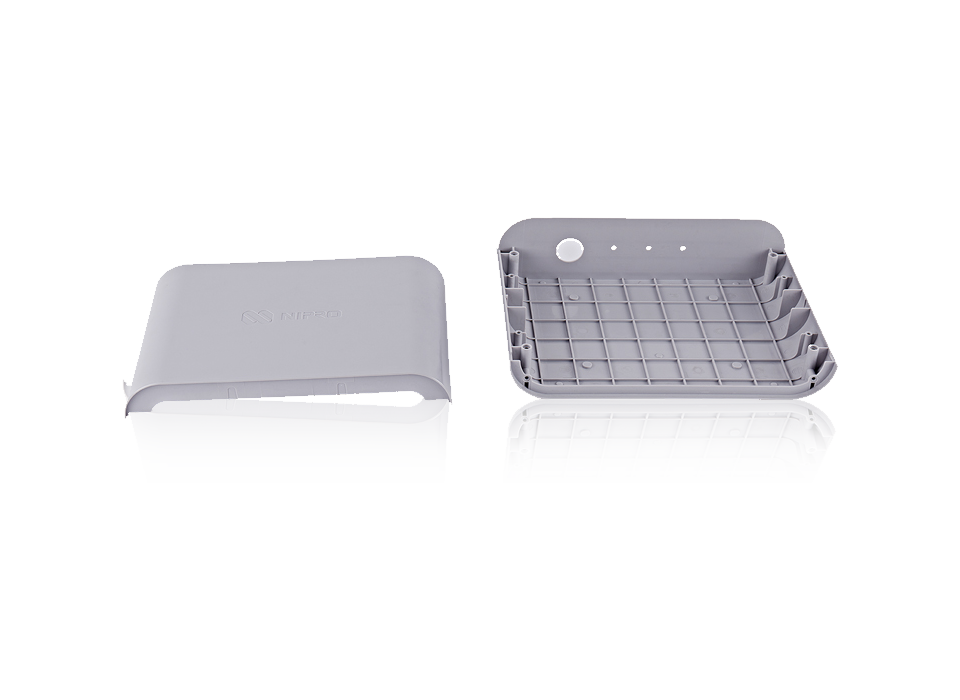

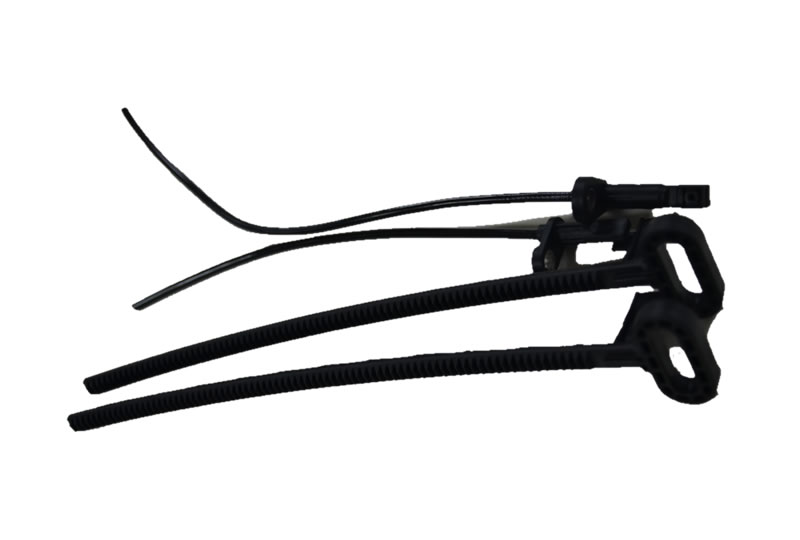

Precision Plastic Molding &

Tooling Solutions

Mars Plastic Mould Co., Ltd. delivers high-performance injection molding, precision tool making, and engineering services for automotive, industrial, consumer electronics, and medical applications. With advanced capabilities in tight-tolerance molds and complex part production, we ensure quality, durability, and reliability.