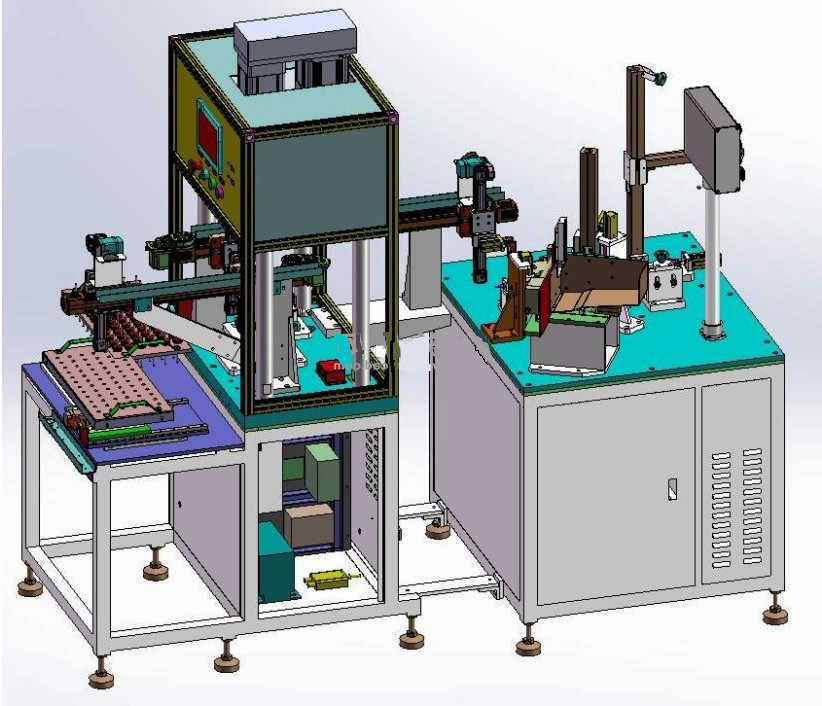

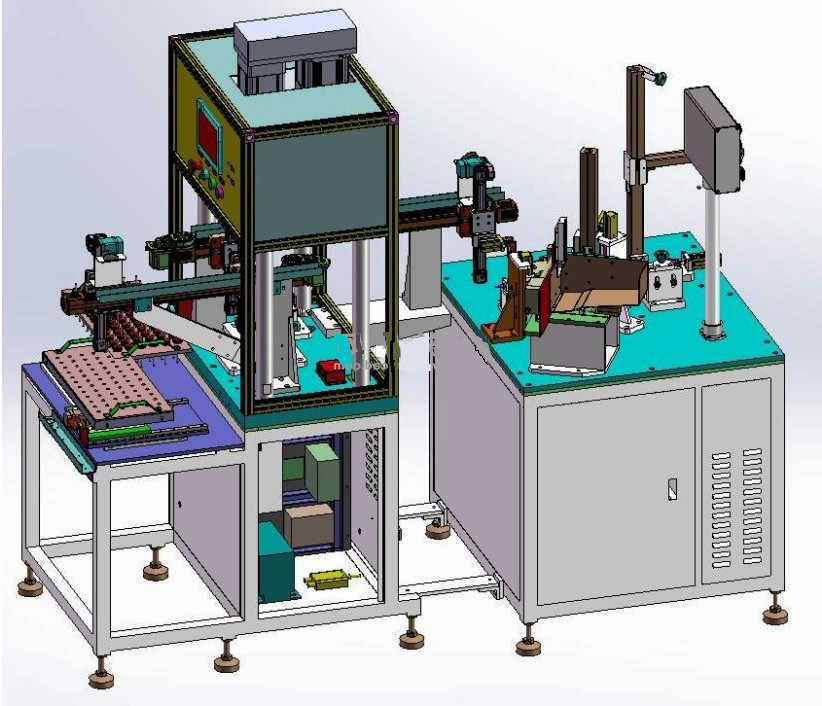

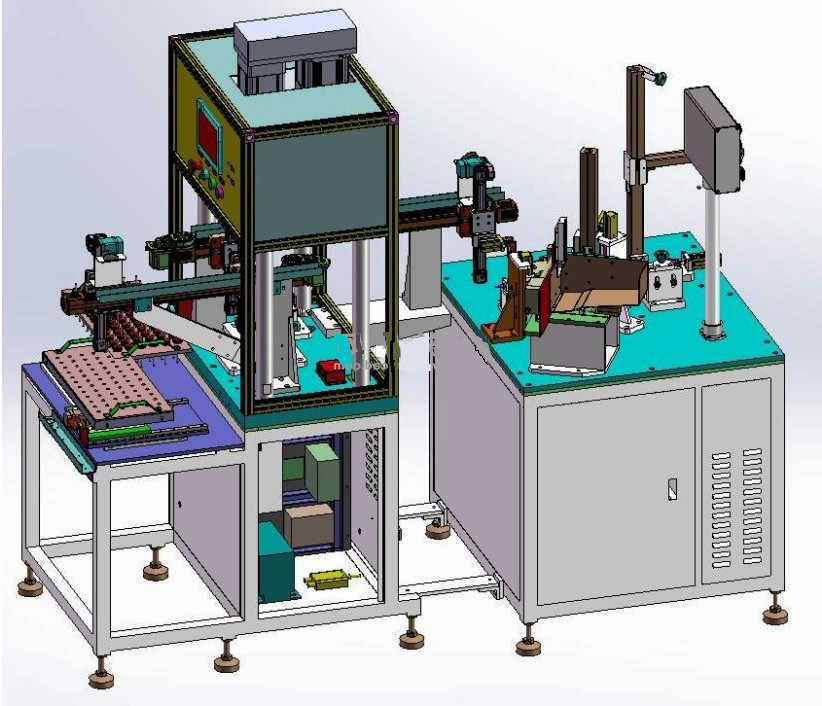

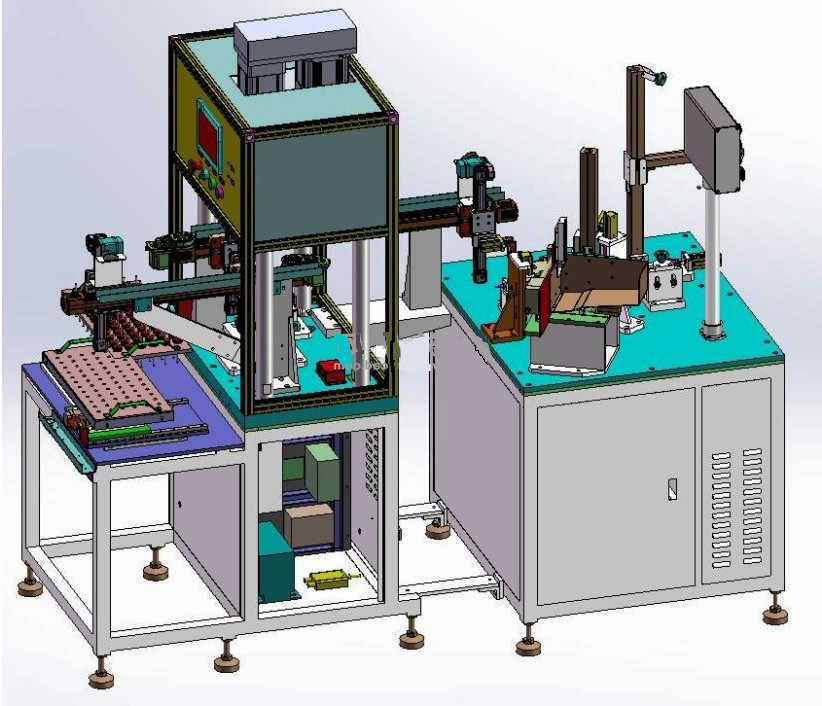

Precision Non-Standard Automation Equipment

Qingdao Chuancheng Precision Electromechanical Co., Ltd – Your trusted partner in industrial automation, fixture design, mold processing, and high-precision mechanical components.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Qingdao Chuancheng Precision Electromechanical Co., Ltd – Your trusted partner in industrial automation, fixture design, mold processing, and high-precision mechanical components.

Founded in 2016 with a registered capital of 5 million yuan, Qingdao Chuancheng Precision Electromechanical Co., Ltd is a professional enterprise dedicated to the R&D and production of non-standard industrial automation equipment.

We specialize in supporting automatic chemical plants and industrial manufacturing lines with customized automation solutions. Our expertise spans mechanical equipment processing, mold development, and precision machining of accessories.

With an annual production and design capacity to support over 1,000 automation systems, we deliver high-quality, high-precision equipment tailored to client specifications.

High-precision non-standard automation equipment, fixtures, molds, and machined parts for diverse industrial applications.

Fully automated assembly systems for electronic switches, ensuring high efficiency and precision in production.

Integrated production line for coil winding, insulation, and testing, designed for high-volume output.

Specialized automation system for assembling clutch springs with consistent torque and durability.

Precision machinery for rotor core stacking, shaft insertion, and balancing in motor manufacturing.

Complete solutions for motor assembly including bearing press-fit, stator insertion, and final testing.

Automated systems for precise wiring and connection of touch screen panels in consumer electronics.

