About NKT Tooling

Founded in 2009, Ningbo NKT Tooling Co., Ltd. is a leading manufacturer of high-precision die casting molds in China.

Our Expertise

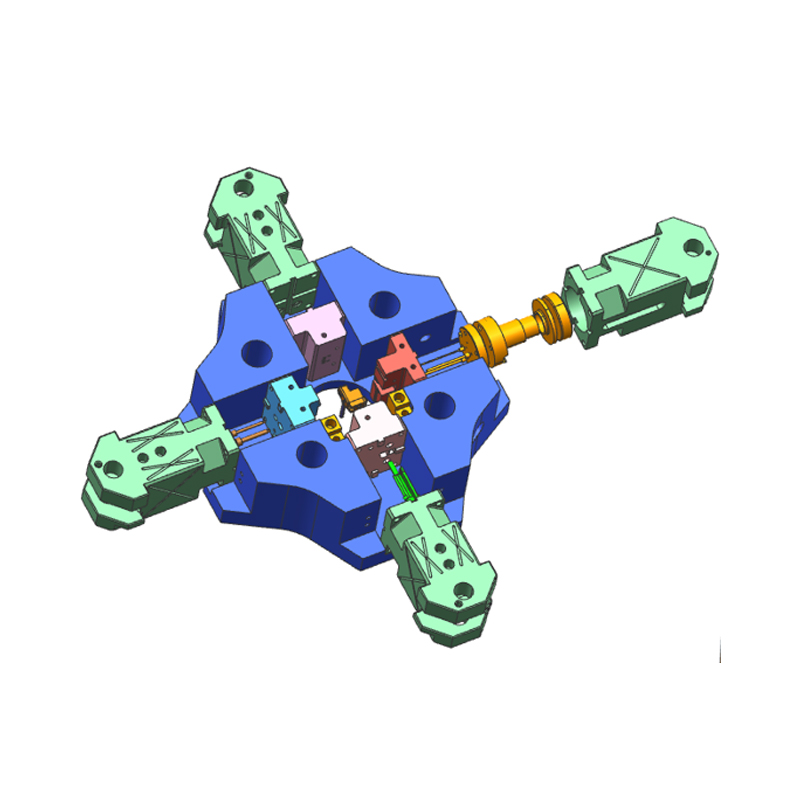

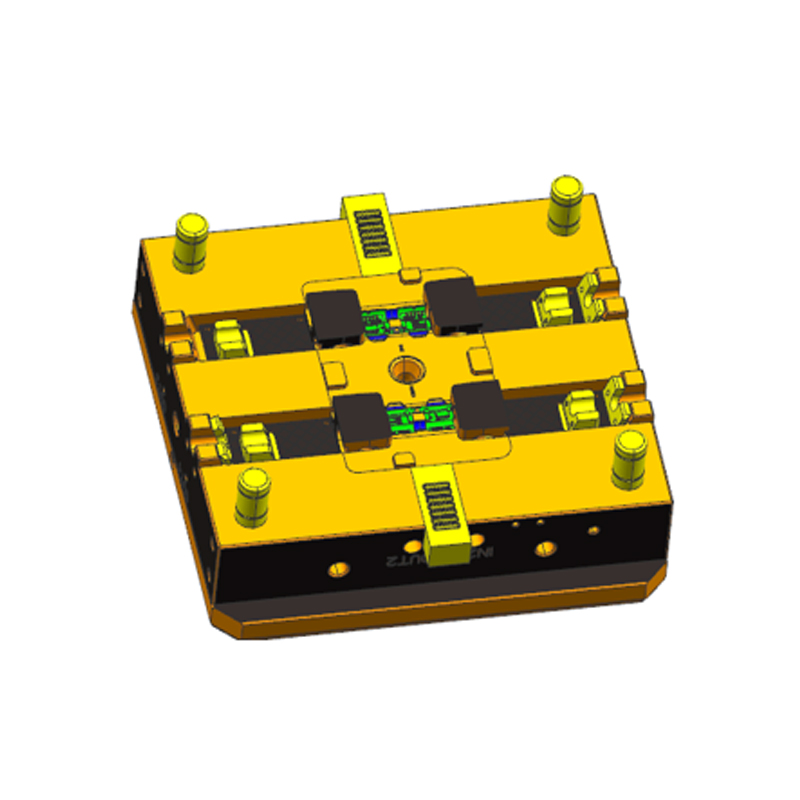

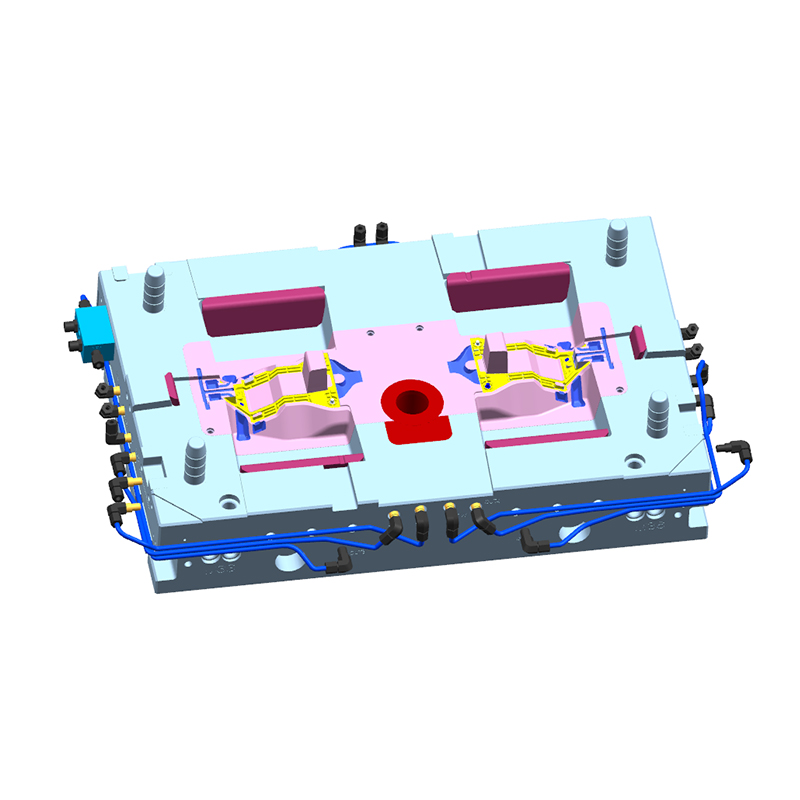

