About MSK Cutting Tools

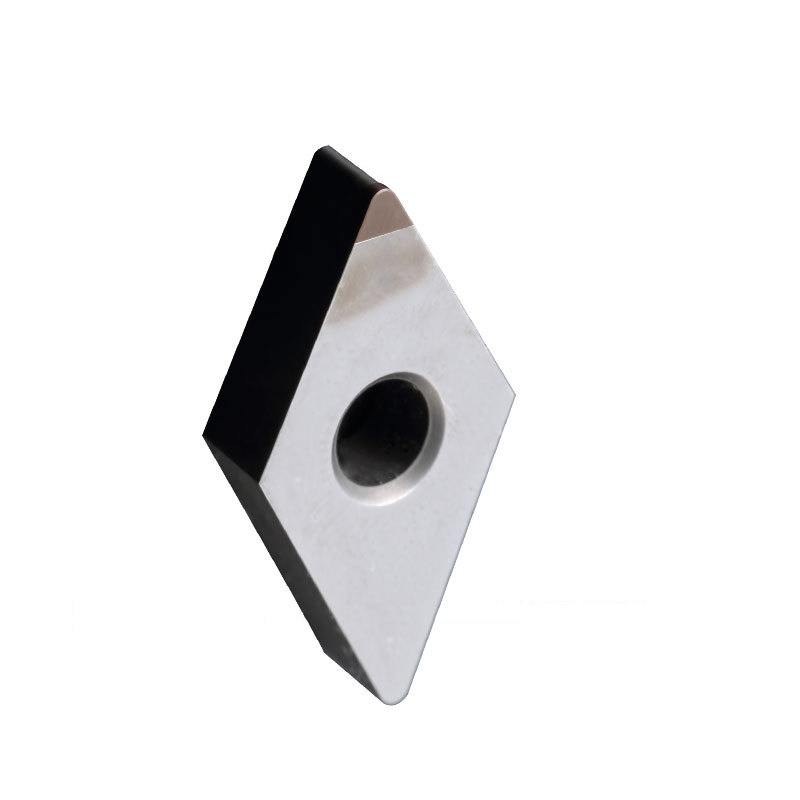

Established in 2015, MSK (Tianjin) International Trading Co., Ltd. is a leading manufacturer of high-precision CNC cutting tools based in Tianjin, China. We specialize in MCD (Monocrystalline Diamond), PCD (Polycrystalline Diamond), and CVD/PVD diamond tools for jewelry, watchmaking, and industrial applications.

Equipped with 6 SACCKE high-end five-axis grinding centers, a German ZOLLER six-axis tool inspection system, and advanced machinery from Taiwan PALMARY, we ensure every tool meets the highest standards of precision and performance.

Since 2016, MSK has provided technical support and custom tooling solutions to over 20 factories globally, earning a reputation for quality, reliability, and innovation.