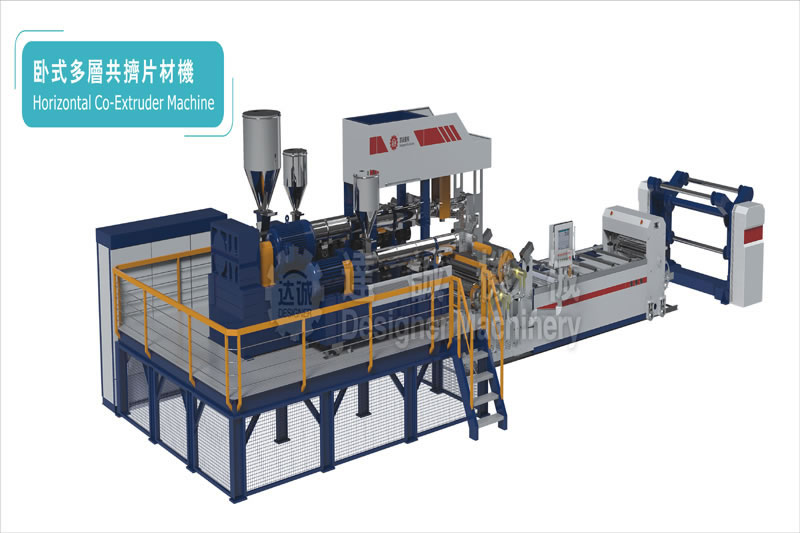

About Lanteky® Machine

Lanteky® Machine is a national high-tech enterprise based in Shantou, China, specializing in the research, development, design, manufacturing, marketing, and service of advanced plastic machinery. Established in 1993, we have grown into a leading manufacturer with over 40,000 m² of workshop space across 5 facilities and more than 200 dedicated professionals, including 50+ senior technical engineers.

We are currently expanding with a new plant exceeding 70,000 m², reinforcing our commitment to innovation and large-scale production. Our mission is to deliver energy-efficient, reliable, and cutting-edge solutions for the global plastic processing industry.

- Energy-saving extrusion technology

- Full automation & intelligent control

- Biodegradable & eco-friendly solutions

- Exported to 80+ countries