Why Multiplastics?

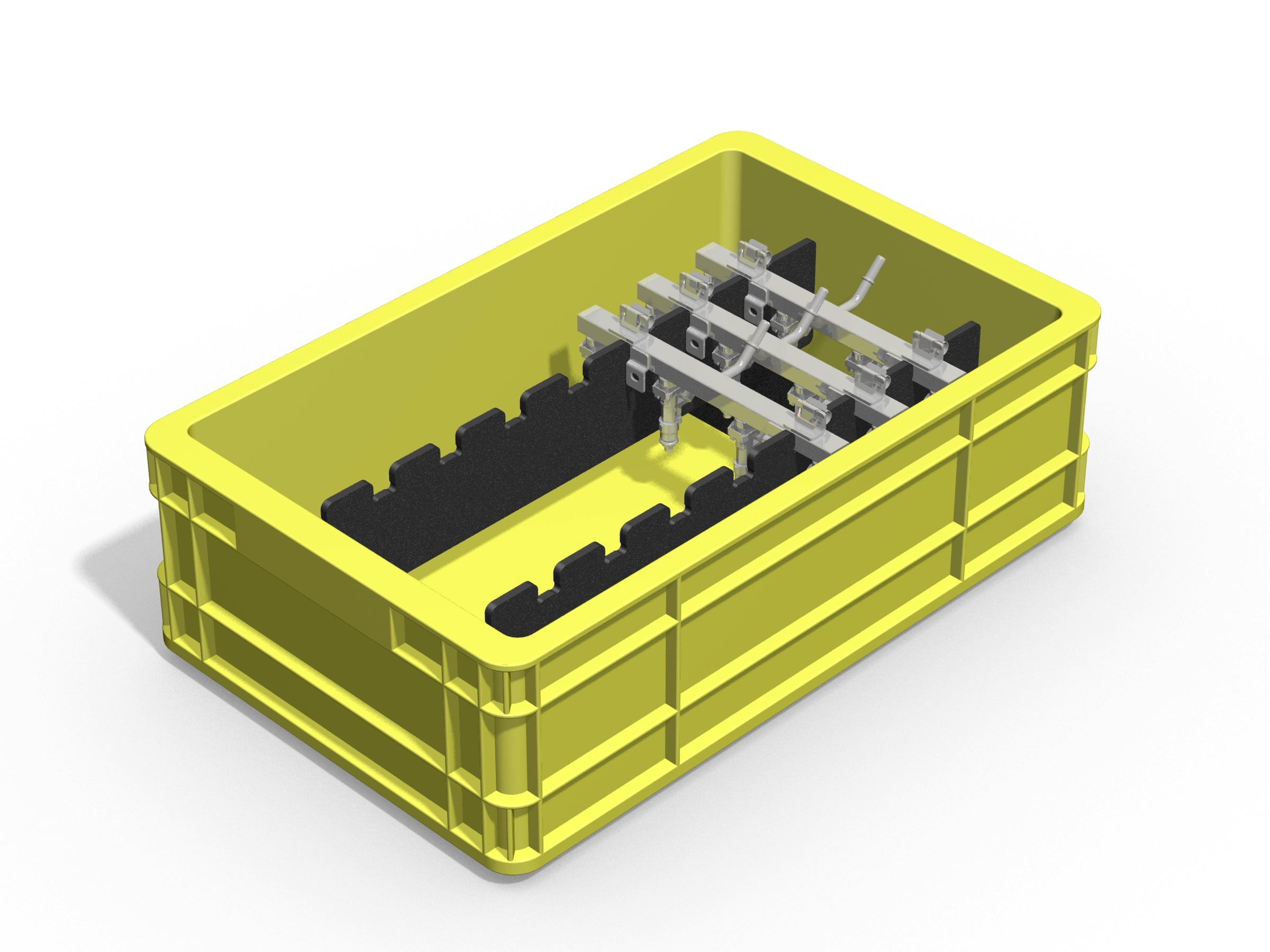

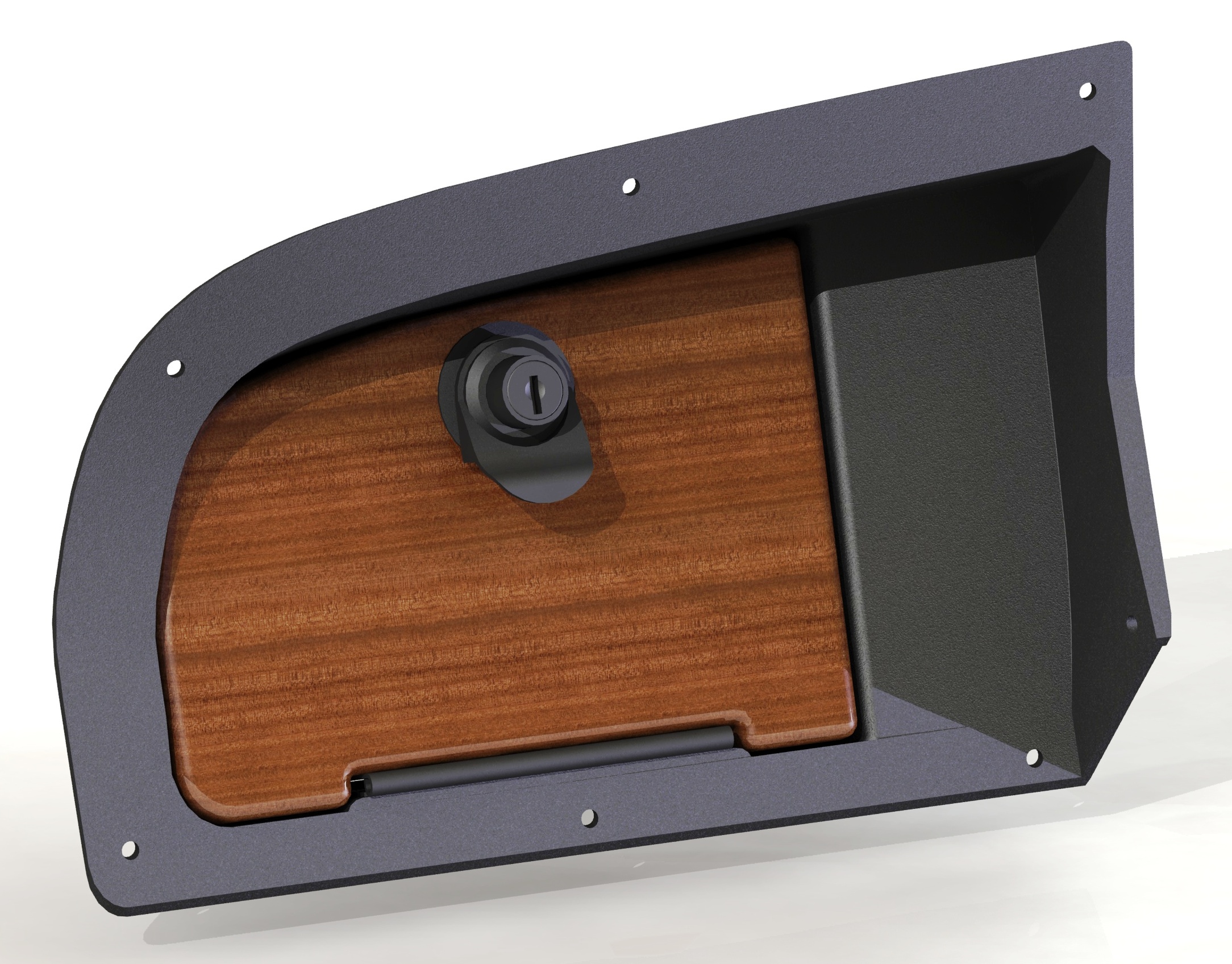

Since 1952, Multiplastics has been a pioneer in custom plastic manufacturing, combining engineering precision with creative problem-solving. As the leading plastics manufacturer in the Southeast, we serve industries ranging from aerospace to medical, delivering high-quality, innovative solutions from concept to production.

Our team of experienced engineers and technicians specialize in advanced techniques like thermoforming, injection molding, and rapid tooling design. We don’t just build parts—we build partnerships.

70+

Years of Experience

1000+

Projects Delivered

15+

Industries Served