About Taihong

Qingzhou Taihong Special Casting Steel Co., Ltd. is a leading manufacturer of high-quality grinding media and wear-resistant parts with over 40 years of experience in the industry.

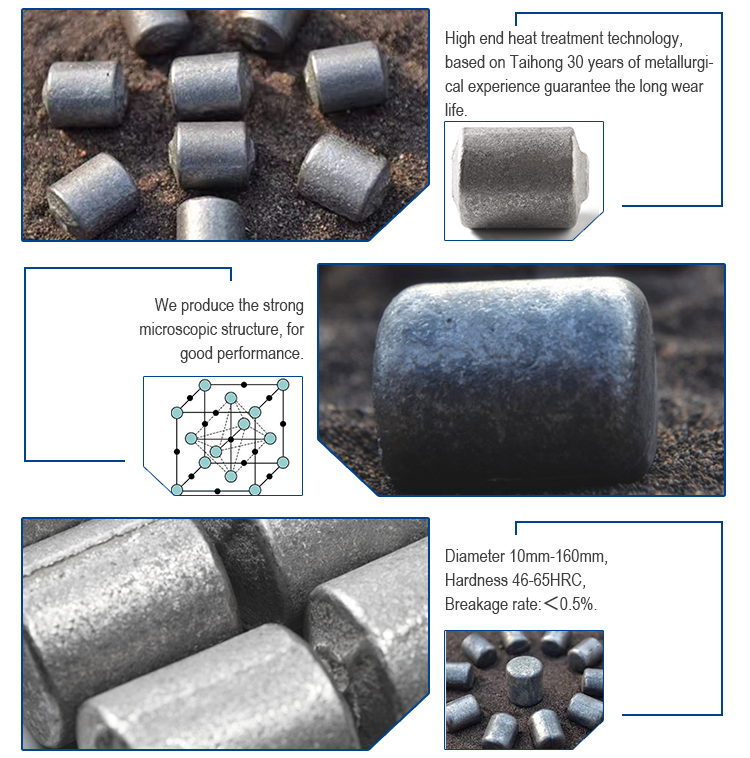

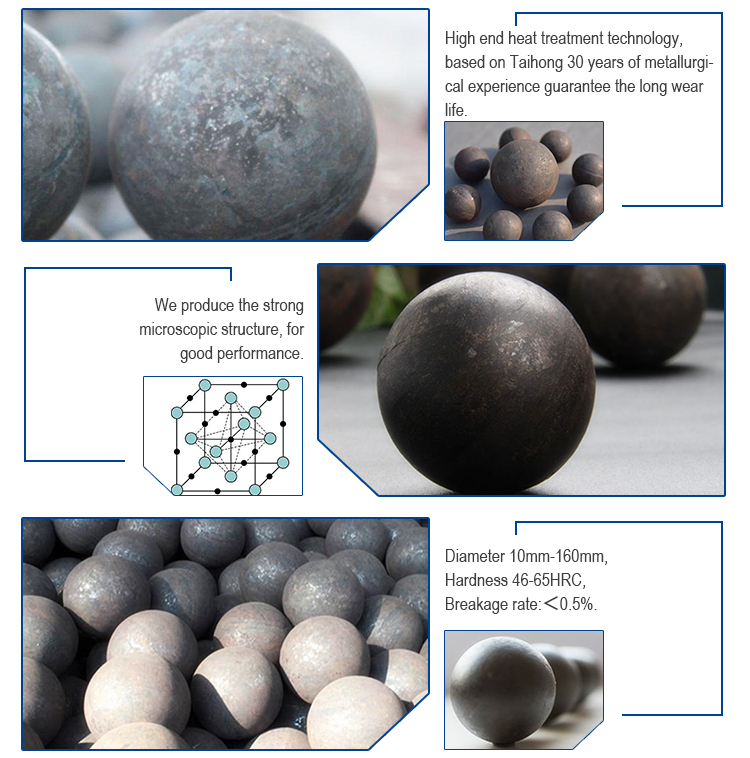

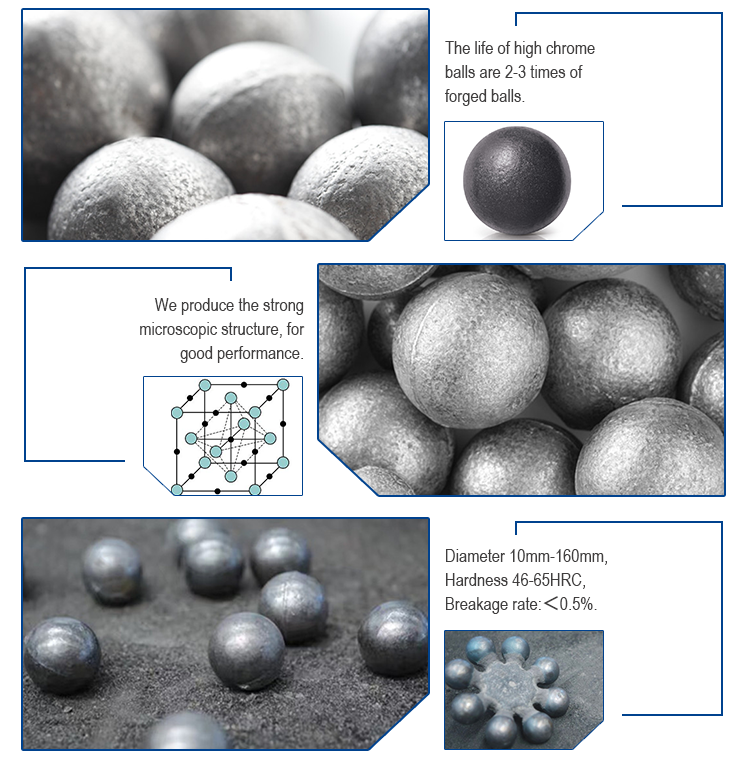

We specialize in producing forged grinding balls, casting grinding balls, grinding cylpebs, steel grinding rods, and mill liners used in mining, cement, and power generation industries.

Our products are exported to more than 90 countries and have earned a reputation for durability, consistency, and performance under extreme conditions.

- 40+ Years of Industry Experience

- ISO-Certified Manufacturing

- Global Distribution Network

- R&D-Driven Quality Control