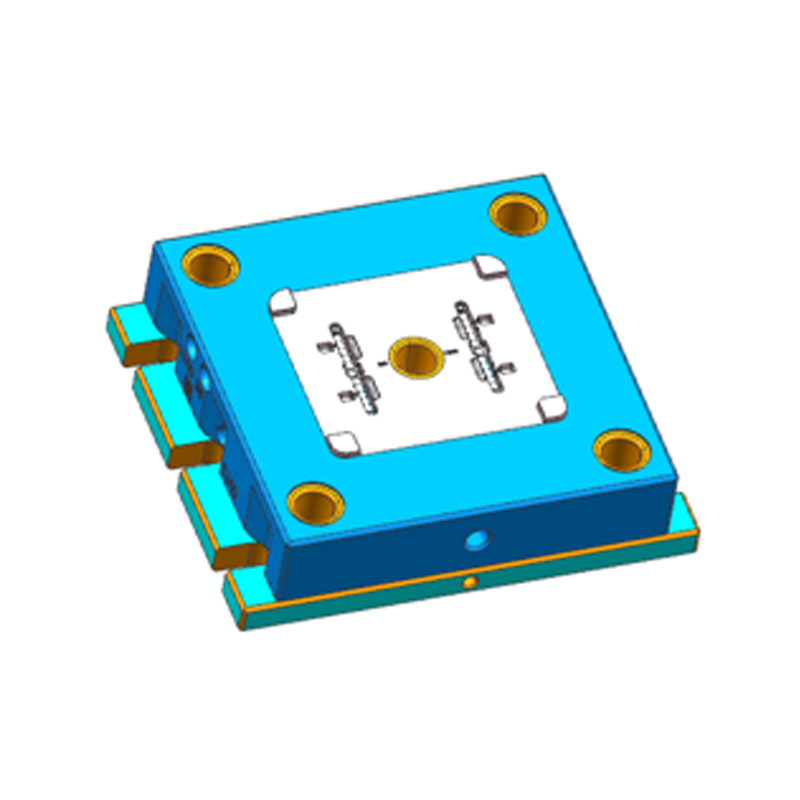

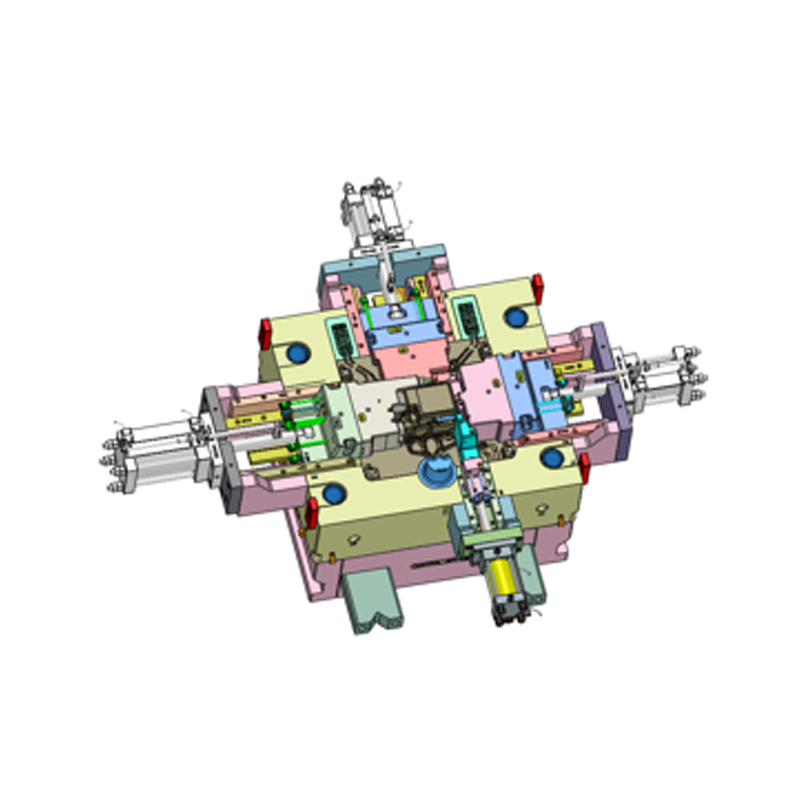

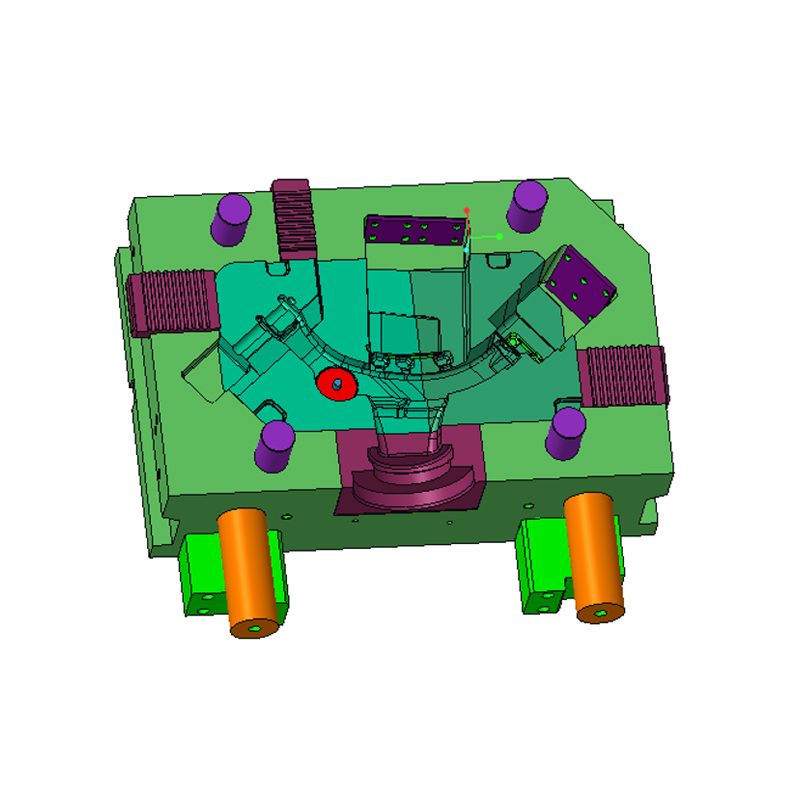

We specialize in the design and manufacturing of aluminum, magnesium, and zinc alloy molds, as well as extrusion casting molds. Our products are widely used across the automotive, communications, industrial, healthcare, and sports equipment industries.

With a modern manufacturing facility covering 6,000 square meters and a team of over 80 professionals—including 15 senior engineers—we produce more than 300 high-precision molds annually.