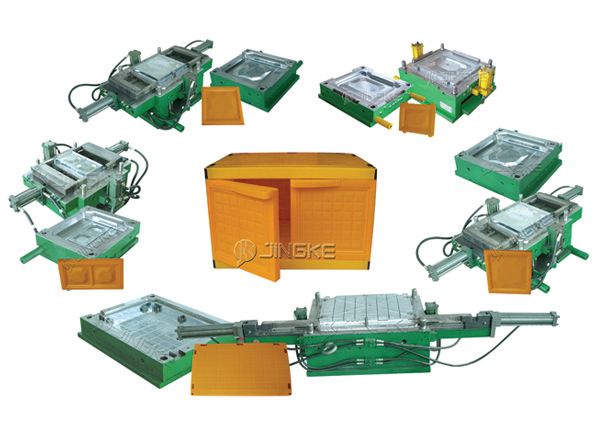

About JingKe Mould

A legacy of precision, innovation, and quality in plastic mold manufacturing since the 1980s.

Company Overview

JingKe Mould Enterprise is located in Huangyan District, Taizhou City, Zhejiang Province — one of China’s most renowned hubs for mold manufacturing. With over forty years of experience, we have built a strong reputation for delivering high-precision injection molds to clients across the globe.

Our team combines traditional craftsmanship with modern engineering to produce molds that meet the highest international standards. We are proud to hold ISO9001:2000 international quality certification, reflecting our commitment to consistent excellence in every project.

Established

40+ Years

of experience in plastic mold production

Certified Quality

ISO9001:2000

International quality management standard

Global Reach

Worldwide

Clients across Europe, Asia, and the Americas