Our Products

Explore our comprehensive range of thermal management and precision machining solutions engineered for performance and reliability.

Extrusion Heat Sink

High-efficiency aluminum heatsinks ideal for natural and forced convection cooling in power electronics and LED applications.

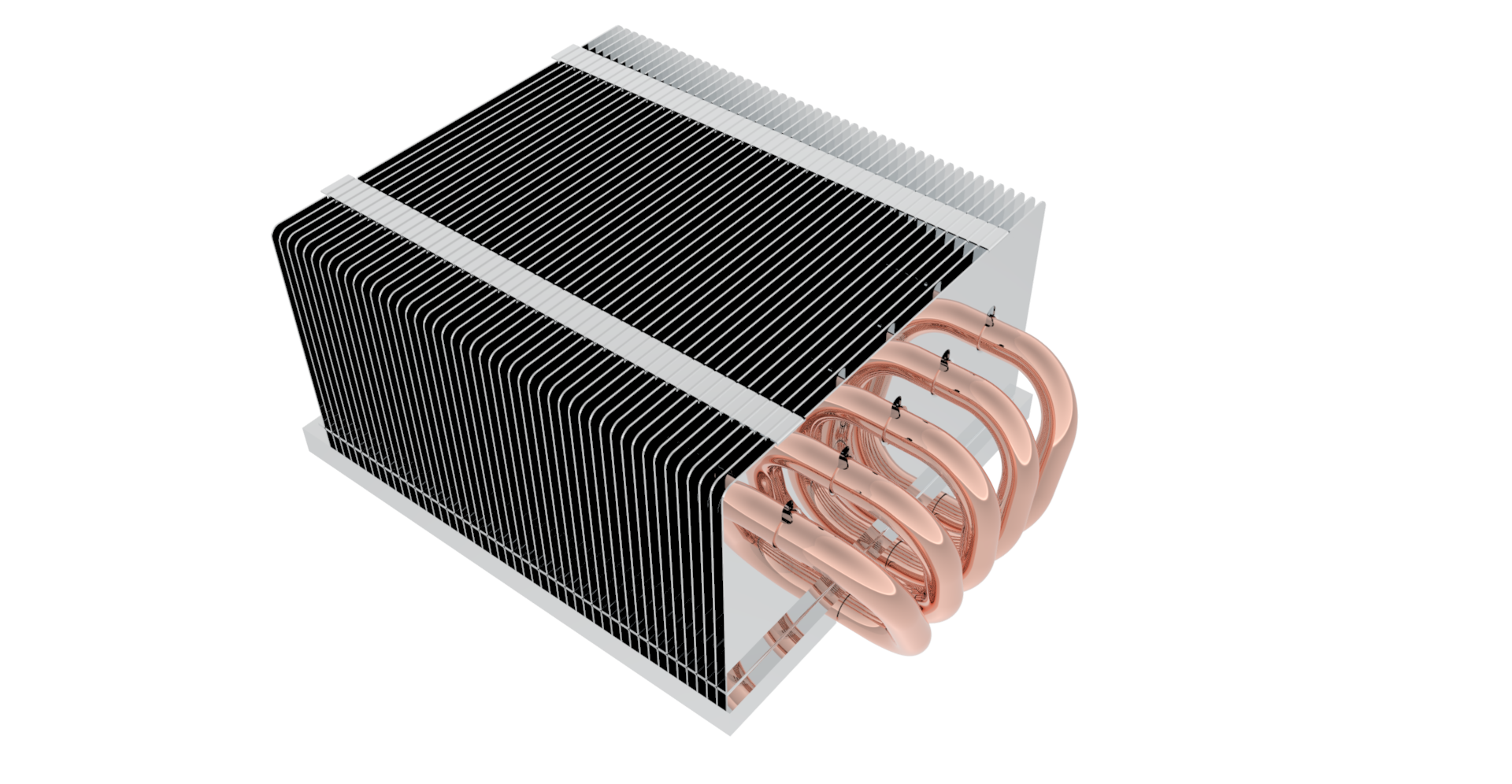

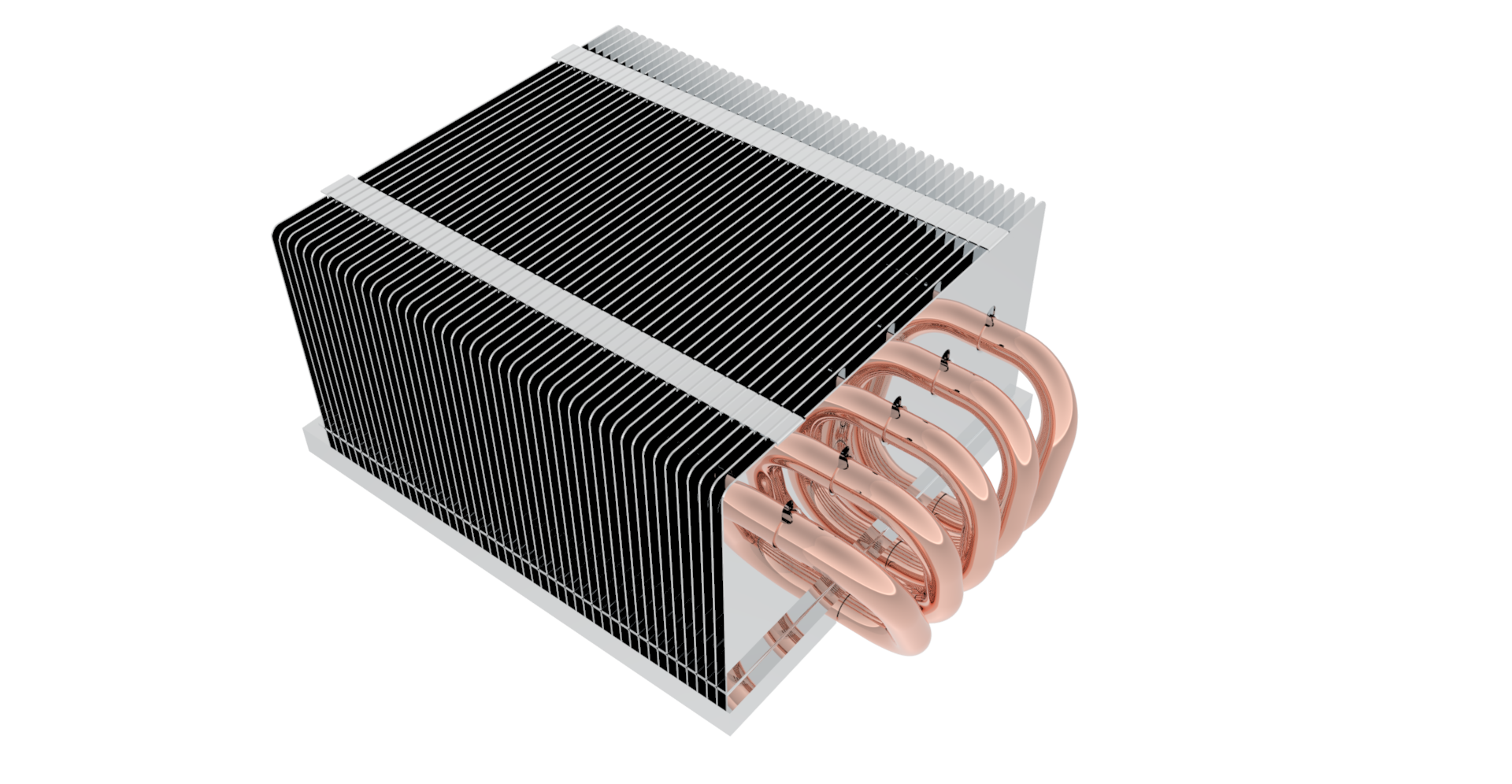

Heat Pipe Thermal System

Advanced two-phase cooling technology for high-heat-flux applications such as CPUs, GPUs, and power modules.

