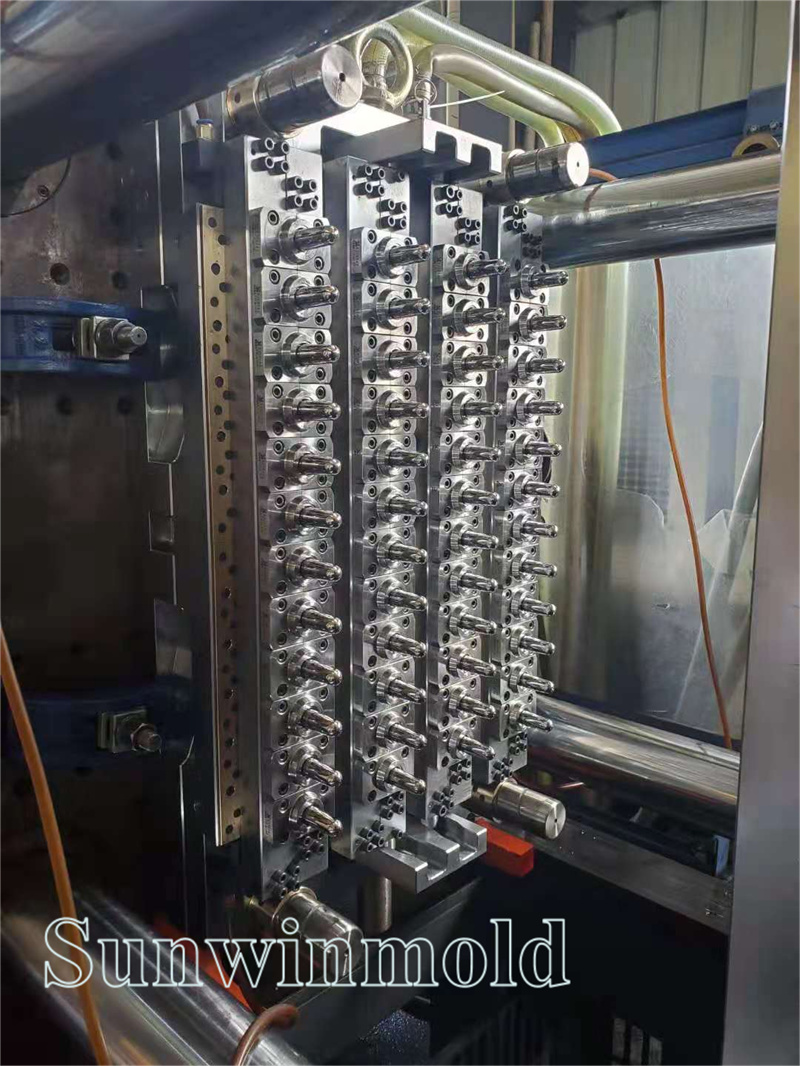

About Sunwin Mould

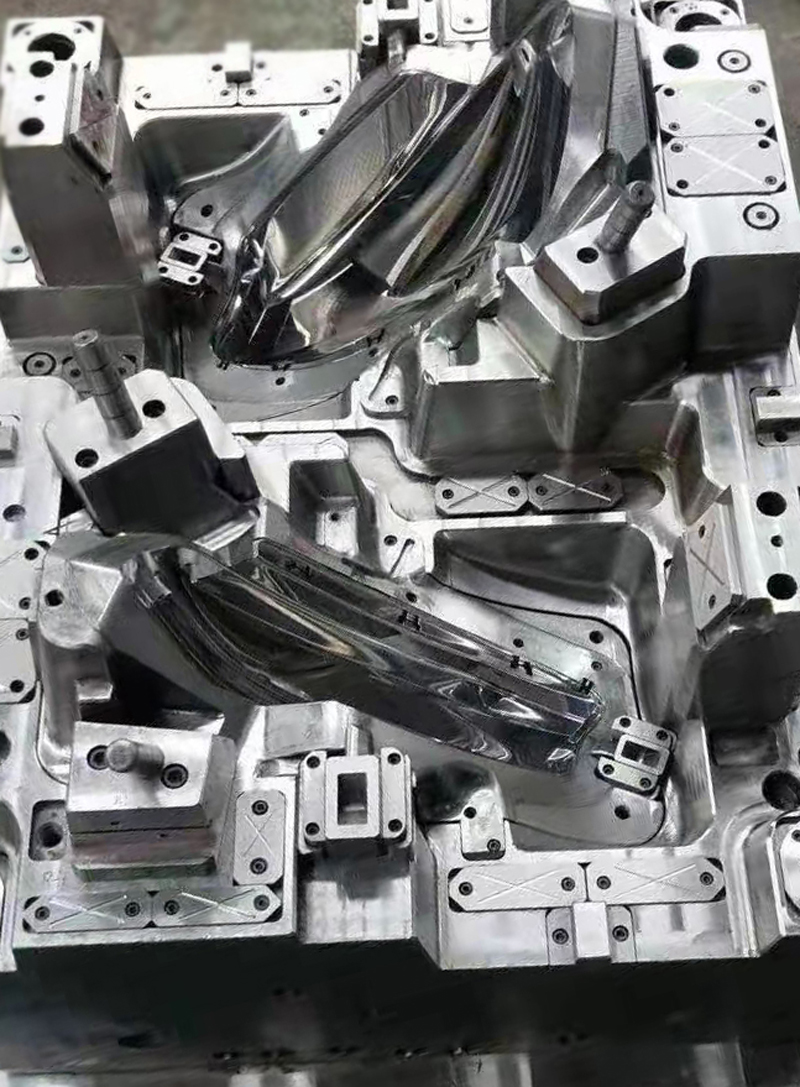

Taizhou Huangyan Sunwin Mould Co., Ltd., located in Huangyan, Zhejiang Province — known as the "City of Plastics and Mold" — has been a leader in precision mold manufacturing since 2010. With over 2,000 square meters of factory space and a team of more than 60 professional engineers and technicians, we specialize in high-precision injection molds for global industries.

Our expertise lies in advanced design using CATIA, AutoCAD, and Moldflow simulation software, ensuring optimal gate design, structural integrity, and cycle efficiency from the earliest stages.