About Panglei Foundry

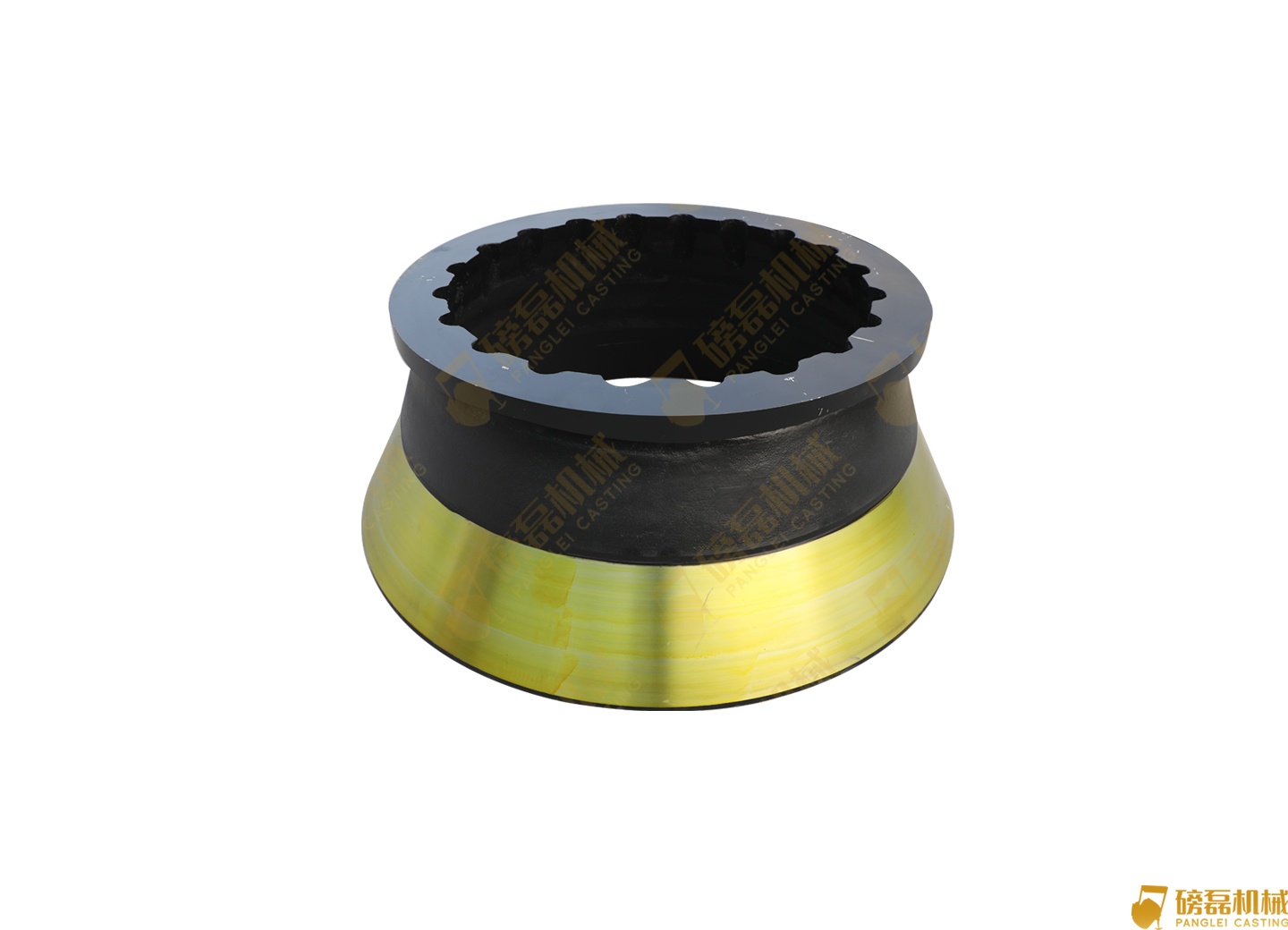

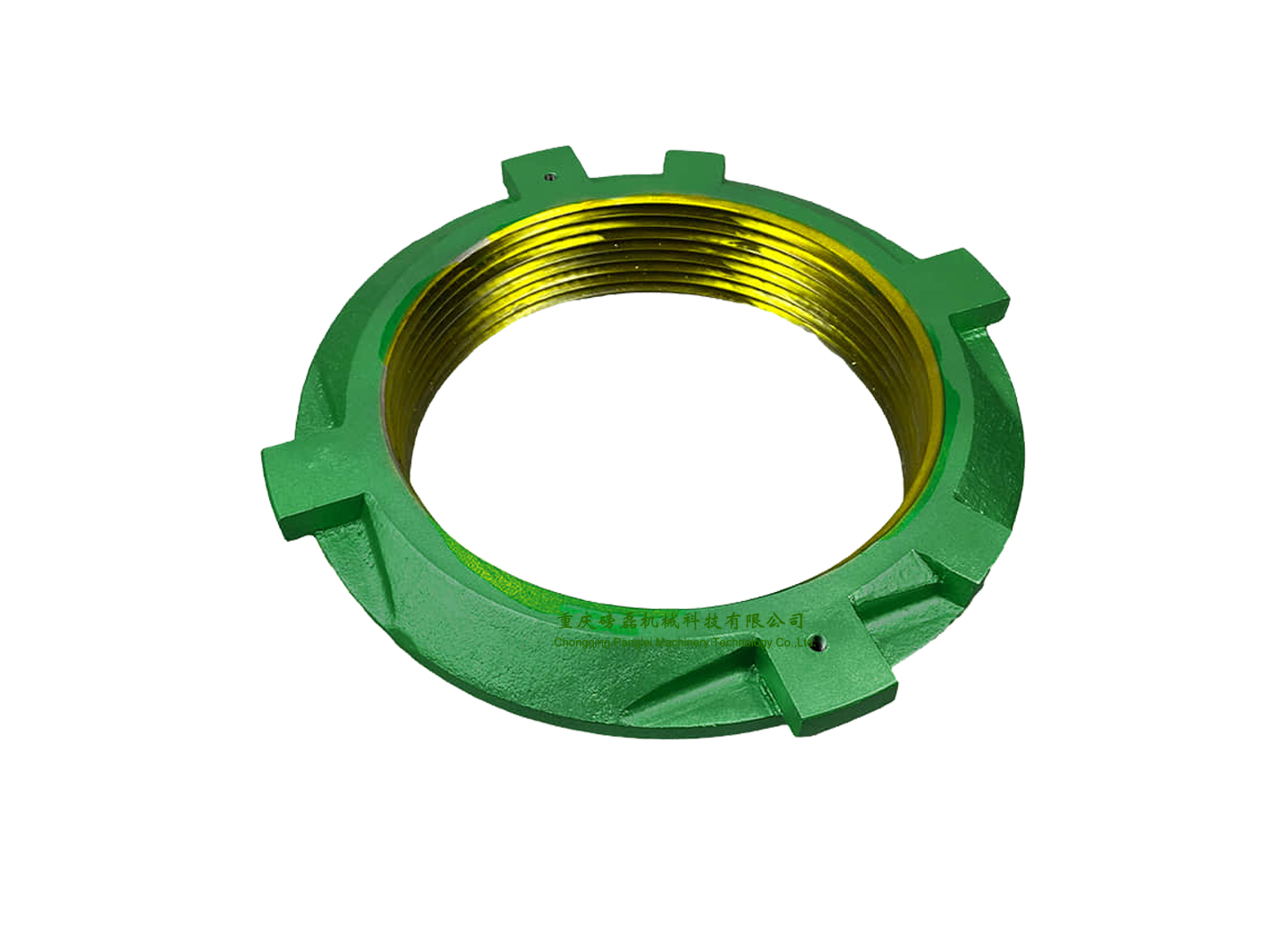

Chongqing Panglei Machinery Technology Co., Ltd. is an ISO-certified foundry specializing in high-performance wear-resistant castings for industrial crushing, grinding, and shredding equipment. With decades of expertise, we deliver premium OEM-equivalent parts trusted by customers worldwide.

Our commitment to quality begins with high-standard raw material sourcing and continues through every stage of production — from pattern-making and casting to heat treatment and precision machining.

