About Kingsman BlowTech

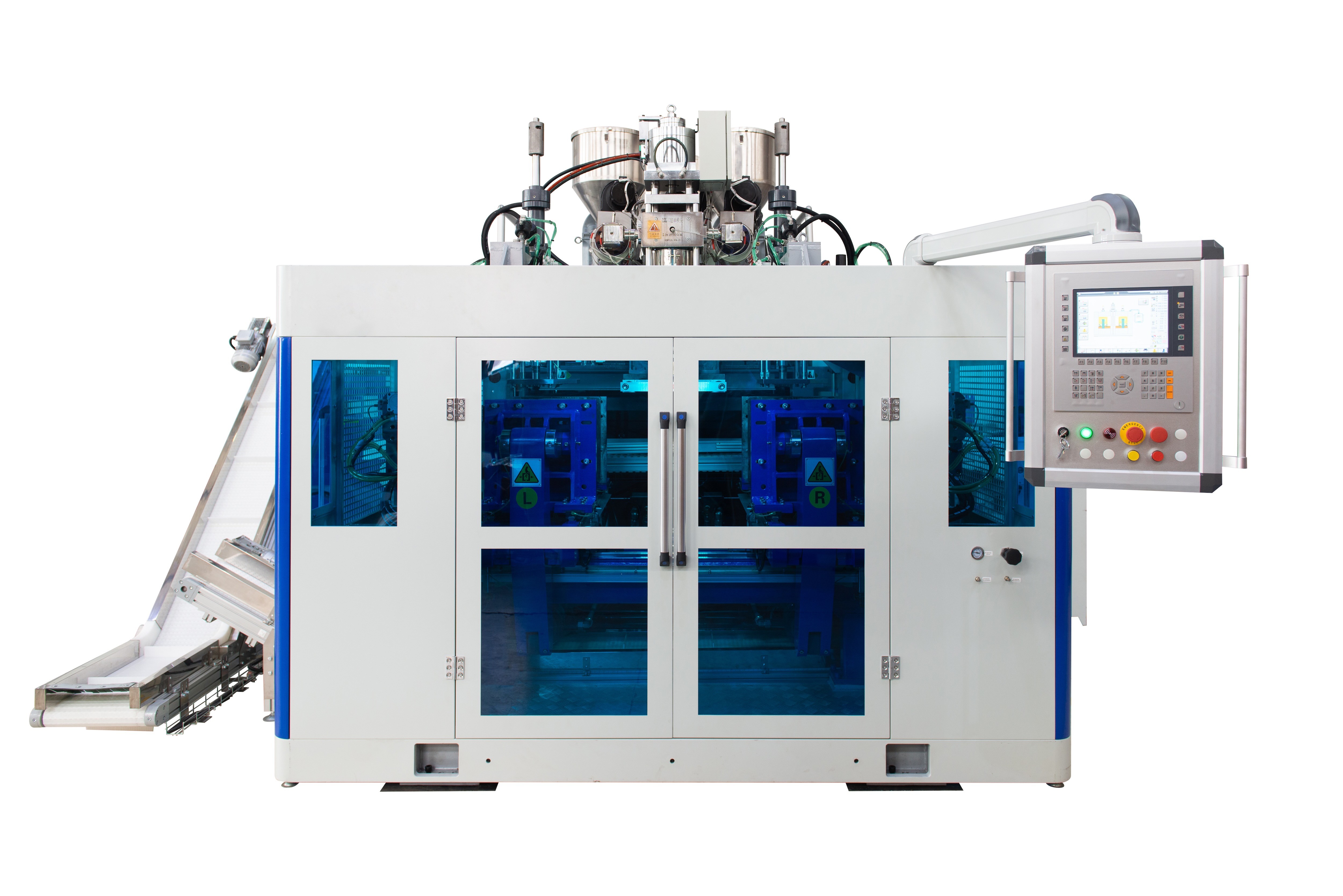

KINGSMAN (Zhangjiagang) Mechanical and Equipment Co., Ltd. is a leading manufacturer of extrusion blow molding machines based in China. With advanced processing equipment and a strict quality control system, we deliver reliable, high-efficiency machinery for plastic container production.

Our machines are engineered for durability, precision, and energy efficiency—ideal for producing jerry cans, plastic drums, water tanks, bottles, and multi-layer containers used across chemical, food, beverage, and industrial sectors.

- ISO & RoHS Compliant Manufacturing

- In-House R&D and Design Team

- Global Export to 50+ Countries

- 24/7 Technical Support & After-Sales Service