Our Products

High-performance robotic systems for industrial automation and injection molding

Five Axis Servo Robot

Enhanced functionality with multi-angle jig positioning. Ideal for complex part handling in injection molding.

- 5-axis motion control

- High precision servo motors

- Injection molding optimized

Six Axis Servo Robot

Full rotational freedom with six servo motors for maximum flexibility in part handling and assembly.

- 6-axis articulated movement

- 360° rotation capability

- Advanced motion programming

Three Axis Servo Robot

Dedicated automation for injection molding production. Reduces manual labor and improves consistency.

- X, Y, Z axis control

- Fast cycle times

- Easy integration

CNC Lathe Robot

Automated loading/unloading system for CNC lathes, increasing uptime and reducing labor costs.

- CNC integration ready

- High repeatability

- Compact design

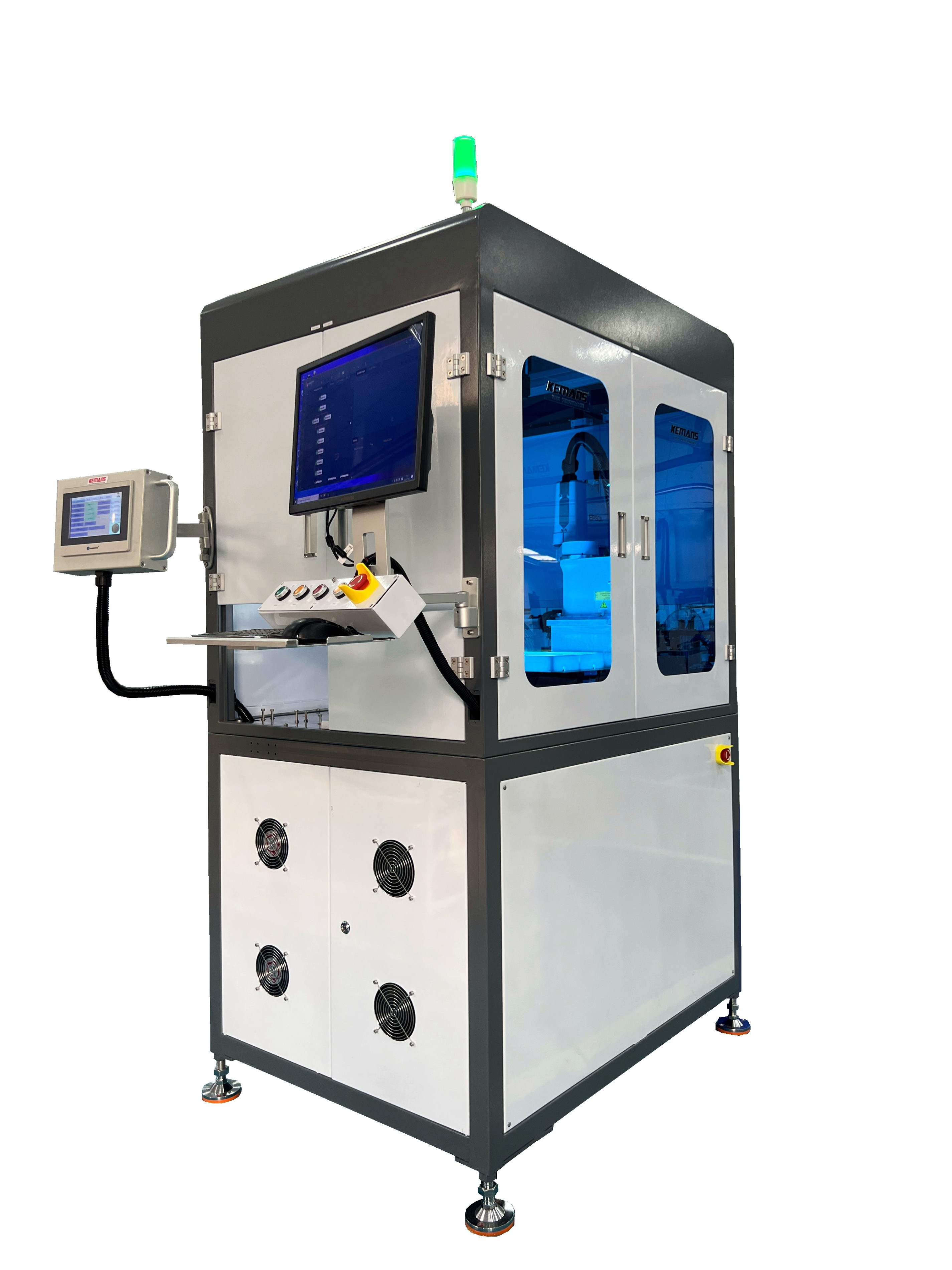

Automatic Packing Machine

Fully automated system for shaping, arranging, and packing products efficiently.

- Auto-shaping & arrangement

- High-speed operation

- Minimal supervision needed

Twin Belt Conveyors

Transfer products or half-products between process units with precision and reliability.

- Friction drive system

- Smooth product transfer

- Modular design

Sprue Cut System

Automated removal and separation of sprue from molded parts for clean post-processing.

- Precision cutting

- Integrated with robots

- Minimizes waste

Pallet Changer & Stacker

Automated handling and stacking of pallets for efficient material logistics.

- High load capacity

- Fast cycle operation

- Safe handling system