Global Injection Molds Manufacturer

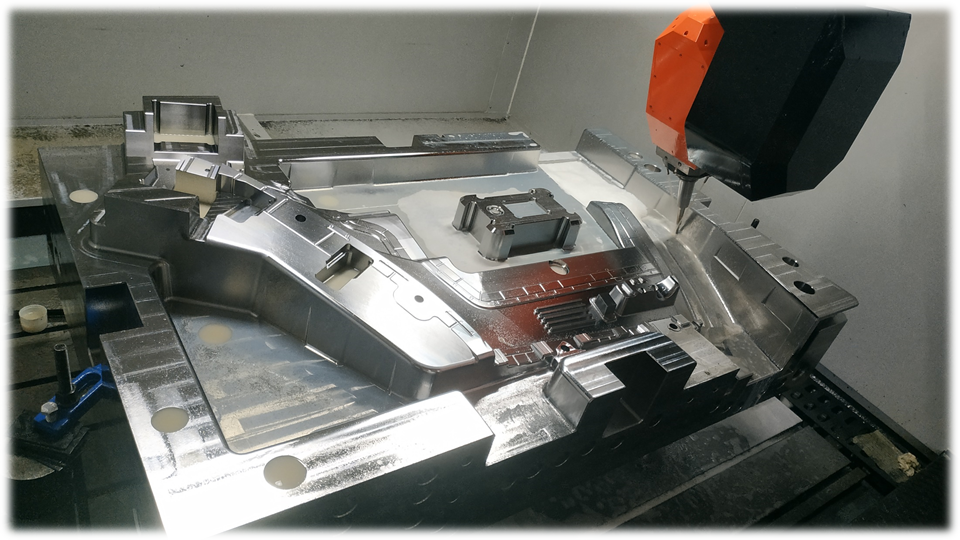

With over 25 years of experience, MoldSN specializes in custom plastic injection molds and CNC processing for automotive, medical, industrial, and consumer applications.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

With over 25 years of experience, MoldSN specializes in custom plastic injection molds and CNC processing for automotive, medical, industrial, and consumer applications.

MoldSN is a professional injection mold manufacturer based in Chang'an Town, Dongguan City, Guangdong Province, China. With over 25 years of industry expertise, we specialize in designing and manufacturing high-quality plastic injection molds for a wide range of applications.

Our workshop is equipped with advanced machinery including 5-axis gantry CNC, high-speed CNC, two-heads EDM, wire-cut, CMM inspection, and press machines ranging from 60 to 3600 tons. We serve clients across America, Europe, Japan, and beyond.

We manufacture a wide range of specialized molds for automotive, medical, electronics, and industrial applications.

Specialized in automotive components including bumpers, dashboards, grilles, door panels, fenders, pillars, and lamp housings.

Capable of producing large-scale molds with precision engineering and structural integrity for industrial and automotive use.

High-tolerance molds for medical, electronics, and industrial applications requiring micron-level accuracy.

Efficient multi-cavity solutions for high-volume production with consistent quality across all cavities.

Advanced hot runner systems for reduced cycle times, material savings, and improved part consistency.

Mirror finish molds for optical clarity and aesthetic surfaces in consumer and medical products.

Dual-shot molds for multi-material or multi-color plastic parts with seamless integration.

Gas-assisted injection for hollow parts with reduced warpage, sink marks, and material usage.

Automated thread molding with core pulling mechanisms for caps, closures, and threaded components.

Double-deck molds that double output per cycle, ideal for high-volume production with space efficiency.

Fast-turnaround prototype molds for design validation and pre-production testing.

Precision overmolding on metal or plastic inserts for enhanced functionality and durability.

From concept to final product, we offer full in-house engineering and manufacturing services.

Our molds and parts are trusted by global clients across diverse sectors.

Bumpers, dashboards, grilles, door panels, fenders, pillars, lamp housings.

Appliances, containers, furniture components, kitchenware, storage.

Diagnostic devices, housings, surgical tools, lab equipment, enclosures.

Machine parts, housings, connectors, gears, structural components.

Enclosures, connectors, buttons, heat sinks, 3C digital parts.

Equipment housings, protective gear, fitness devices, accessories.

Toys, feeders, carriers, grooming tools, training devices.

Action figures, building blocks, vehicles, educational toys, playsets.

We specialize in vehicle molds (bumpers, dashboards, grilles), large size molds, precision molds, hot runner molds, 2-color molds, gas assist molds, stack molds, and rapid prototype molds.

We serve automotive, medical, electronics (3C), household appliances, industrial, sports, pet, and toy industries.

Our injection press machines range from 60 to 3600 tons. We have a 3-meter CNC, 5-axis drilling, two-heads EDM, and CMM inspection for quality control.

Yes, we are ISO 9001:2008 certified, ensuring consistent quality and process control in all our manufacturing operations.

Our factory is located in Building A12, Haibin Road 20, WuSha, ChangAn, DongGuan, GuangDong, China.

Get in touch for mold design consultation, quotes, or technical support.

+86-13670237035

13670237035

Andy@moldsn.com

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info