Engineered for Excellence

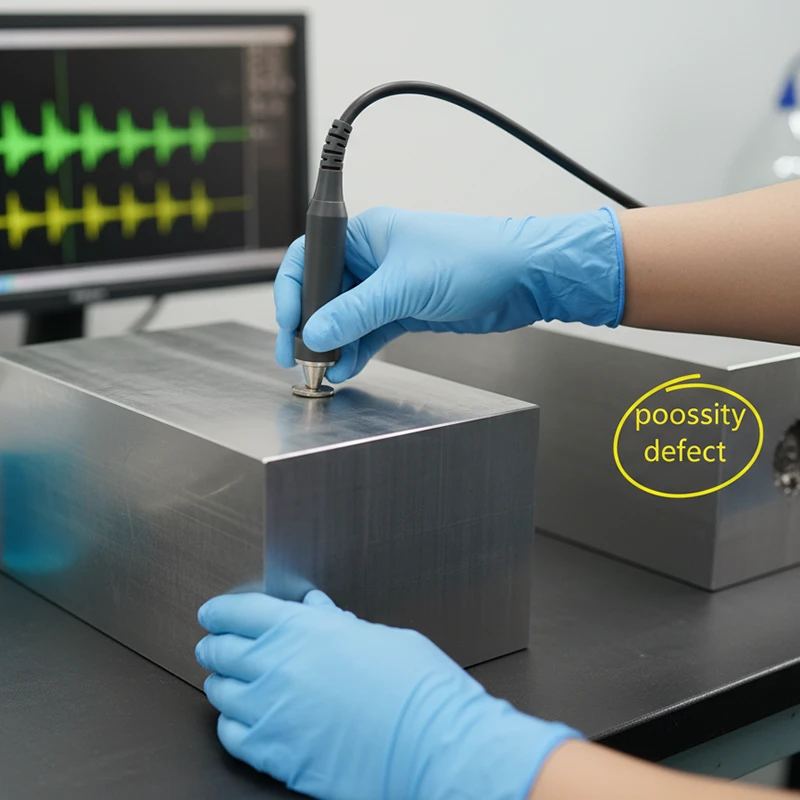

Moldsteells is a leading manufacturer and supplier of high-precision mold steel materials, serving industries ranging from automotive and electronics to medical devices and consumer goods. With decades of experience, we specialize in delivering consistent, high-quality steel tailored to your exact specifications.

Our commitment to innovation and quality control ensures every product meets international standards. Whether you need standard grades or custom solutions, we provide reliable materials that enhance mold longevity, surface finish, and production efficiency.

- ISO-Certified Manufacturing

- 100% Ultrasonic Testing Available

- Custom Cutting & Machining

- Global Shipping & Support