Premium Shaker Screens for Oil & Gas Drilling

High-performance replacement screens for Derrick, SWACO, Brandt, KEMTRON, SCOMI, FSI & Vortex shale shakers. Engineered for durability, efficiency, and API RP 13C compliance.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

High-performance replacement screens for Derrick, SWACO, Brandt, KEMTRON, SCOMI, FSI & Vortex shale shakers. Engineered for durability, efficiency, and API RP 13C compliance.

ANPING KANGERTONG HARDWARE & MESH CO., LTD – Your Trusted Partner in Oilfield Shaker Screen Manufacturing

Located in Anping County, Hebei Province, China – known as "the hometown of wire mesh all over the world."

Founded in 2007, we’ve spent over 15 years innovating and perfecting our shaker screen manufacturing processes.

Our products are trusted across the Middle East, Europe, Americas, Southeast Asia, and beyond.

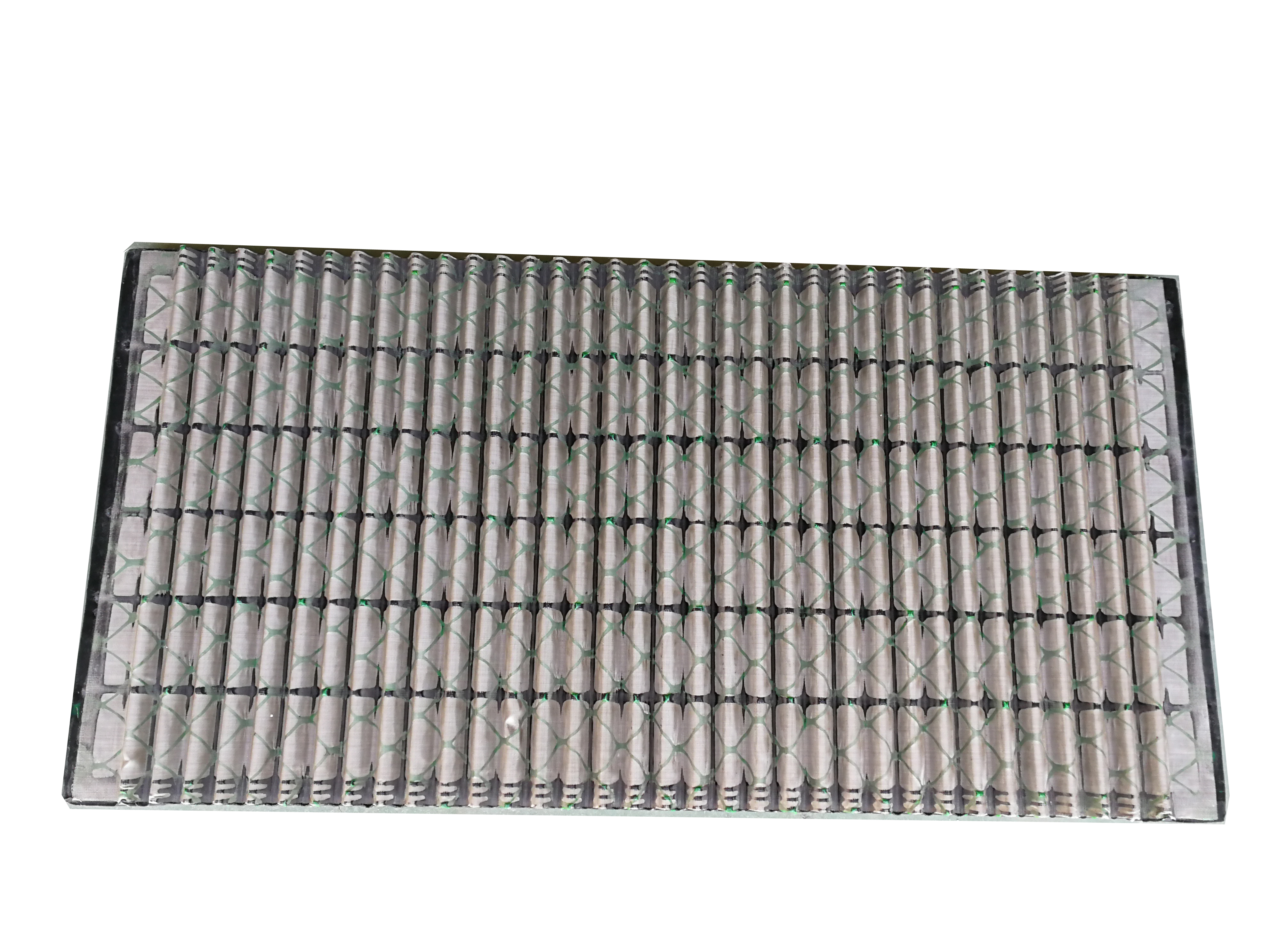

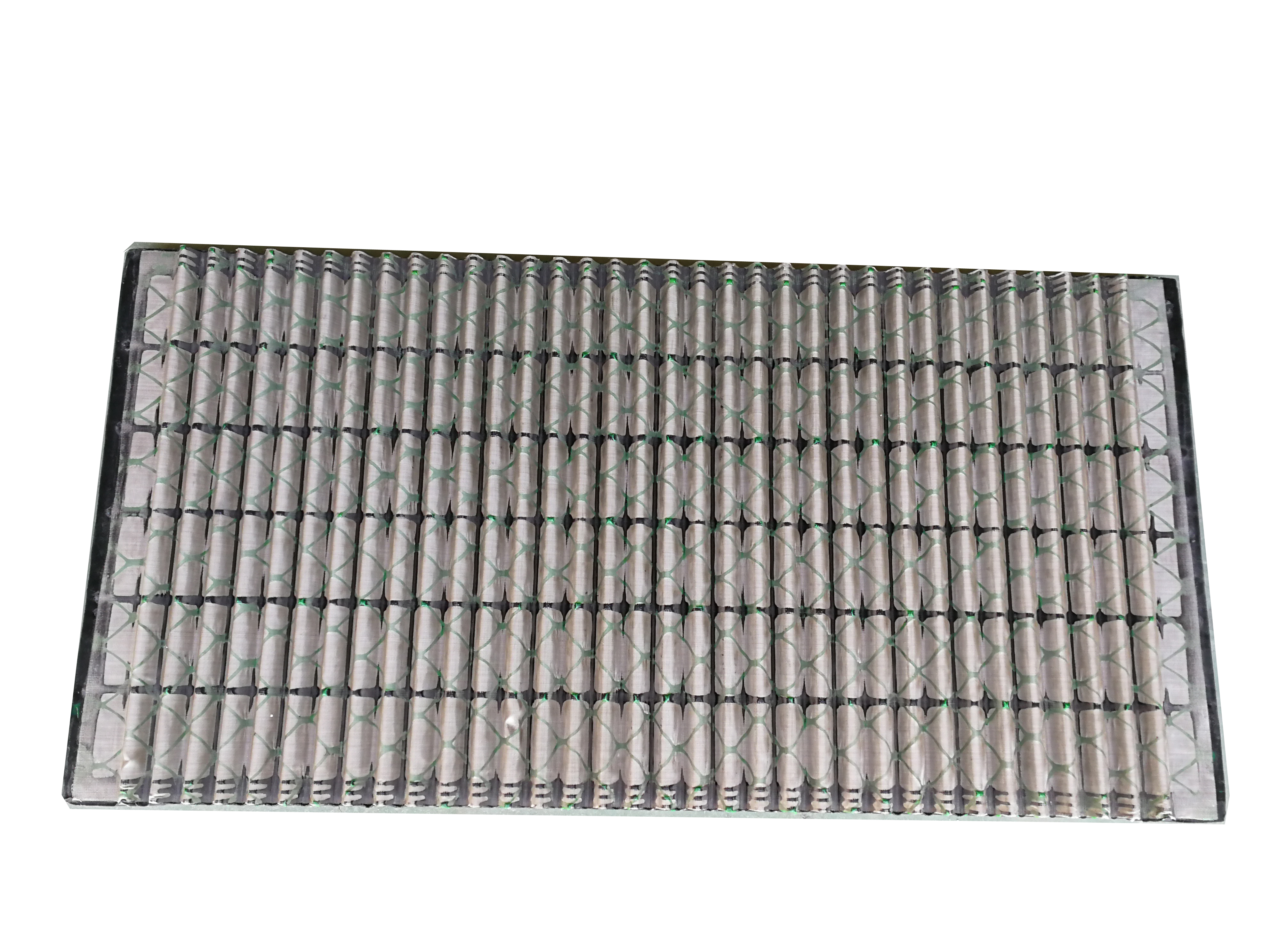

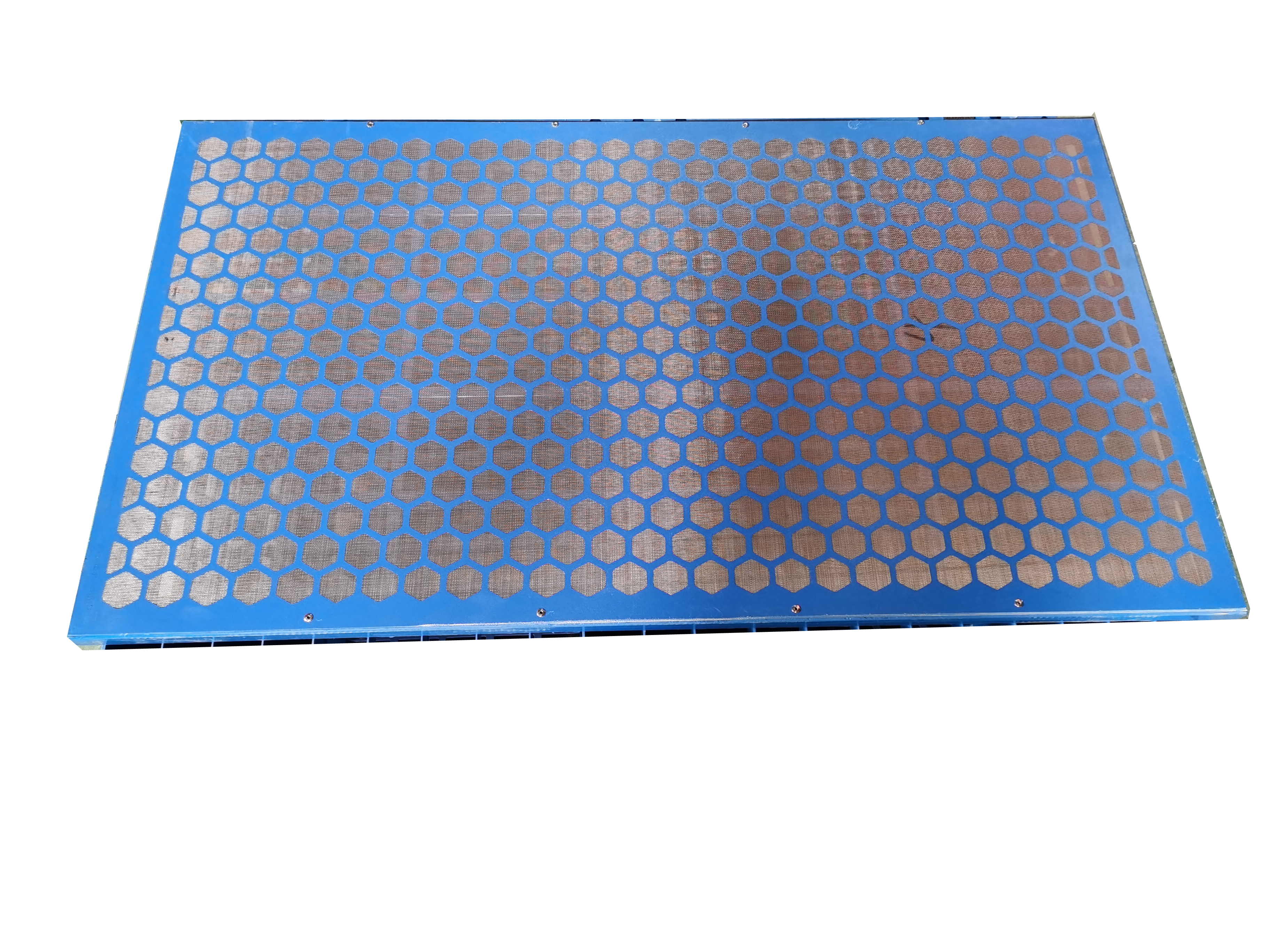

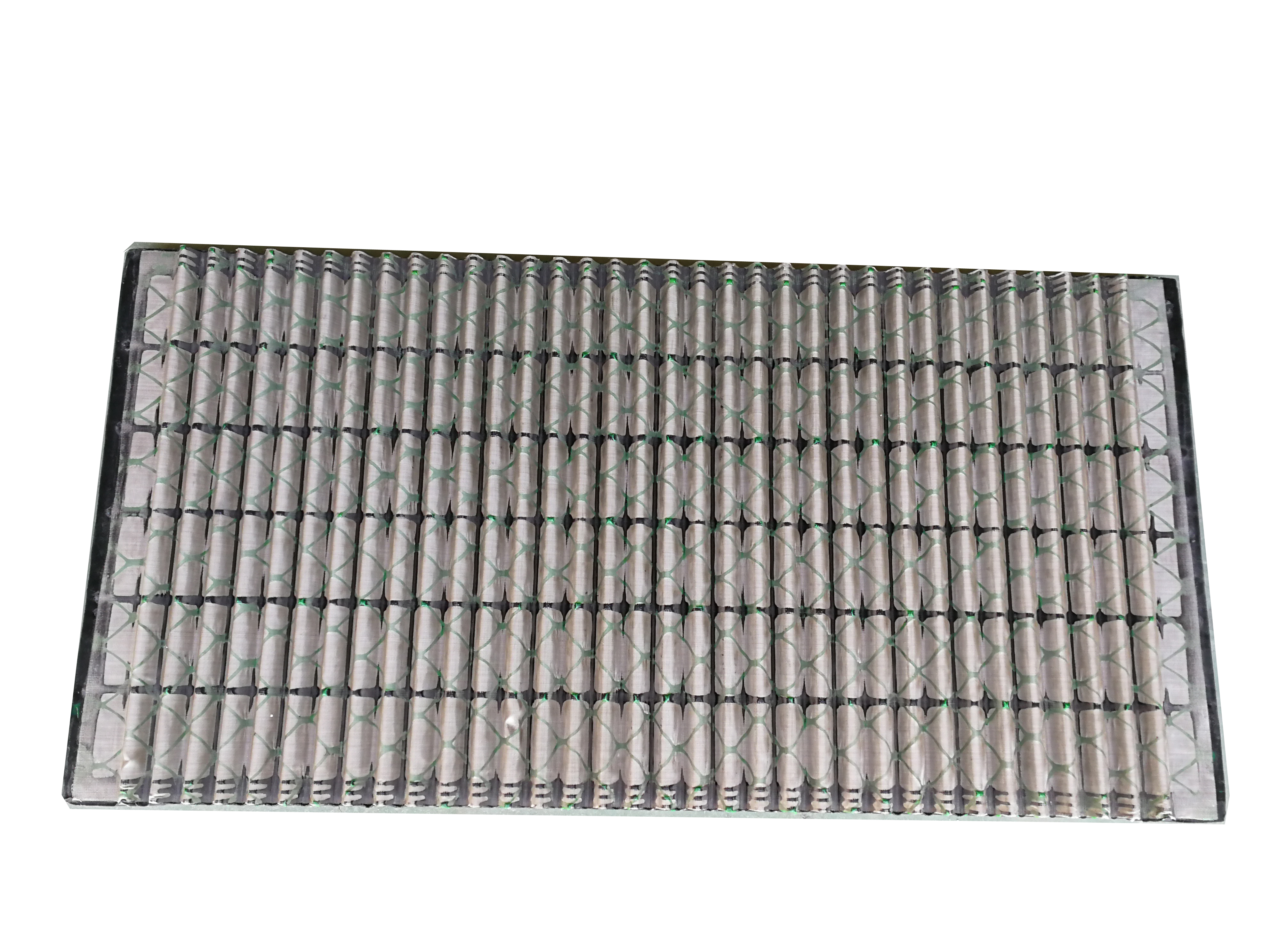

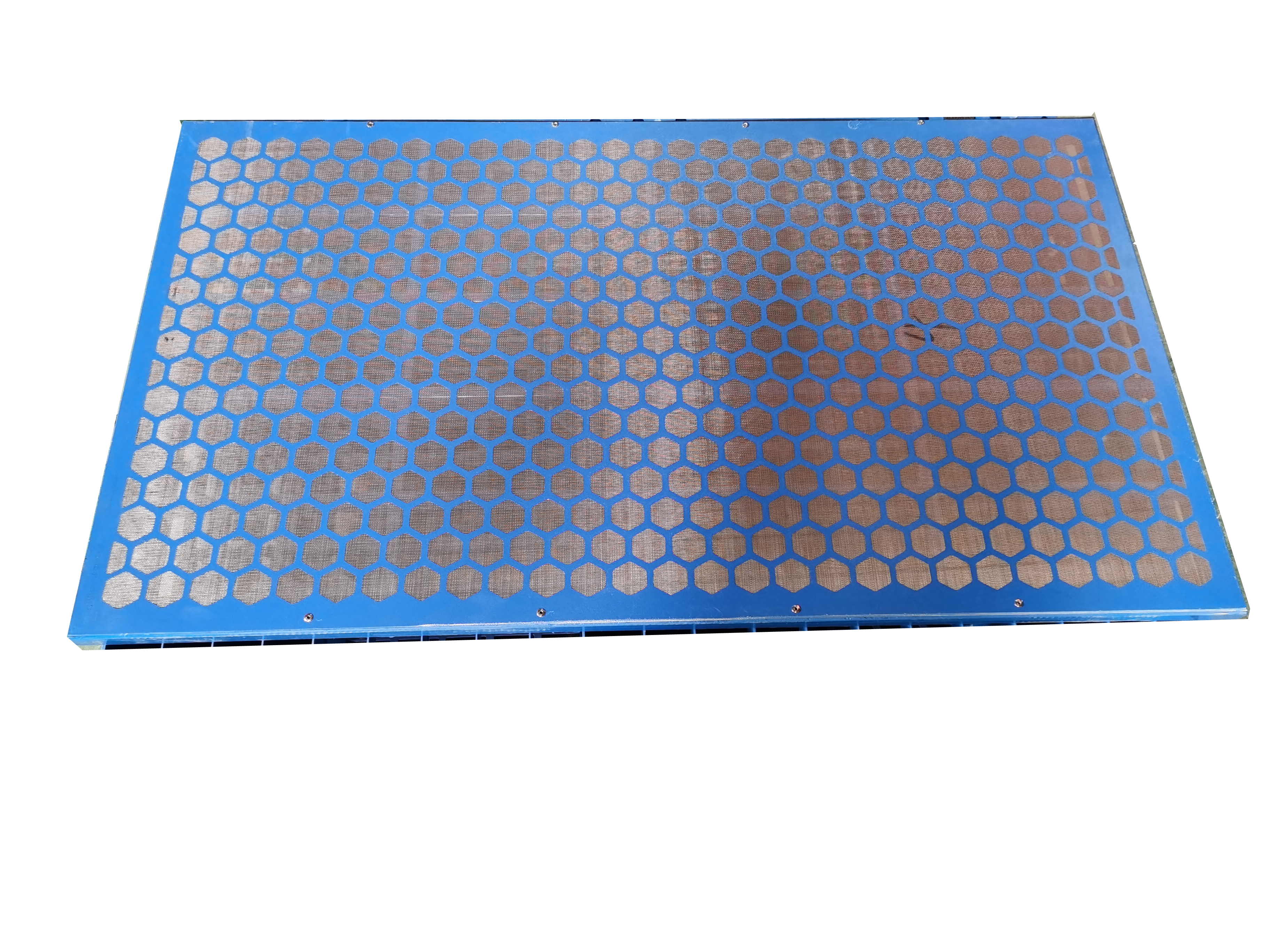

