Your Professional & Reliable Partner in Advanced Ceramics

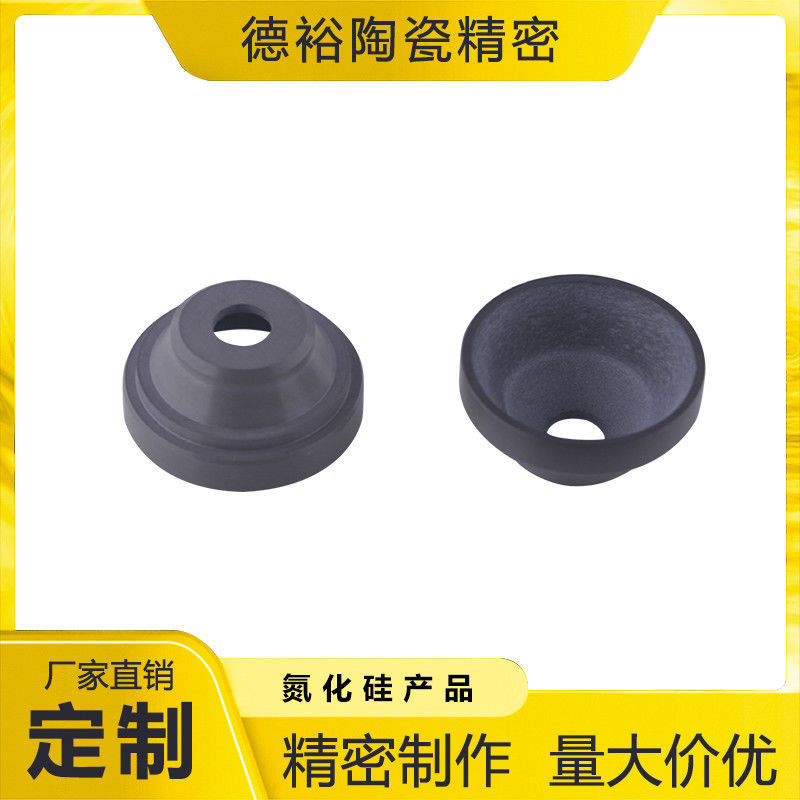

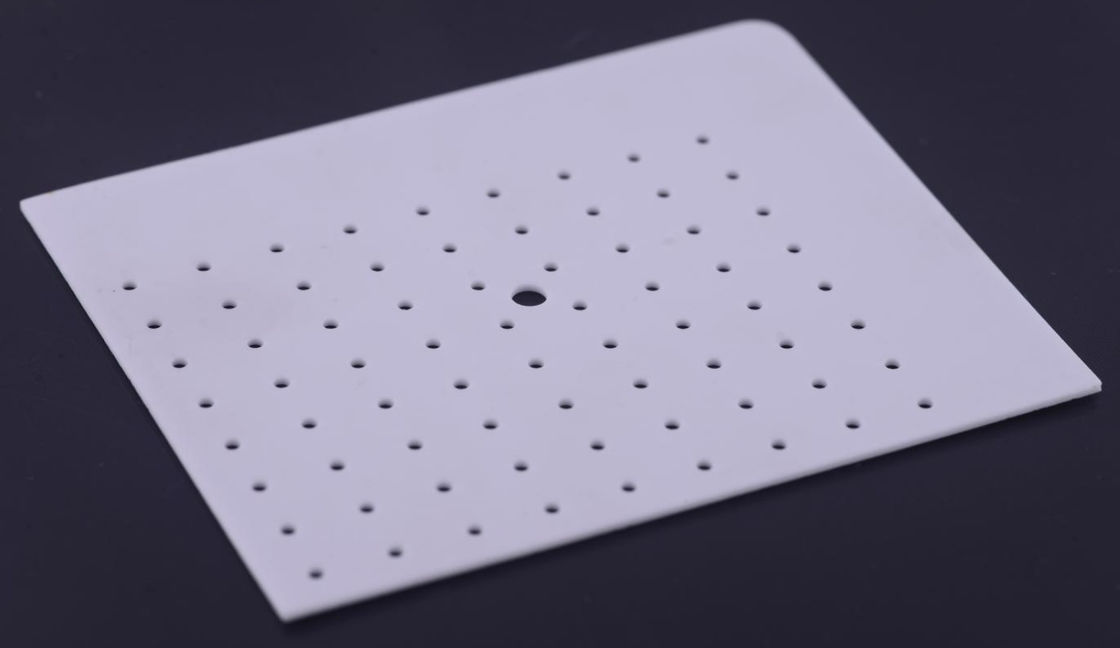

Dayoo Advanced Ceramic Co., Ltd. is a leading manufacturer with years of expertise in designing, producing, and delivering high-precision structural and functional ceramic components. We specialize in advanced materials including zirconia, alumina, silicon nitride, and silicon carbide ceramics.

Our mission is to provide durable, high-performance ceramic solutions that meet the most stringent industrial standards. From concept to production, we ensure full-process precision control — from raw material selection to final inspection.

92–99%

Alumina Purity Range

1600–1800°C

Max Operating Temp