Advanced Plastic Extrusion & Recycling Machinery

High-efficiency plastic extrusion lines and recycling systems engineered for durability, precision, and maximum output. Trusted by manufacturers in over 50 countries worldwide.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

High-efficiency plastic extrusion lines and recycling systems engineered for durability, precision, and maximum output. Trusted by manufacturers in over 50 countries worldwide.

A leading manufacturer of plastic processing machinery with decades of engineering excellence, delivering innovative extrusion and recycling solutions globally.

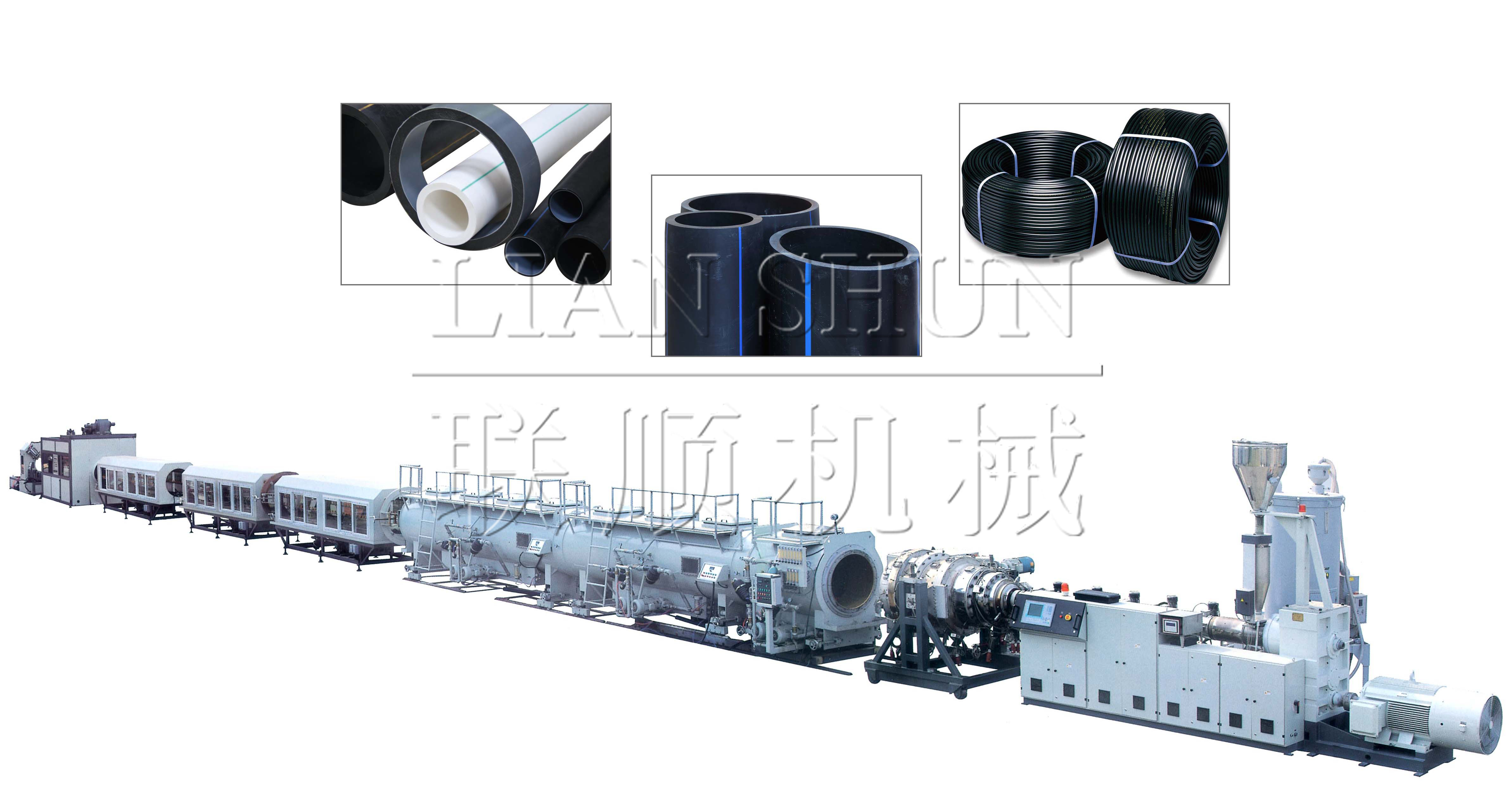

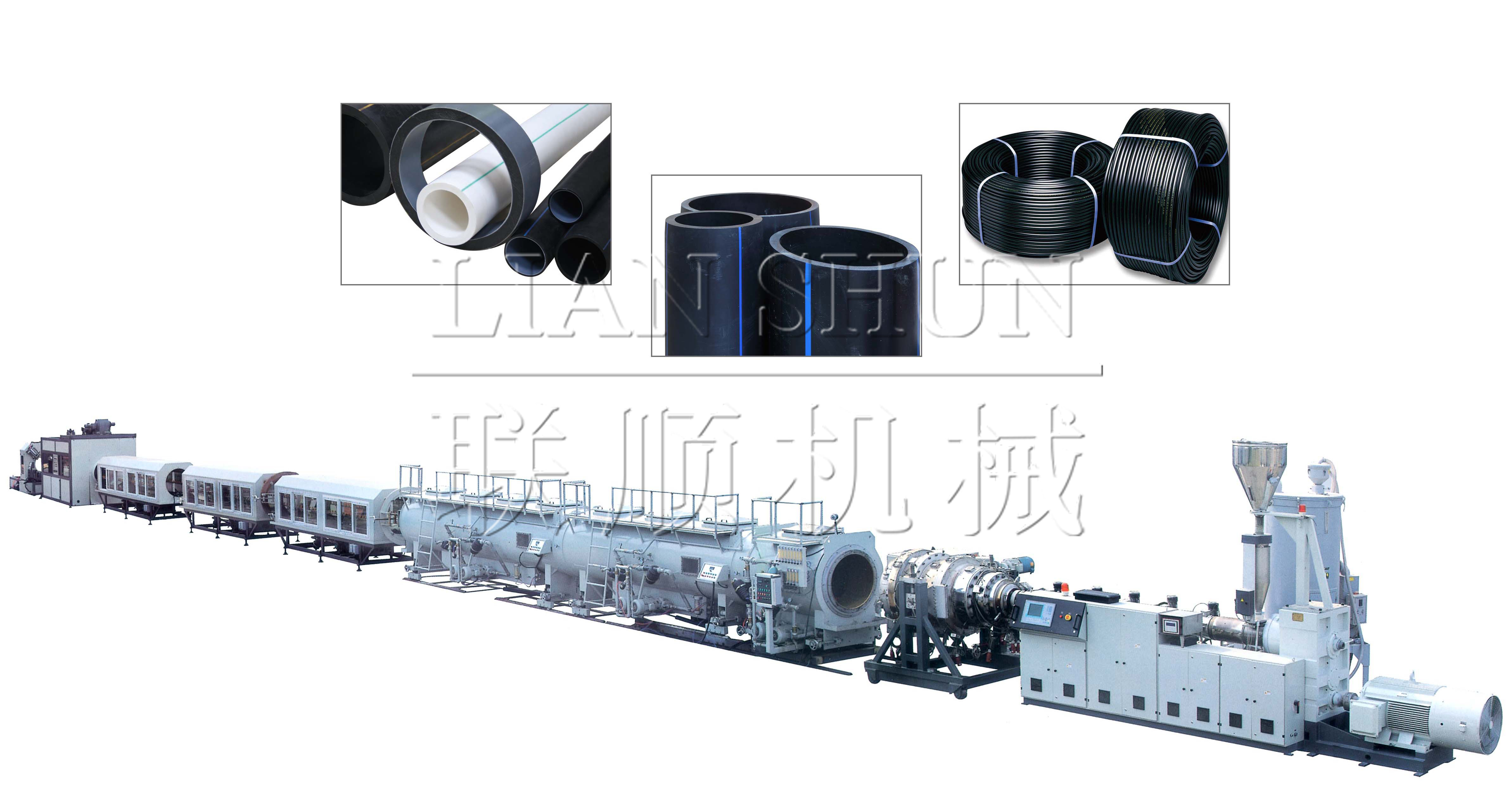

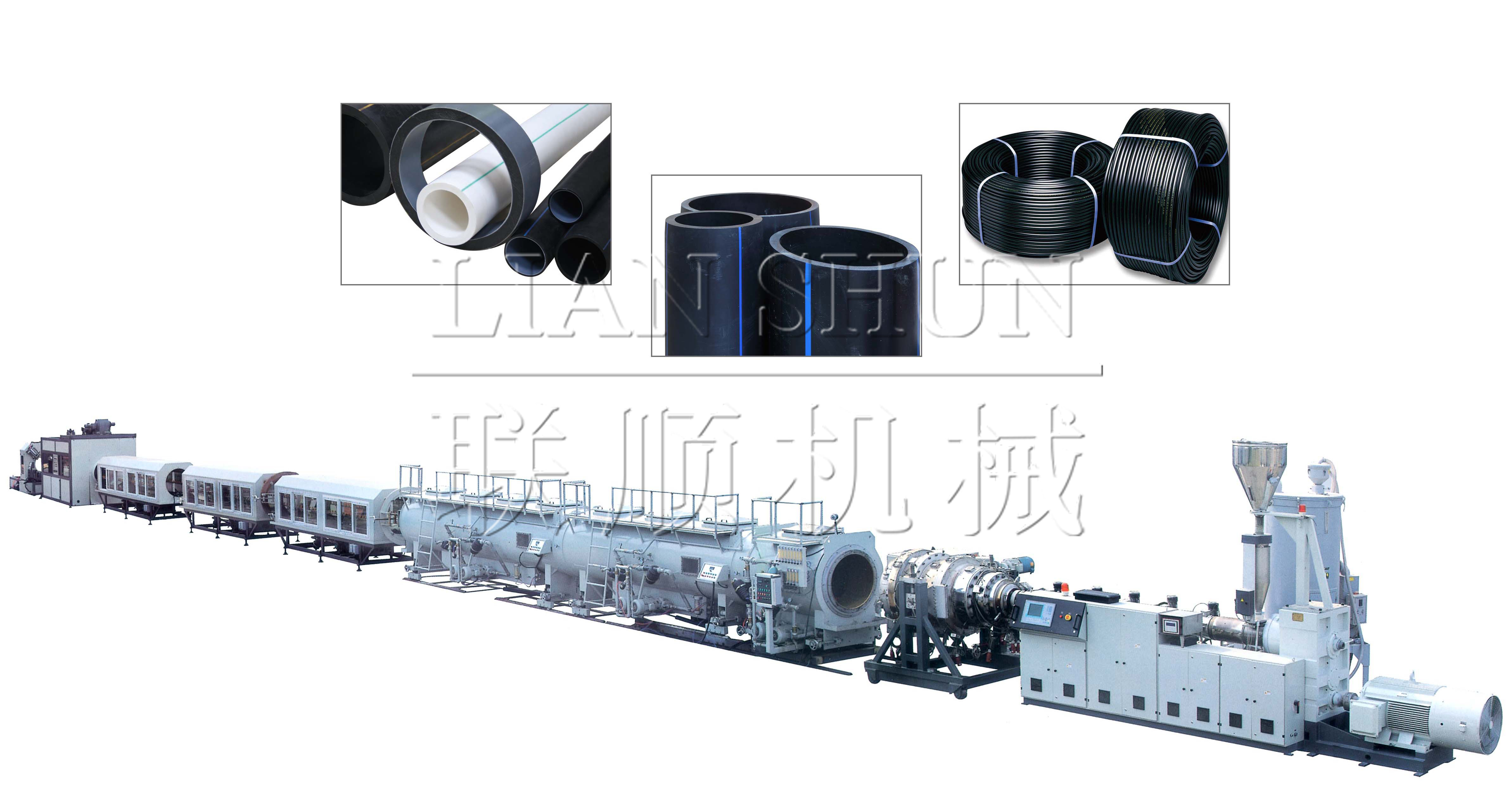

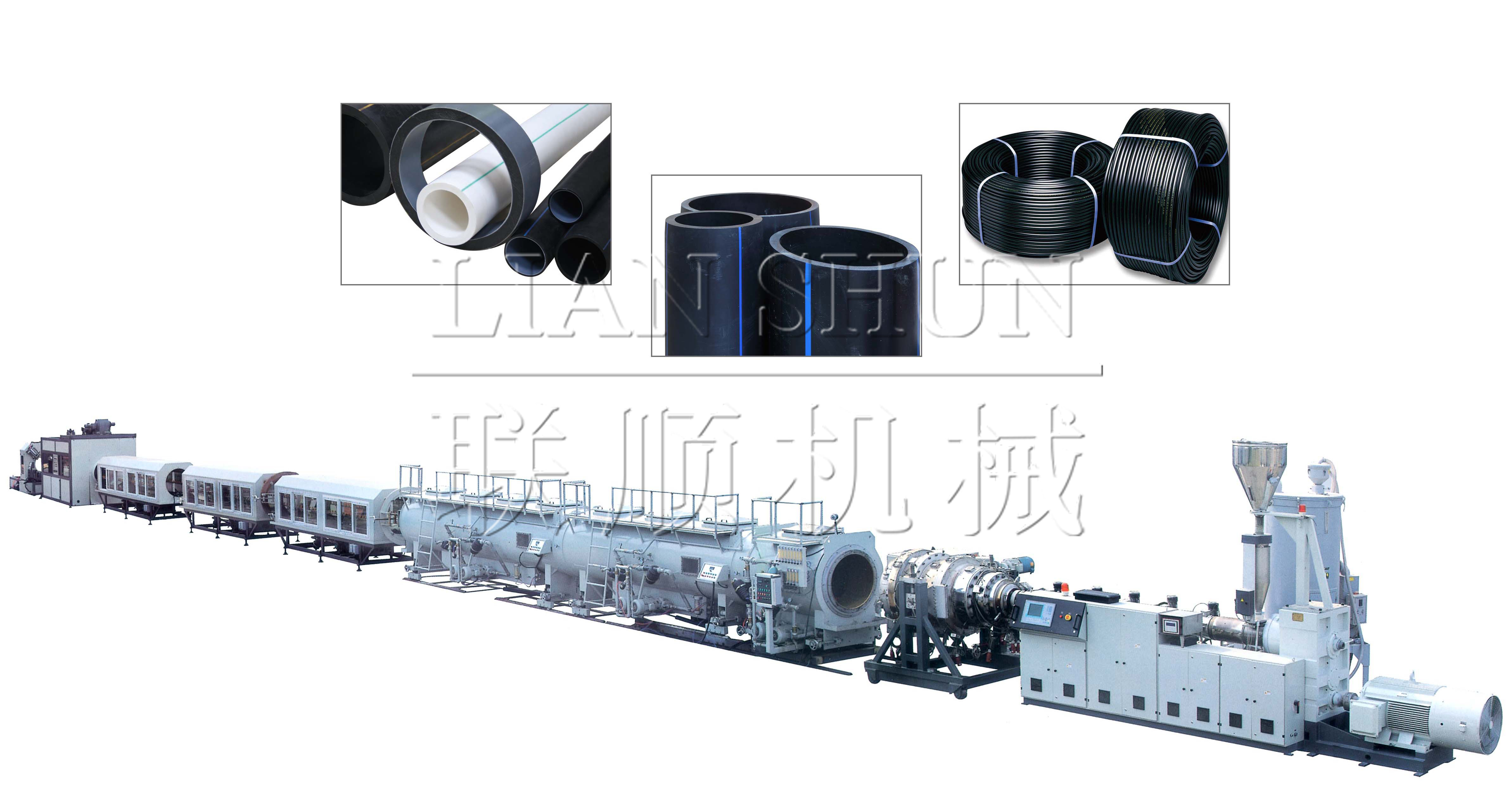

LSTWIN Machine, operating under LianShun, designs and manufactures high-performance plastic extrusion and recycling systems used in pipe, profile, sheet, and pellet production. Our machines are built for reliability, energy efficiency, and long operational life.

