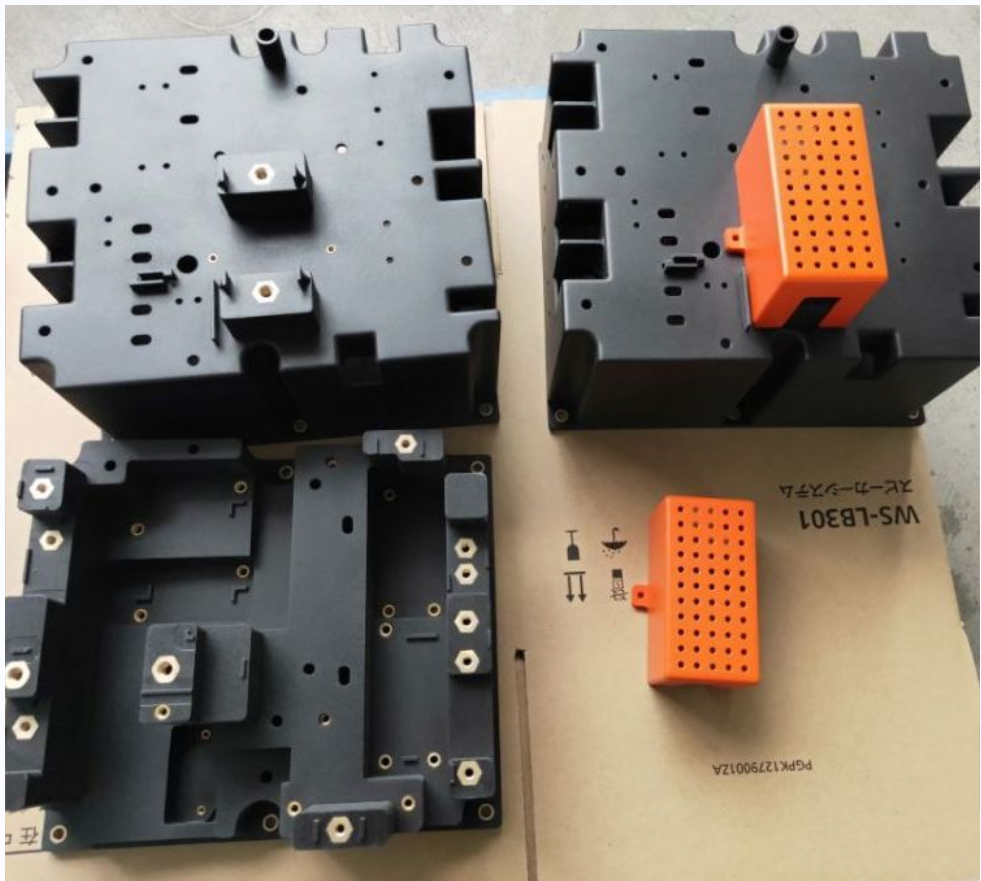

Shenzhen Jamit Technology Co., Ltd is a professional manufacturer providing one-stop service including design, development, prototyping, mold making, injection molding, surface treatment, and assembly.

With over 11 years of experience, our factories are located in Shenzhen and Huizhou, Guangdong Province, China. We specialize in transforming your concept into a high-quality, fully functional product — from idea to mass production.

11+

Years of Industry Excellence