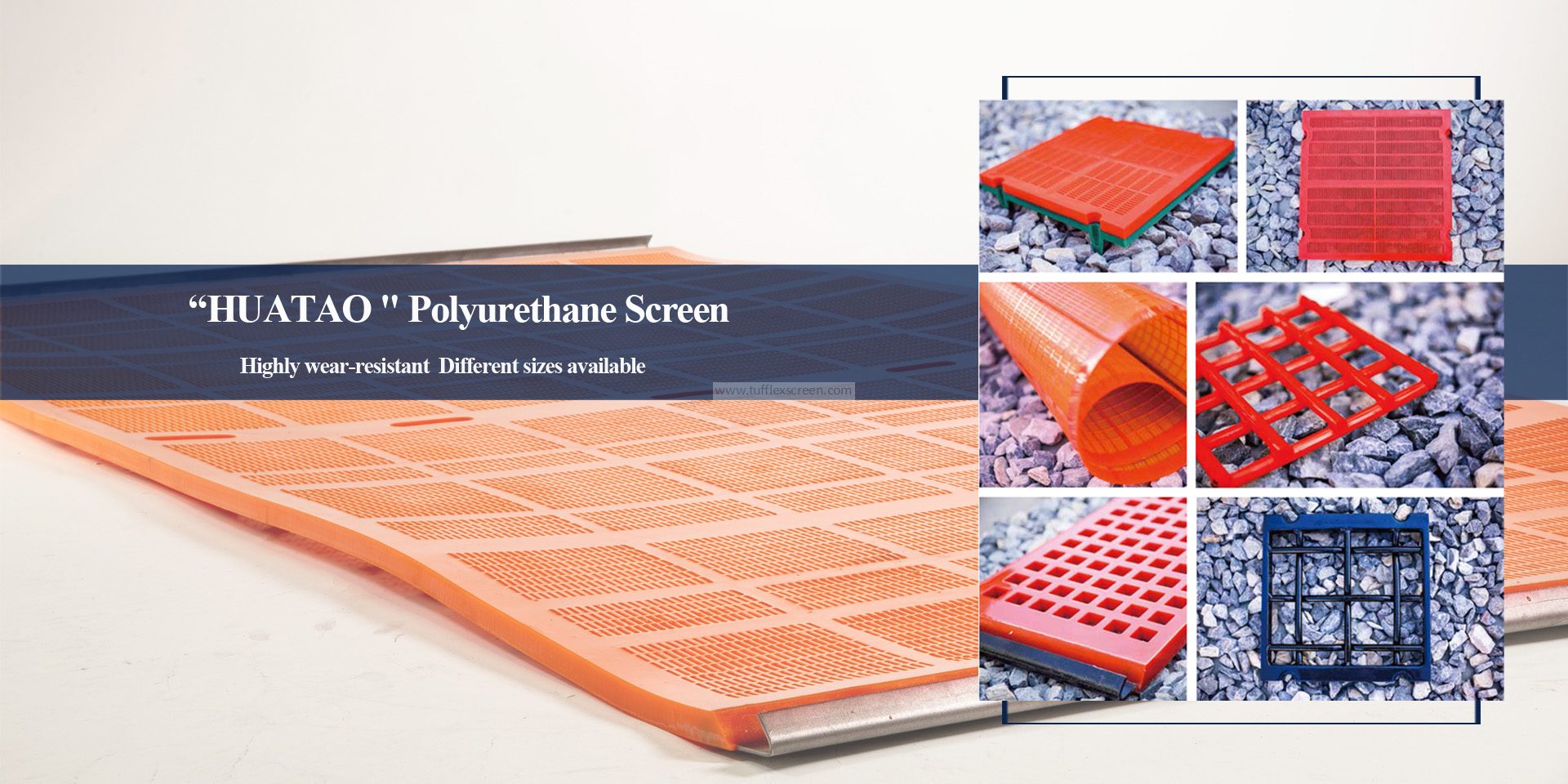

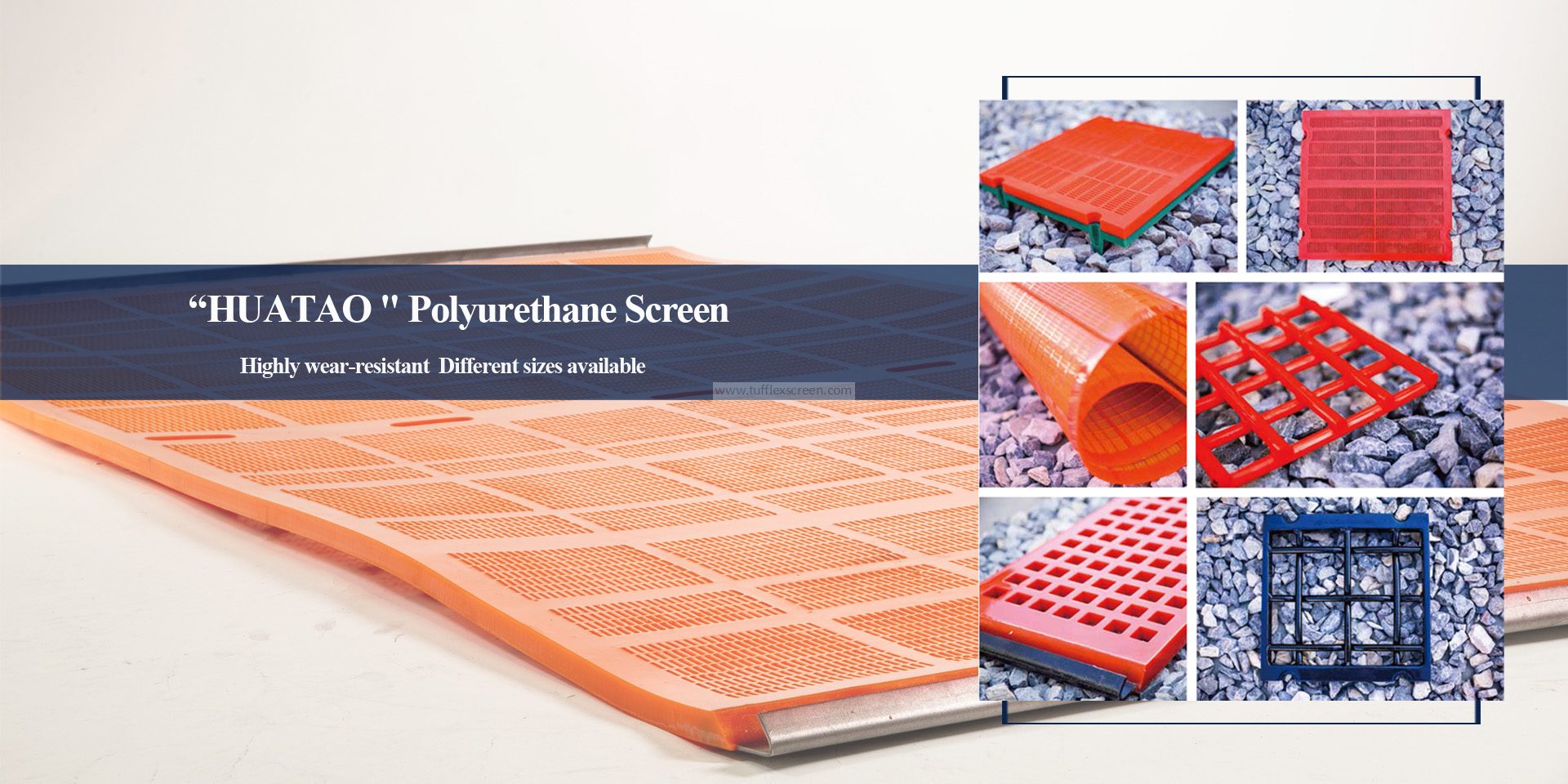

Premium Mineral Screening Solutions

High-performance polyurethane screen panels, vibrating screens, and mineral processing equipment engineered for durability, efficiency, and maximum uptime in mining and aggregate industries.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

High-performance polyurethane screen panels, vibrating screens, and mineral processing equipment engineered for durability, efficiency, and maximum uptime in mining and aggregate industries.

HUATAO GROUP is a leading manufacturer and supplier of high-quality mineral screening equipment and parts. With years of experience in the mining and mineral processing industry, we specialize in polyurethane screen panels, vibrating screens, shale shakers, crushers, and beneficiation machinery.

