About Us

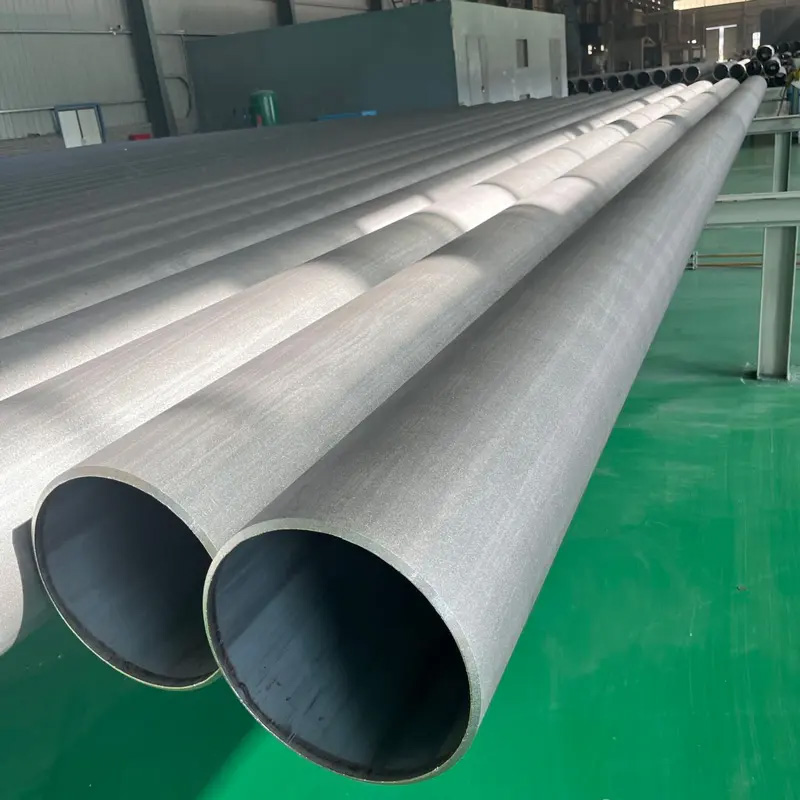

Cangzhou Spiral Steel Pipes Group Co., Ltd.

Founded in 1993, we are a leading Chinese manufacturer of Spiral Steel Pipes and pipe coating products. Located in Cangzhou City, Hebei Province, our 350,000 square meter facility houses 13 production lines for spiral steel pipes and 4 dedicated lines for anticorrosion & thermal insulation.

With 680 employees and annual production of 400,000 tons, we deliver WUZHOU-branded products that meet international standards including API Spec 5L, ASTM A139, ASTM A252, and EN 10219. Our output value reaches 1.8 billion Yuan annually.

We serve municipal water and wastewater systems, long-distance oil and gas transmission, and structural piling applications worldwide.