Welcome to Jinsun Carbon

We manufacture high-quality graphite electrodes and carbon products for EAF steelmaking, refining, and industrial smelting applications. With over 15 years of experience, we deliver reliable, high-performance materials trusted globally.

Your Reliable Partner in Industrial Materials

As a dedicated graphite electrode manufacturer in China, JINSUN develops premium carbon and graphite products for electric arc furnaces, refining furnaces, and submerged arc furnaces. Our UHP, HP, and RP graphite electrodes are engineered for extreme temperatures up to 1600 °C.

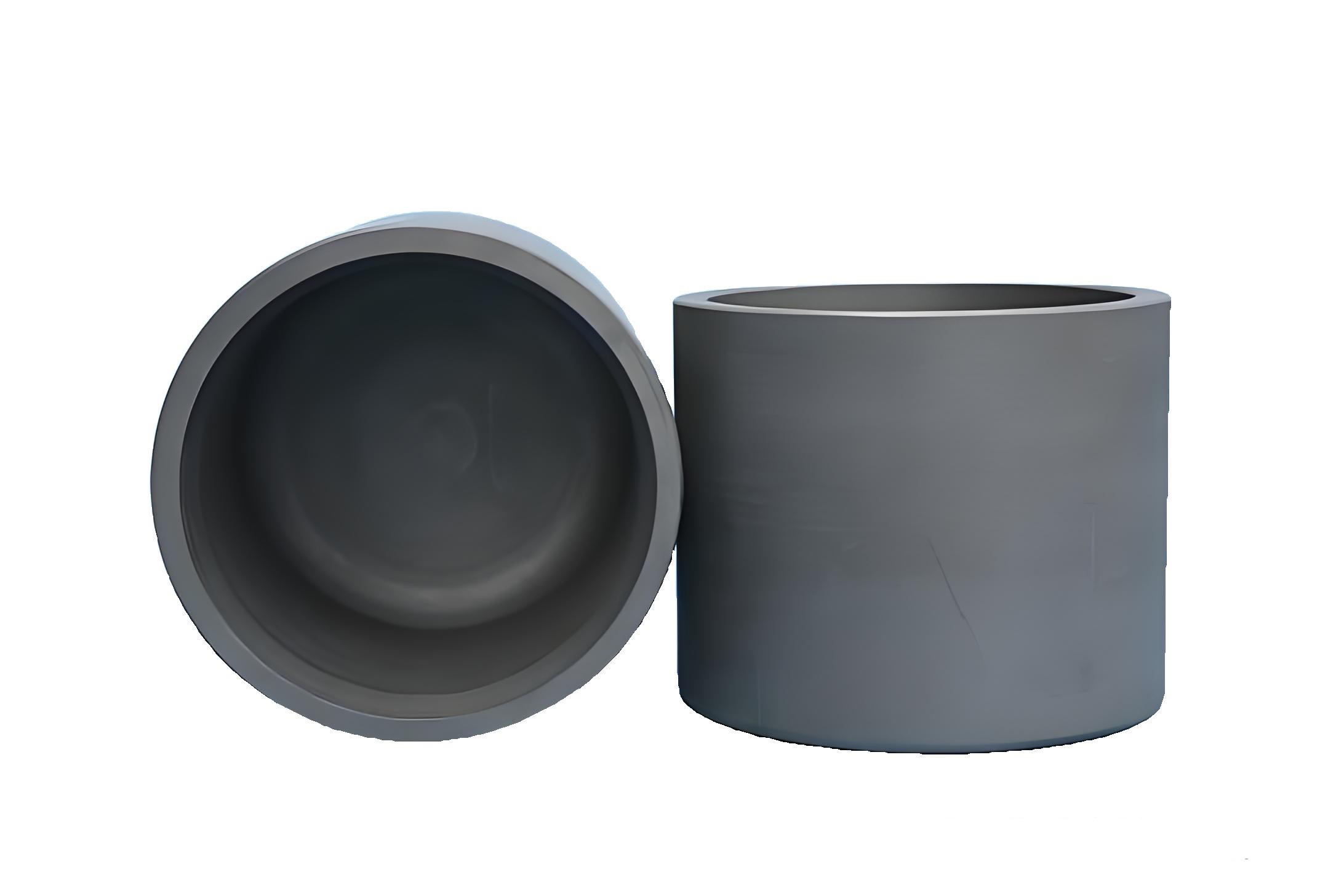

We also supply cathode blocks for aluminum electrolysis, carbon electrodes, electrode paste for ferroalloy furnaces, and a full range of graphite products including crucibles, rods, blocks, and furnace linings.

Learn More About Our Technology →