Our products are designed for superior wear resistance, anti-clogging performance, and extended service life—reducing downtime and maintenance costs for our clients worldwide.

Engineered for performance, durability, and precision—our mineral screening solutions are trusted by mining, quarrying, and aggregate processing industries worldwide.

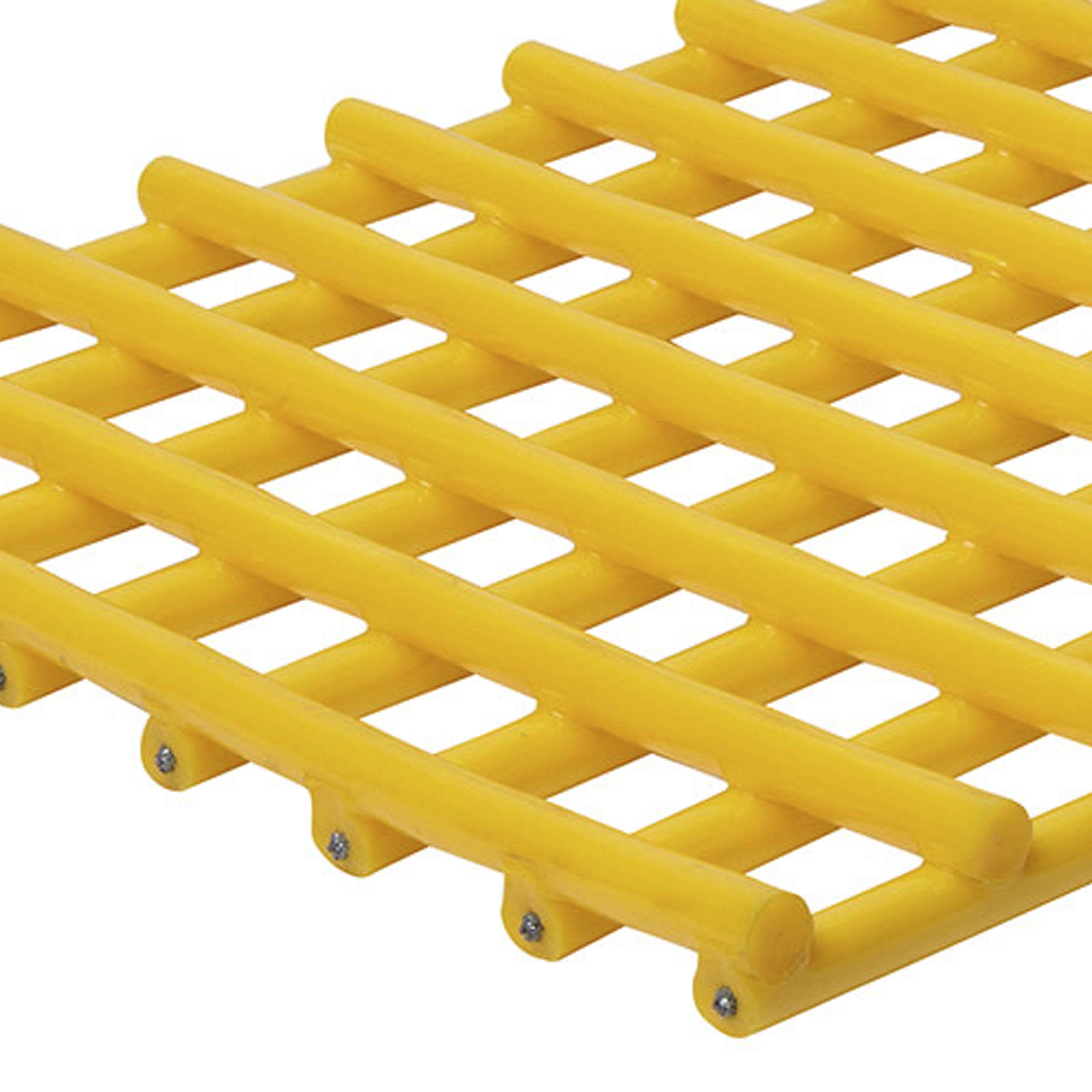

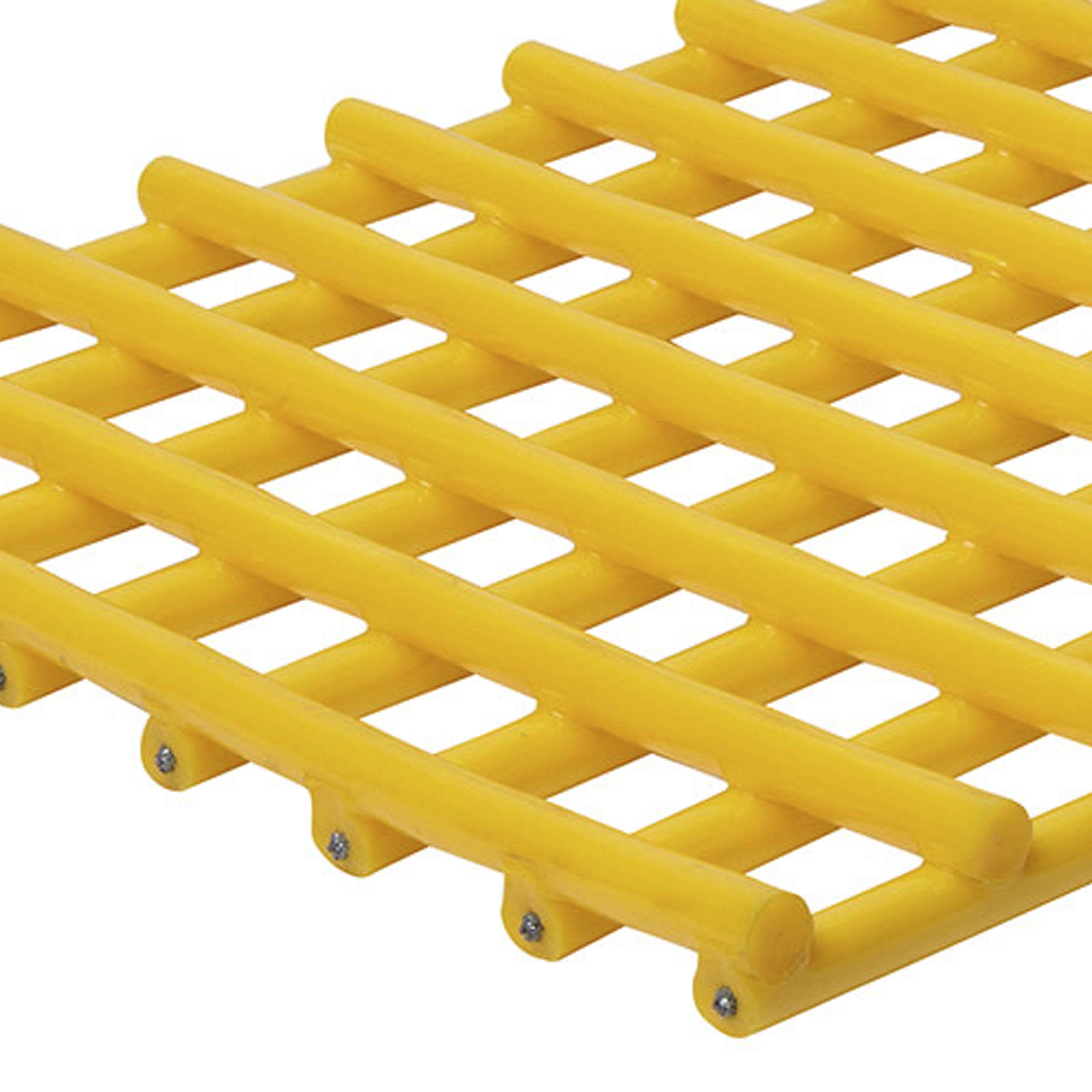

