About PRMould

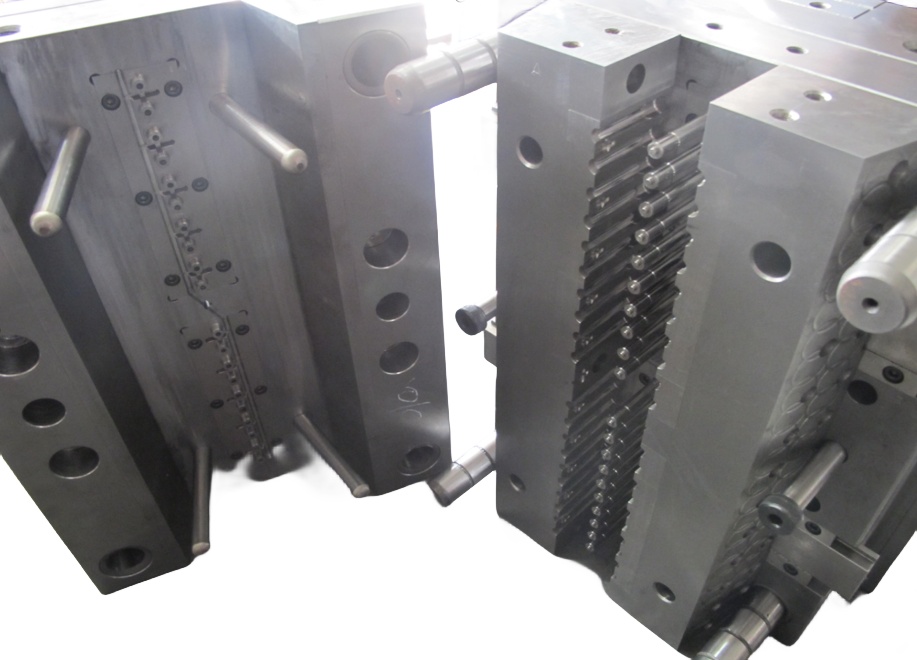

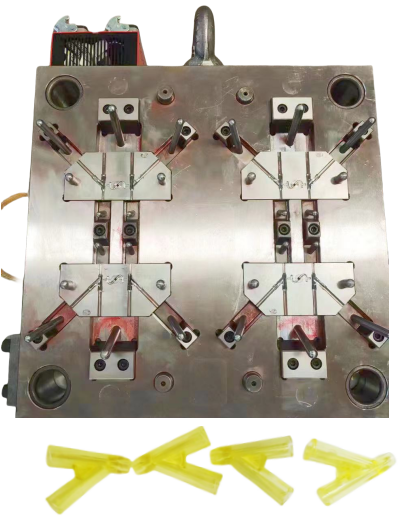

Qingdao Support Demand International Trading Co., Ltd. operates as PRMould — a trusted private consultant in precision mold, tooling, and die manufacturing. With years of engineering excellence, we specialize in turning innovative product concepts into high-quality, production-ready components.

Our expertise spans across multiple industries including automotive, medical devices, cosmetics, and consumer electronics. We combine advanced CNC machining, injection molding, and stamping technologies with rigorous quality control to deliver molds and parts that meet international standards.

- ISO-Compliant Manufacturing Processes

- End-to-End Project Management

- Rapid Prototyping & Tooling

- Global Logistics & After-Sales Support