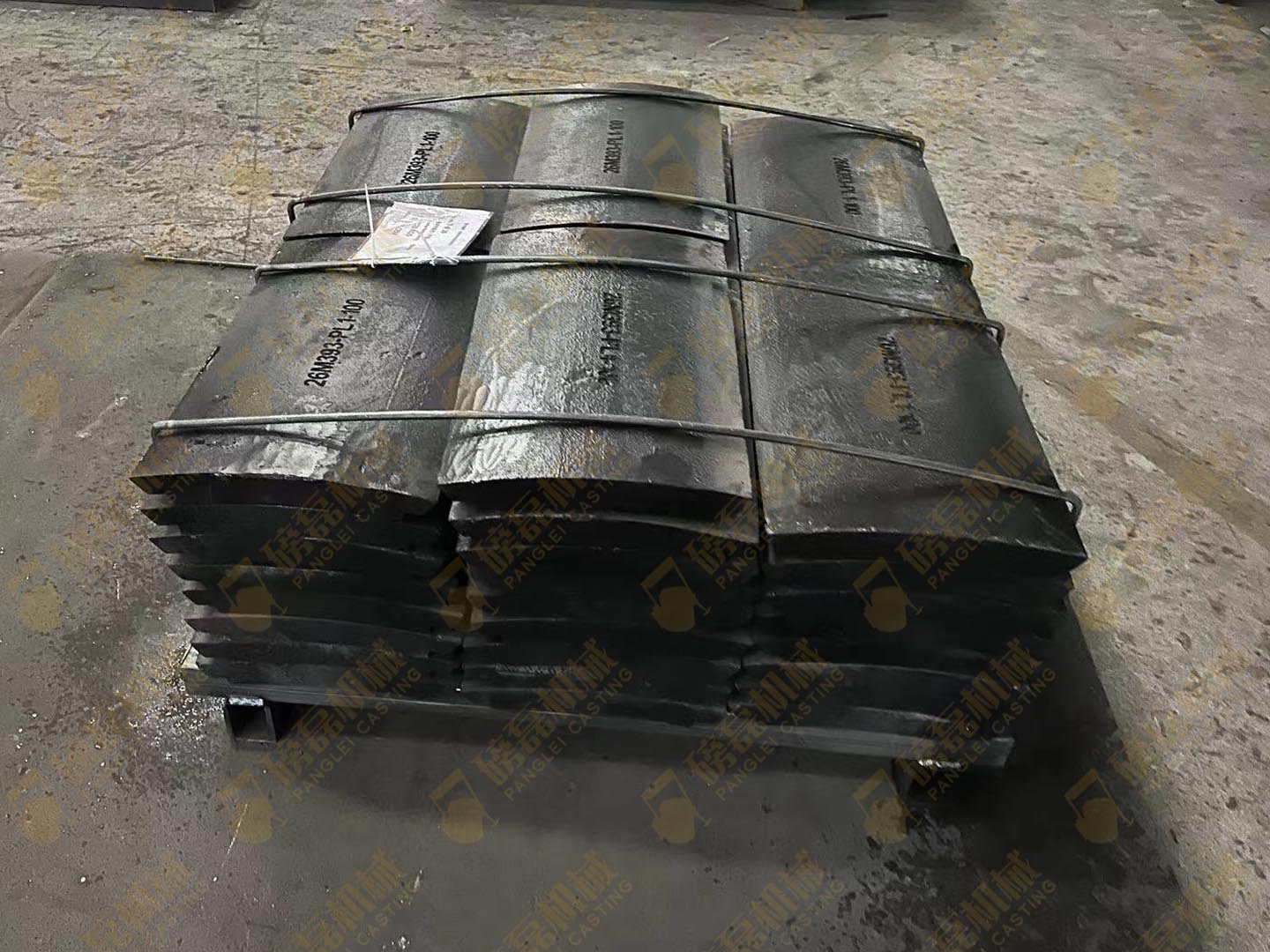

- Thousands of ready-made patterns in inventory

- Shortened lead times & reduced costs

- International packaging & door-to-door delivery