About Topper Plastic Mold

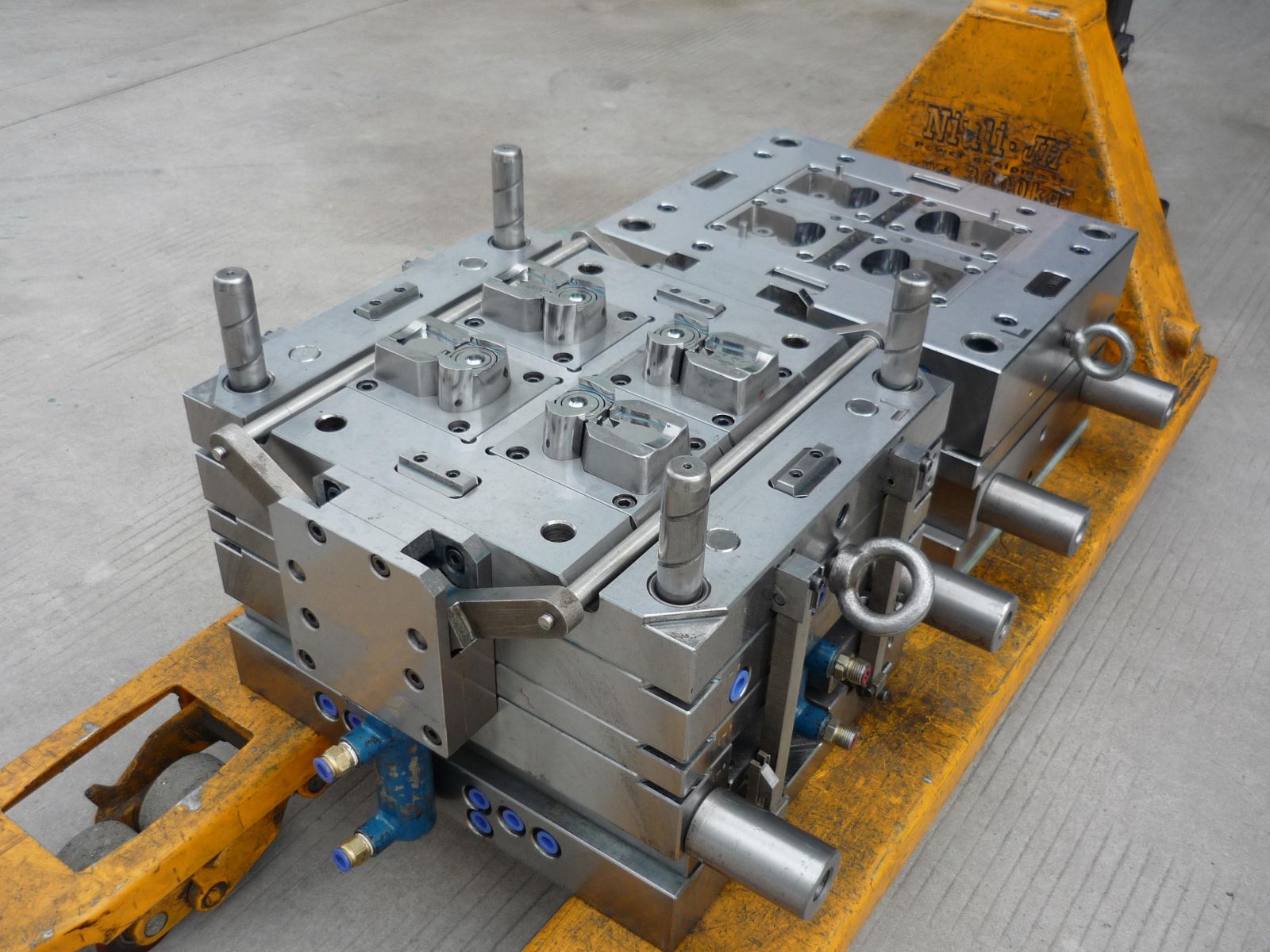

Topper Plastic Mold Co., Ltd. has been a trusted name in the plastic mold industry since 1997. With our own plastic mold foundry and injection molding plant, we offer end-to-end solutions from mold design to mass production.

Our expertise spans across industries including automotive, medical, lighting, and consumer electronics. We specialize in precision plastic injection molds, overmolding, rapid prototyping, CNC machining, and die casting.

- ISO 9001:2008 Certified

- In-house mold design & manufacturing

- German-grade steel molds (718, S136, P20, NAK)

- Molds built to HASCO, DME, LKM, DIN standards