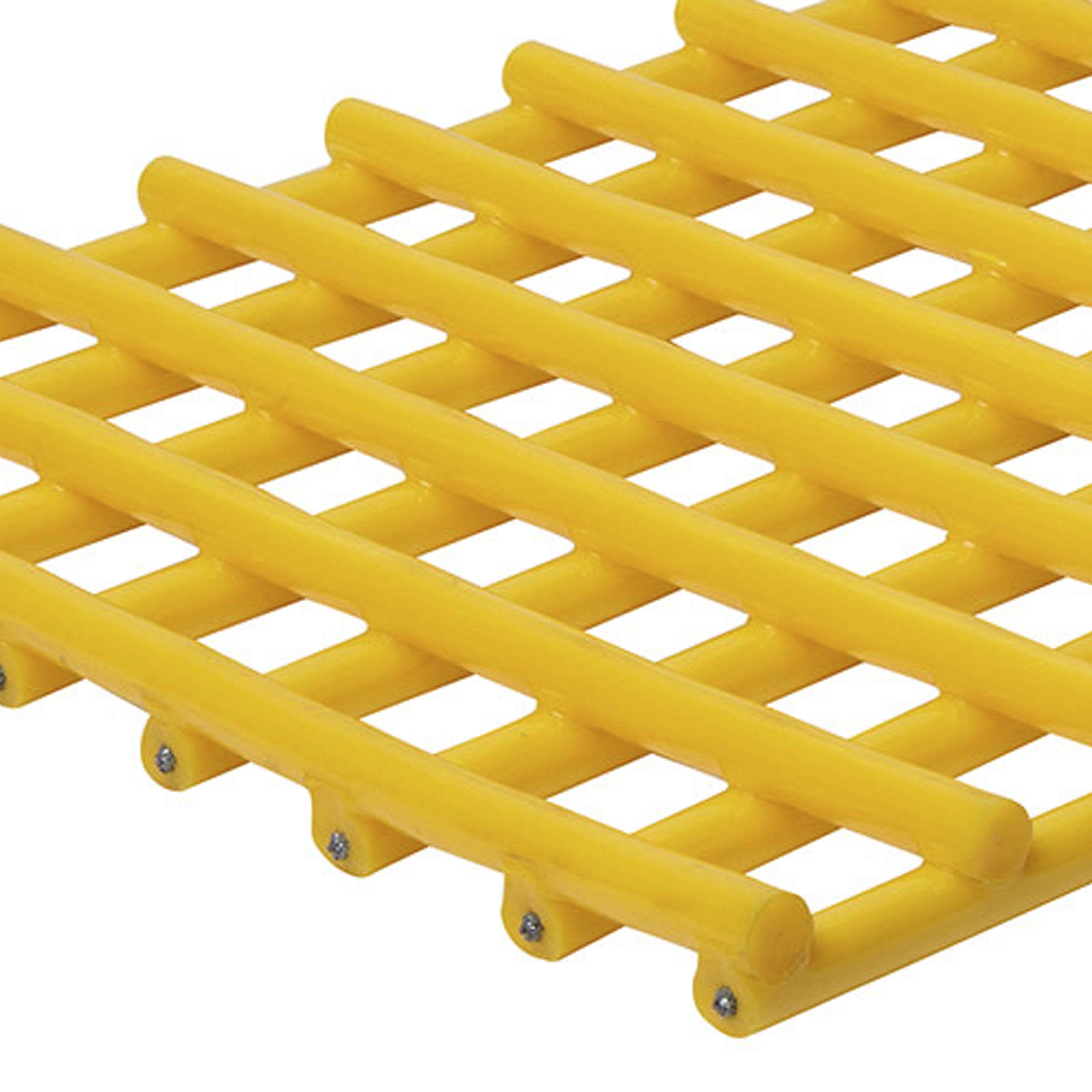

Specialized for Derrick Screen (Stack Sizer), made from high-grade polyurethane.

Self-cleaning, non-blinding screen with enhanced wear life and accurate sizing.