As a specialized manufacturer of “Kangertong Brand” series wire mesh, we produce a wide range of oil shale shaker screens, composite shaker screens, stainless steel wire mesh, steel grating, expanded and perforated metal mesh, welded wire mesh, barb wire, razor wire, and fencing products. Every screen is built to meet or exceed API RP 13C standards.

High-Performance Replacement Shaker Screens for All Major Brands

Engineered for Performance, Built for Longevity

All screens meet or exceed API standards for performance and reliability.

Backed by over a decade of innovation and manufacturing excellence.

Trusted by clients in the Middle East, Europe, Americas, and Asia.

Pretensioned, repairable designs extend screen life and reduce costs.

We produce replacement screens for Derrick, SWACO, Brandt, KEMTRON, SCOMI, FSI, Vortex, and other major shale shaker brands.

Yes, all our shaker screens are designed and tested to meet or exceed API RP 13C standards for performance and durability.

We use high-quality stainless steel 304, 316, and 316L for mesh, and Q235 steel or composite materials for frames. Polyurethane and galvanized steel are also used for specific applications.

Yes, we offer customization in mesh size, frame type, layering, and dimensions to meet your operational requirements.

Standard orders are processed within 7–15 days. Urgent deliveries can be arranged upon request.

Contact us for product inquiries, quotes, or technical support.

Email: sales@ketshakerscreen.com

Phone: 0086-13663386076

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info