With advanced single and twin-screw extruders, automated calibration tanks, and full-line integration capabilities, we serve industries ranging from construction and agriculture to telecommunications and waste management.

Engineered for performance, durability, and maximum output across diverse plastic applications.

For HDPE, PP, PVC pipes from Φ20–1600mm. Used in water, gas, irrigation, and cable conduits.

Ideal for PVC pipe and profile extrusion with excellent plasticization and low shear.

Produces decorative and structural PVC/WPC panels for doors, ceilings, and wall cladding.

For drainage, sewage, and irrigation systems. High automation and stable extrusion.

Versatile for pipes, profiles, sheets, and pelletizing. Low energy, high plasticization.

Precision calibration for consistent pipe diameter and surface finish.

Cleans and prepares post-consumer film, bottles, and containers for pelletizing.

Full recycling line for PET bottles into clean, dry flakes or pellets.

For window frames, door trims, decking, and WPC products.

Grinds plastic scraps into fine powder for reuse in extrusion or injection molding.

Robust size reduction for pipes, profiles, films, and large plastic parts.

Ensures uniform material blending before extrusion for consistent product quality.

Heavy-duty construction with hardened gears and wear-resistant components for 24/7 operation.

Optimized motor and heating systems reduce power consumption by up to 30%.

PLC control, touch screen HMI, and smart diagnostics for seamless operation.

Installation, training, and remote assistance available worldwide.

From concept to commissioning, we deliver complete plastic processing lines.

We design and install complete systems including extruders, dies, calibration, cooling, haul-off, cutting, and stacking — fully integrated and tested.

Comprehensive recycling solutions from shredding to pelletizing, including material handling, washing, drying, and extrusion.

Our machines handle PE, PP, PVC, PET, PS, ABS, and bioplastics. Special configurations are available for WPC and foam extrusion.

Yes, we offer on-site installation, commissioning, and operator training. Remote support is also available via video call.

Typical lead time is 45–60 days after order confirmation, depending on machine type and customization.

Absolutely. We offer full customization including output capacity, automation level, material feeding, and downstream equipment.

For product inquiries, pricing, or technical support, visit our official website to contact the LSTWIN team directly.

Visit Official WebsiteNotice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info