CNC-based drilling and chamfering system with robotic loading/unloading for high throughput.

Industrial-grade electrical cabinets for control systems integration in automation lines.

Custom-designed tooling and jigs for unique manufacturing processes and component handling.

Precision mold design and manufacturing for plastic injection, stamping, and die-casting applications.

High-tolerance machined parts and components for integration into larger automation systems.

Turnkey solutions for assembling consumer electronics, including testing and packaging modules.

Every piece of equipment is tailored to your specific production needs and technical requirements.

Utilizing advanced CNC and metrology tools to ensure micron-level accuracy in every component.

From concept and design to manufacturing, installation, and after-sales support.

Over 1,000 automation systems designed and delivered annually to global clients.

Non-standard automation equipment refers to custom-designed machinery built for specific manufacturing processes that cannot be fulfilled by standard off-the-shelf machines. These systems are tailored to unique production requirements.

Yes, we specialize in custom design and engineering. Provide your technical requirements, production goals, and space constraints, and our team will develop a solution tailored to your needs.

We serve automotive, electronics, consumer goods, industrial machinery, and chemical processing industries with automation, fixtures, and precision components.

Yes, we provide on-site installation, commissioning, and operator training to ensure smooth integration into your production line.

Lead times vary based on complexity, but typically range from 60 to 120 days. We provide detailed project timelines during the quotation phase.

For inquiries, quotes, or technical consultations, visit our official website to contact the team directly.

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info