About Nanyan Technology

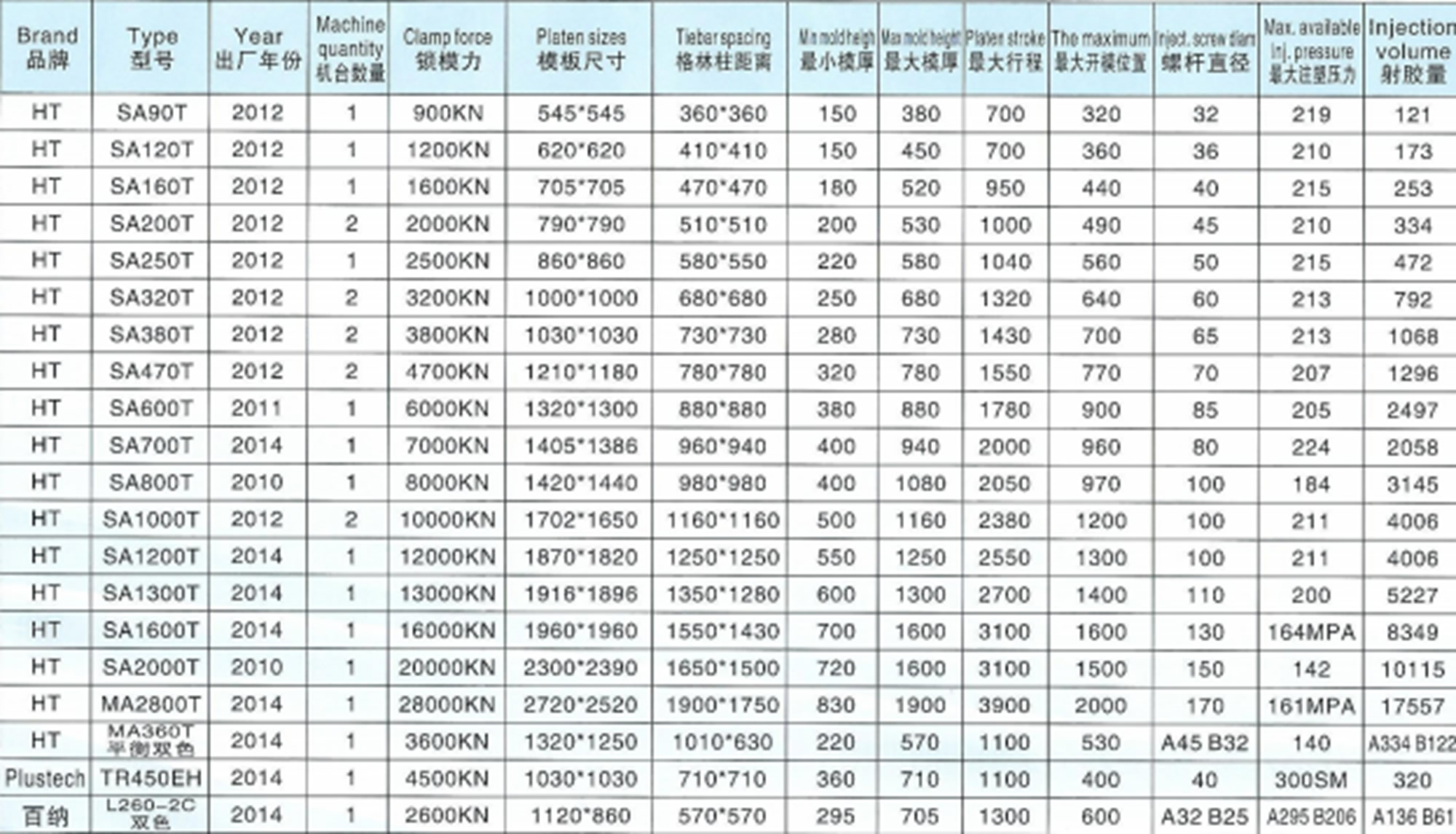

Dongguan Nanyan Injection Molding Co., Ltd. is located in the mold manufacturing capital of China — Dongguan Chang’an. We provide comprehensive services including new product development and design, precision mold design and manufacturing, injection molding processing, half-finished/finished product assembly, and post-process treatments.

Our strategic location offers excellent accessibility — less than 10 minutes from the Guangzhou-Shenzhen Expressway Chang’an exit, across the river from Shenzhen, and adjacent to Guangzhou, Huizhou, and Zhongshan.