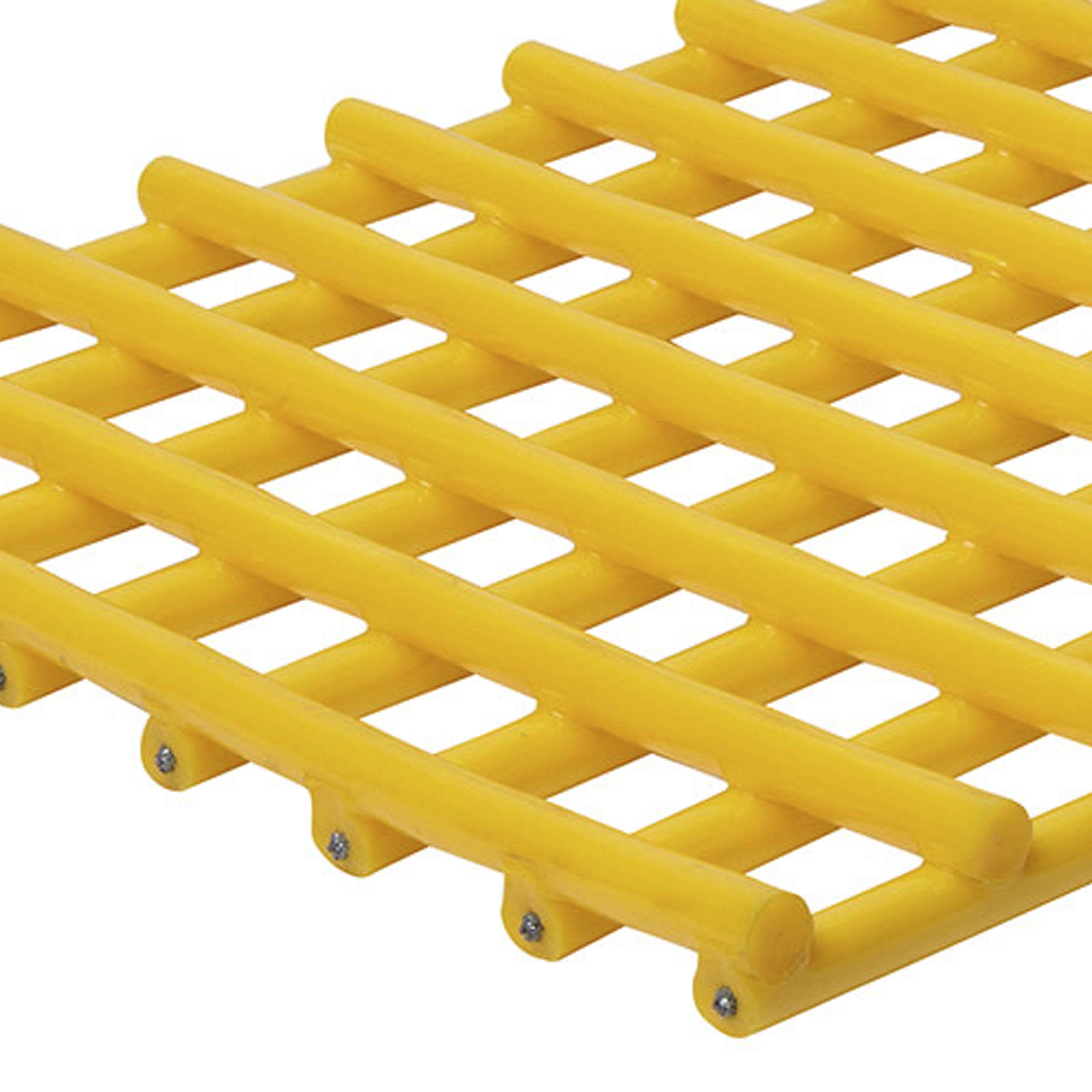

Hybrid poly/wire construction for longer life and reduced noise.

