About OUHONG SEALING

OUHONG is a modern enterprise specializing in the production of high-precision valve components. With a comprehensive product line including seals, seats, and valve balls, we serve a wide range of industries requiring reliable performance under extreme pressure, temperature, and corrosive environments.

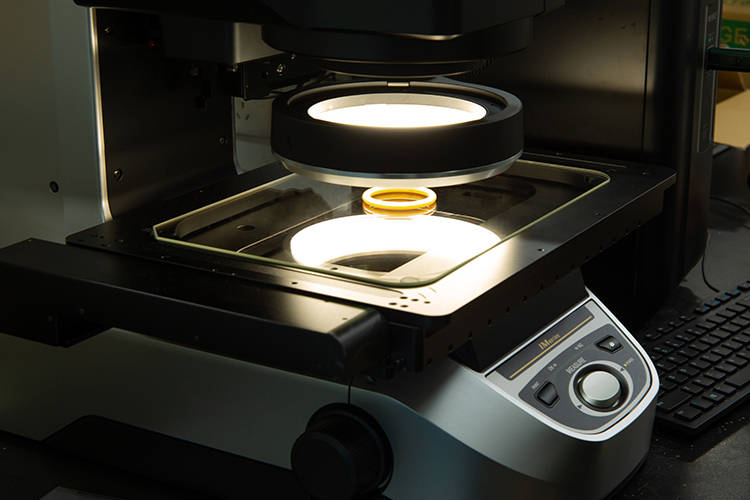

Our commitment to quality is reflected in our advanced production and testing equipment, scientific field management, and strict process control. Every product is manufactured to meet international standards and tailored to specific customer requirements.

R&D Excellence

OUHONG operates a fully equipped R&D center with professional teams in each factory. We collaborate with local universities to maintain cutting-edge innovation and testing capabilities.

Quality Assurance

Scientific site management and strict quality control ensure every component meets the highest standards. We are committed to ISO-level consistency and reliability.

Global Applications

Our products are widely used across oil & gas, petrochemical, power generation, and marine industries, providing sealing solutions in the most challenging environments.