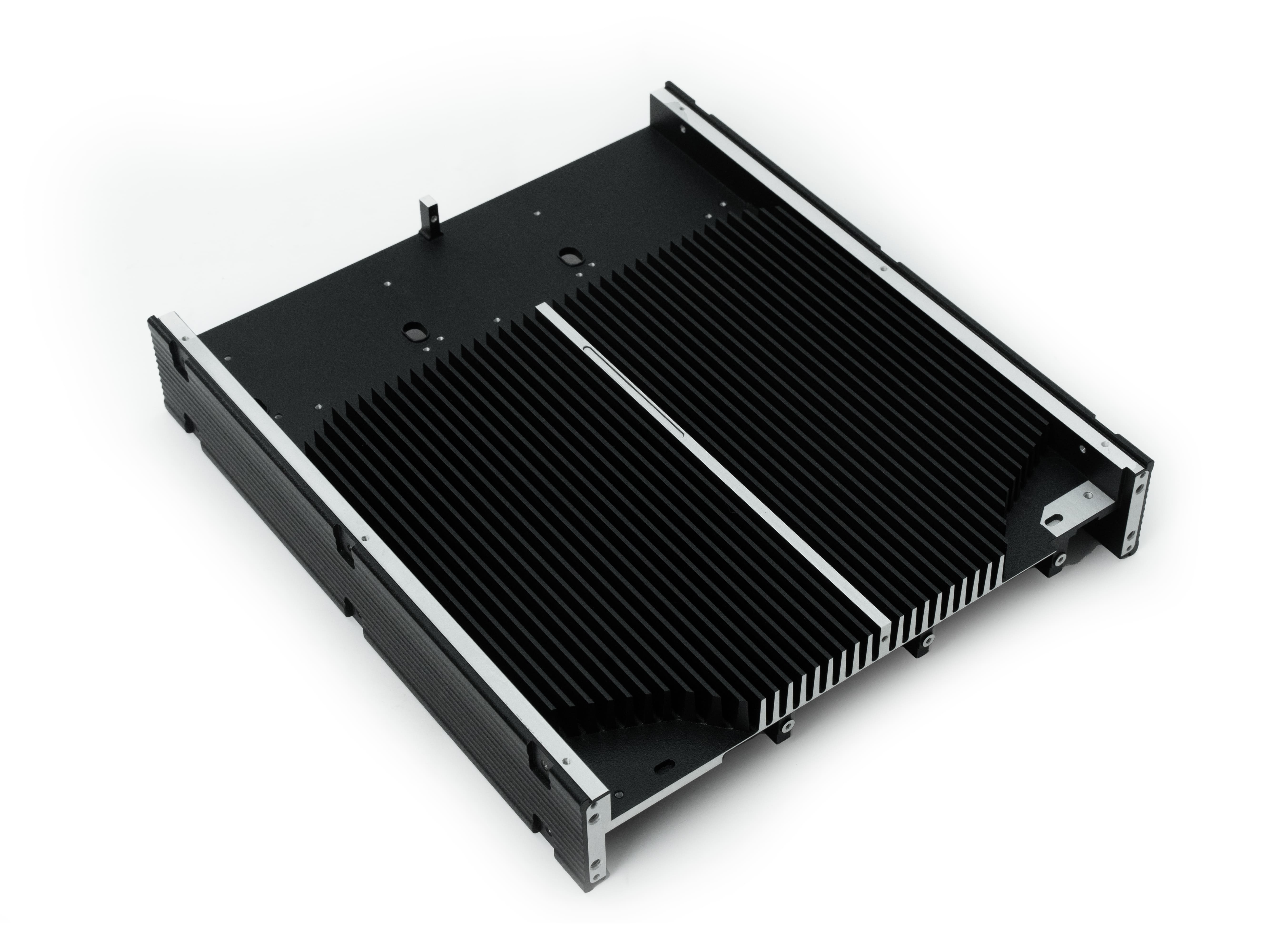

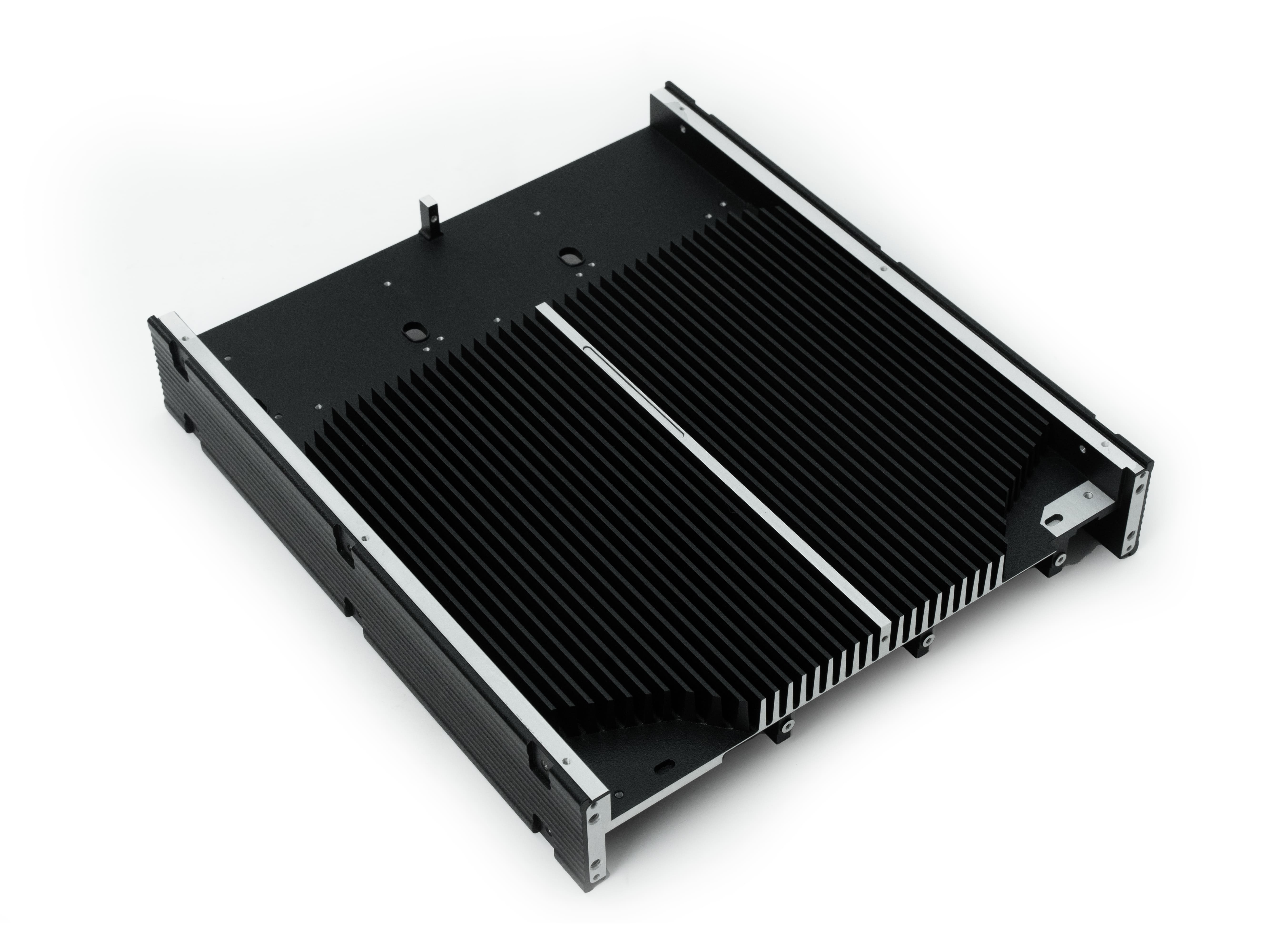

Skiving Fin Heat Sink

Ultra-thin, high-density fins for maximum surface area and superior thermal performance in compact spaces.

CPU/GPU Water Block

Precision-machined copper water blocks for direct die cooling in high-performance computing and gaming systems.

FSW Liquid Cold Plate

Friction stir welding technology ensures leak-proof joints and high structural integrity for demanding thermal environments.

Bonded Fin Heat Sink

High-aspect-ratio fins bonded into base plates for optimized airflow and thermal performance in confined spaces.

Vacuum Brazing Liquid Cold Plate

Hermetically sealed cold plates with complex internal channels for high-reliability applications in aerospace and medical.

CNC Machining Parts

Custom aluminum and stainless steel components with tight tolerances for industrial, medical, and consumer electronics.

Cold Forging Heat Sink

High-strength, fine-grained structure achieved through cold forging process for enhanced thermal conductivity.

Die-Casting Heat Sink

Cost-effective mass production method for complex geometries in consumer electronics and lighting applications.