About JX Abrasives

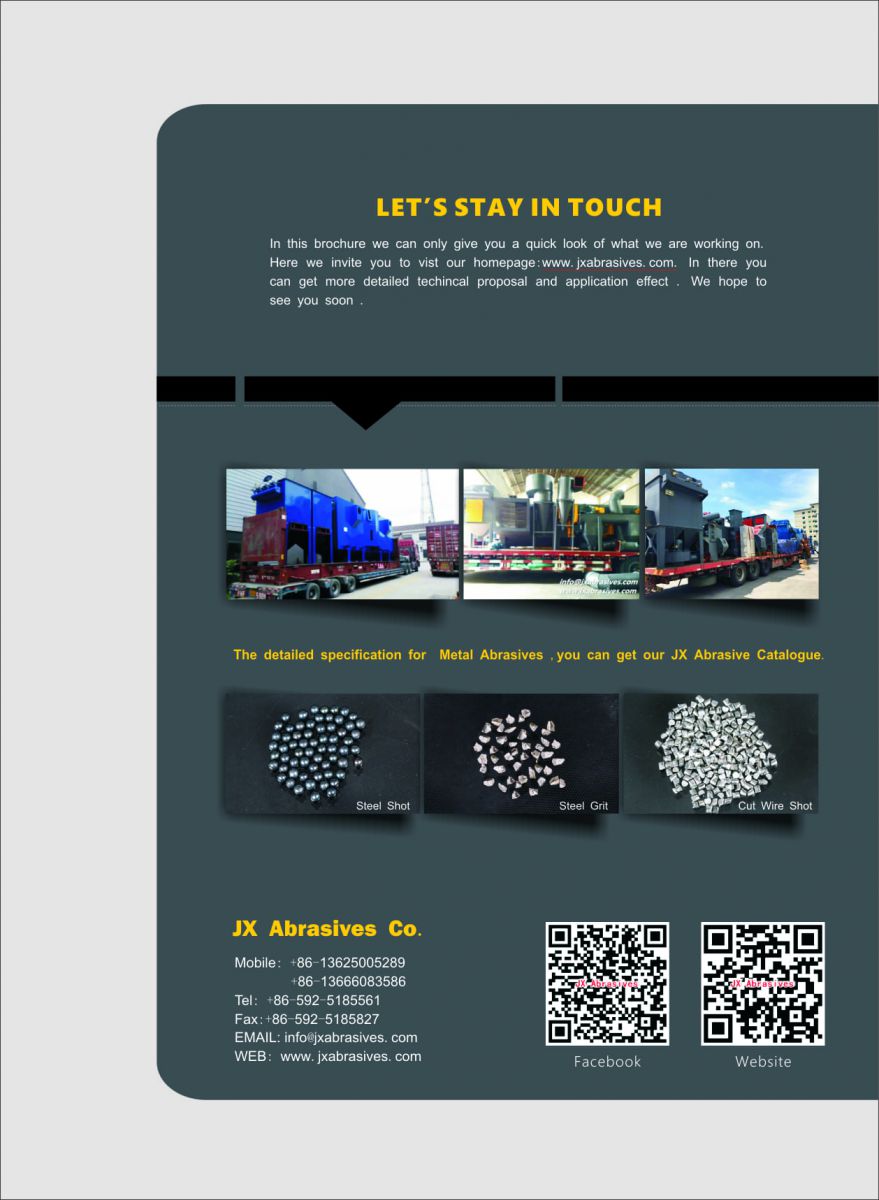

With over 20 years of experience, JX Blasting is a professional manufacturer of shot blasting and shot peening machines. We specialize in providing comprehensive surface preparation solutions for industries including aerospace, automotive, shipbuilding, railway, forging, foundry, and steel structures.

As a leading surface preparation company in China, we are committed to reducing production costs through affordable equipment, expert technical guidance, and longer-lasting abrasives. Our goal is to simplify your surface preparation needs and elevate your business to new heights.

- 20+ Years of Industry Experience

- ISO-Certified Manufacturing

- Global Installation in 50+ Countries

- Dedicated Technical Support Team