Trusted Engineering Excellence Since 1970

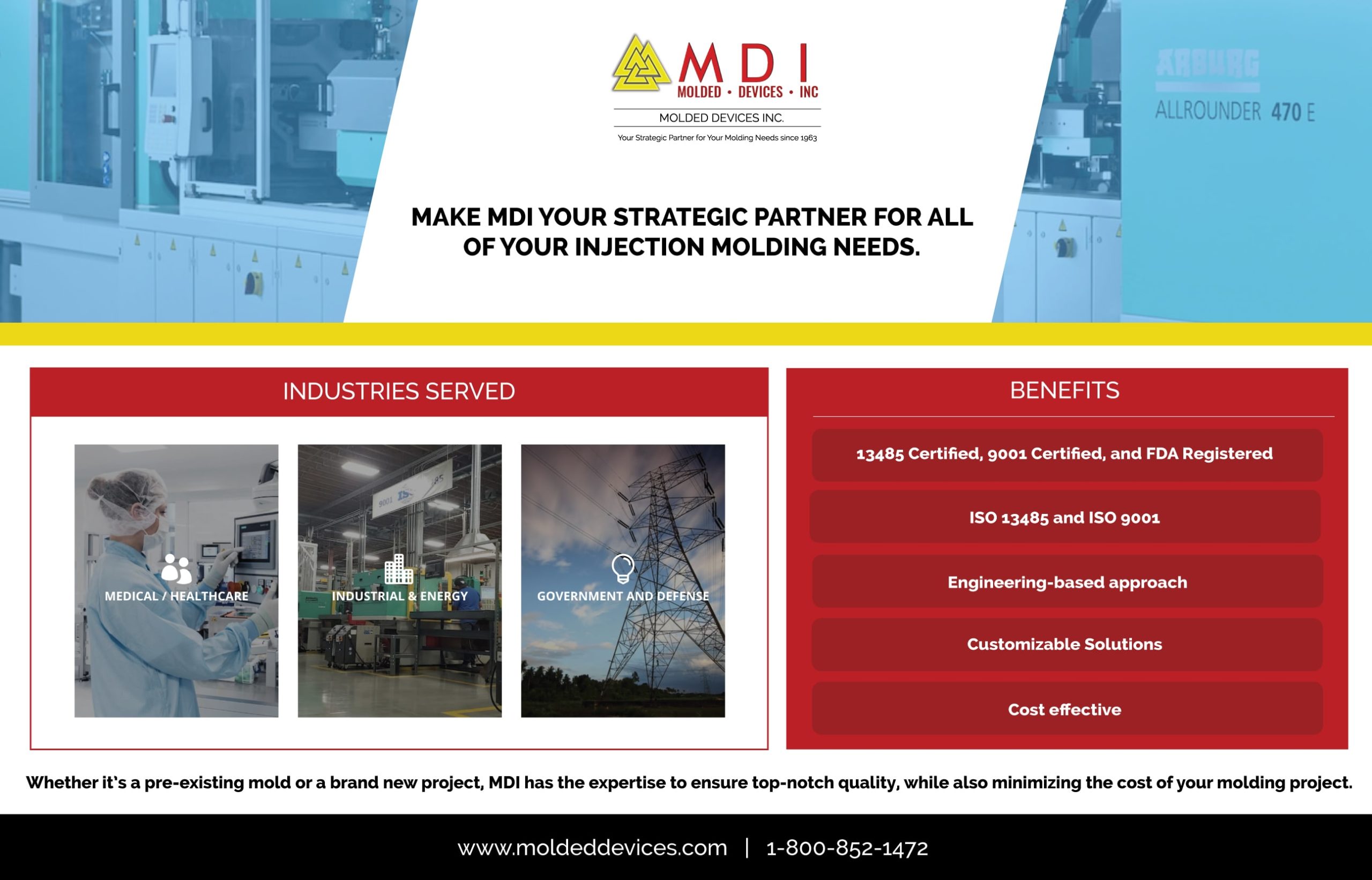

Molded Devices Inc. (MDI) has been a leader in custom plastic molding and contract manufacturing for over five decades. We specialize in solving complex supply chain and production challenges for OEMs across the medical, industrial, and aerospace sectors.

From concept and design to full-scale production and sterile packaging, our world-class engineering team applies innovative techniques to ensure every component meets the highest standards of precision, durability, and compliance.