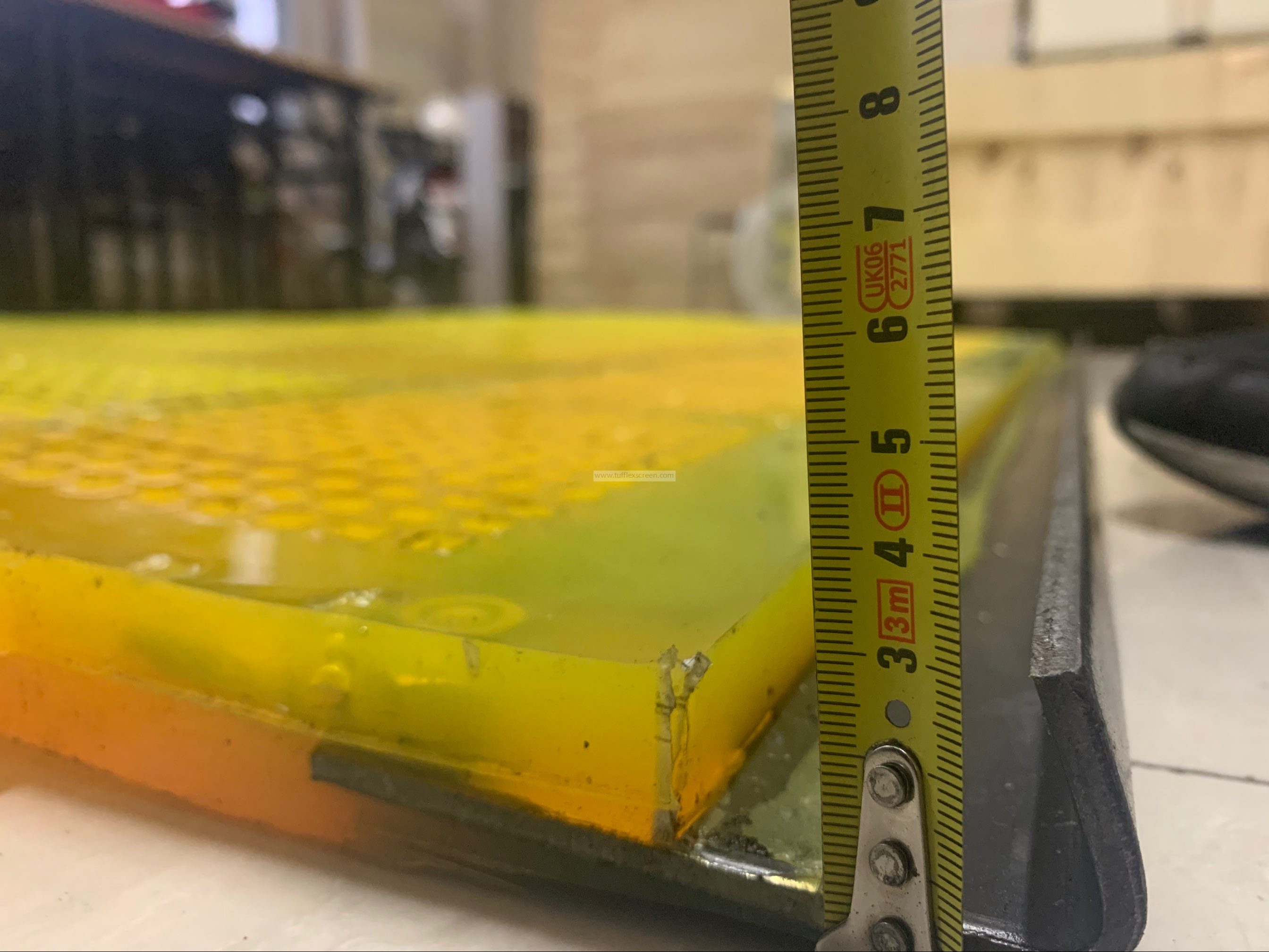

Steel frame with PU surface for high tensile strength and wear resistance.

Efficient for dewatering, desliming, and particle sizing.

Precision-engineered for oil & gas drilling fluid separation.

Dynamic screening surface with oscillating motion to prevent blinding.

High-precision sieving for fine particle separation in mineral processing.

Our advanced screening technology delivers unmatched performance, longevity, and cost-efficiency for industrial applications.

Polyurethane and composite materials last 2–3x longer than traditional wire mesh.

Self-cleaning surfaces prevent blinding and pegging for continuous operation.

Tailored screen sizes, apertures, and materials to match your equipment.

Reliable supply chain and technical support for customers worldwide.

Our screen panels are primarily made from high-quality polyurethane, with some hybrid models combining polyurethane and wire mesh (e.g., Tufflex). We also offer rubber and ceramic wear parts.

