About JSD Machinery

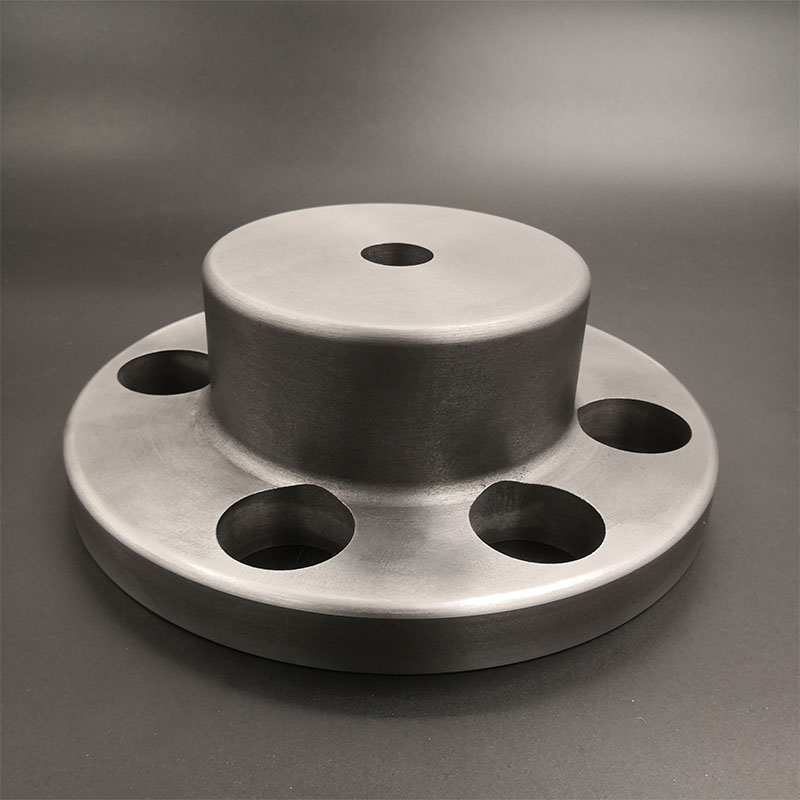

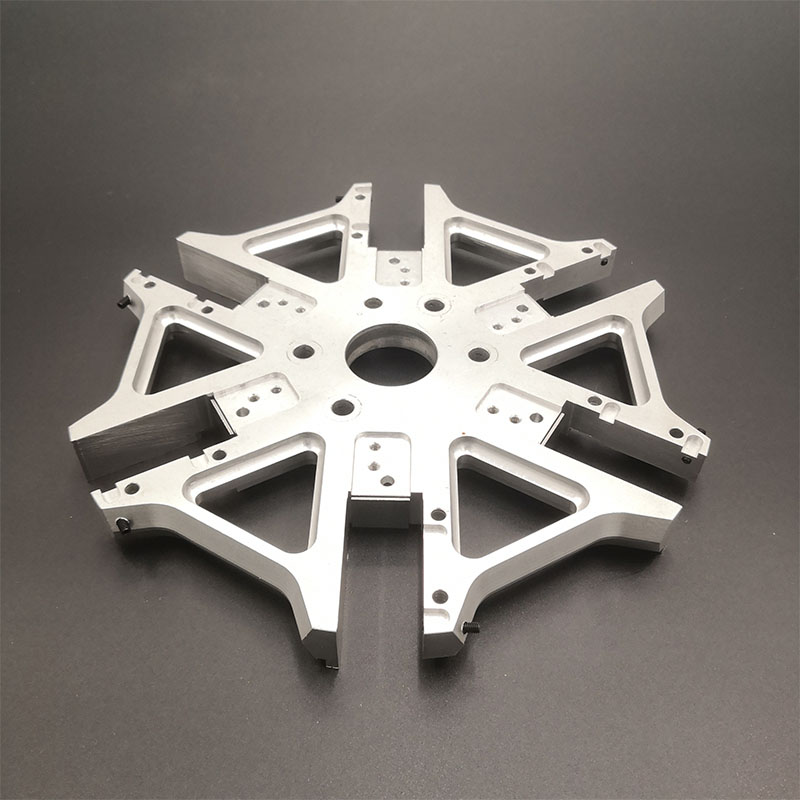

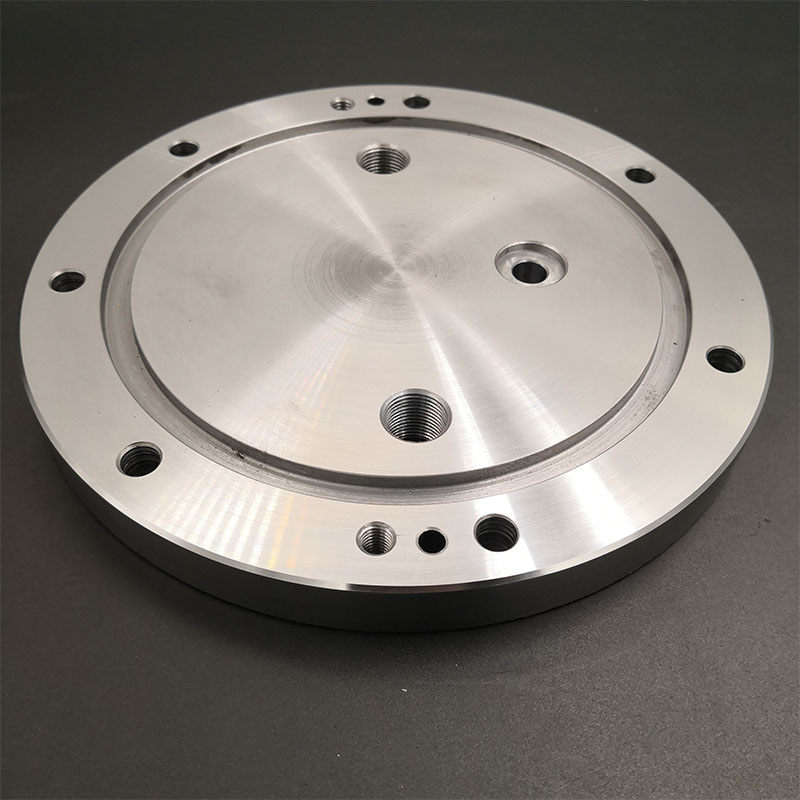

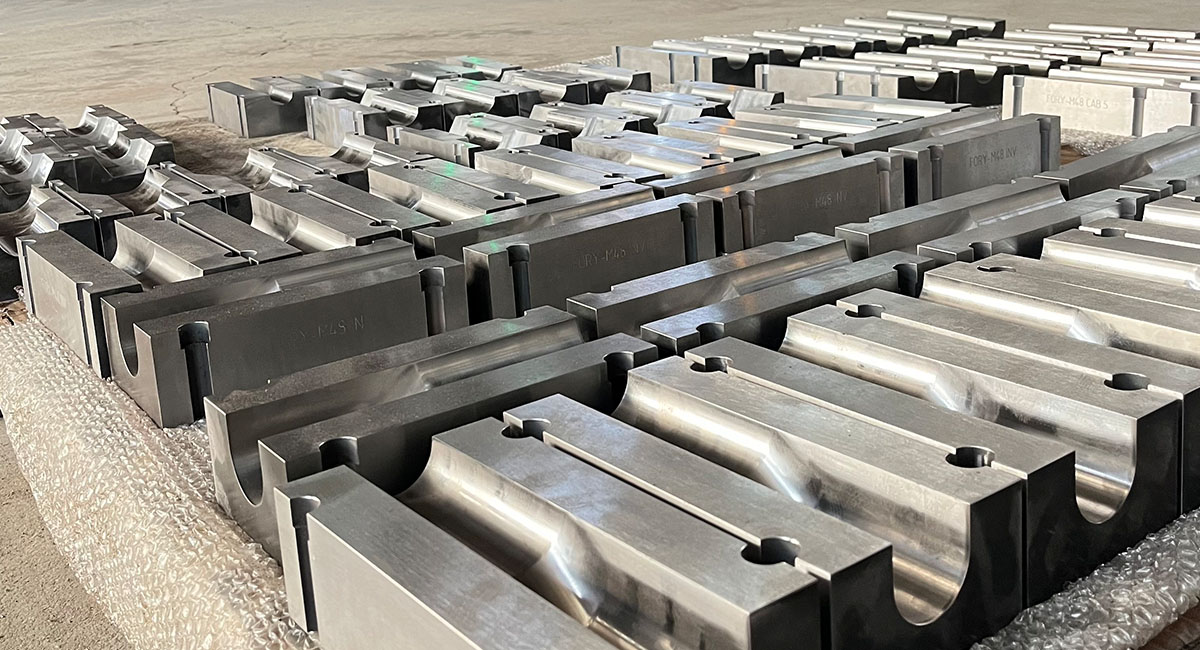

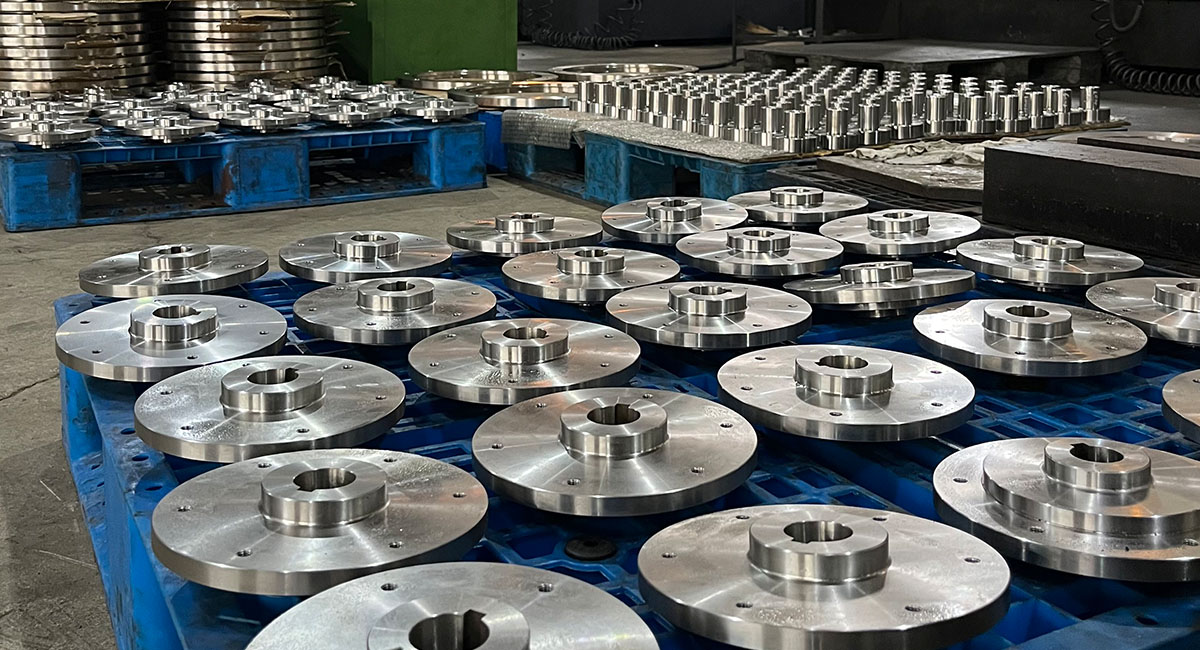

We are a production-oriented enterprise from Qingdao, China, specializing in die casting, forging, precision stamping, sheet metal processing, laser cutting, bending, welding, and precision mechanical processing.

With a high-level technical team and advanced processing equipment, we deliver high-quality industrial components at competitive prices. TIME IS GOLD — and we respect yours with fast turnaround and reliable service.

Choose us for a one-stop purchasing method that simplifies your supply chain and ensures consistent quality across all your industrial part needs.