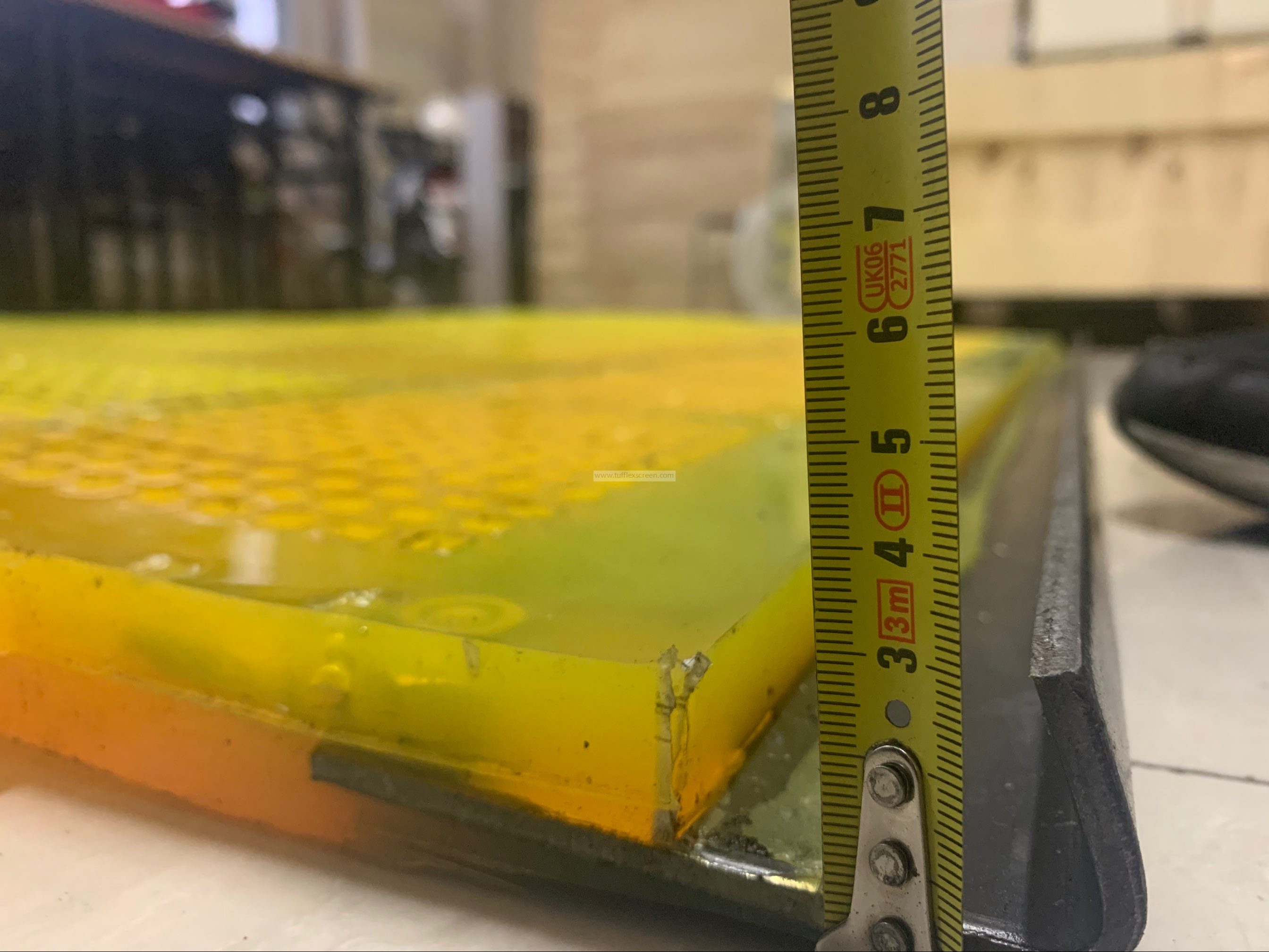

Yes, we offer full customization. Common sizes like TH48-30, TH48-42, and 700x1040mm are standard, but we can design screens to your exact specifications, including apertures from 0.043mm to 45mm.

Typical service life ranges from 6 to 12 months depending on application, material type, and operating conditions. They generally last 2–3 times longer than traditional wire mesh screens.

Yes, we manufacture shale shaker screens compatible with Derrick Stack Sizer and other major brands. Aperture sizes range from 0.045mm to 8.0mm.

You can click the WhatsApp link on any product card to send a direct message, or visit mineralscreen.com to contact the official team.

For product inquiries, technical support, or custom orders, reach out through the official website.

Note: No direct email or phone number found on source page. Please use the official website for communication.

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info