About XINKE HEAVY MACHINERY

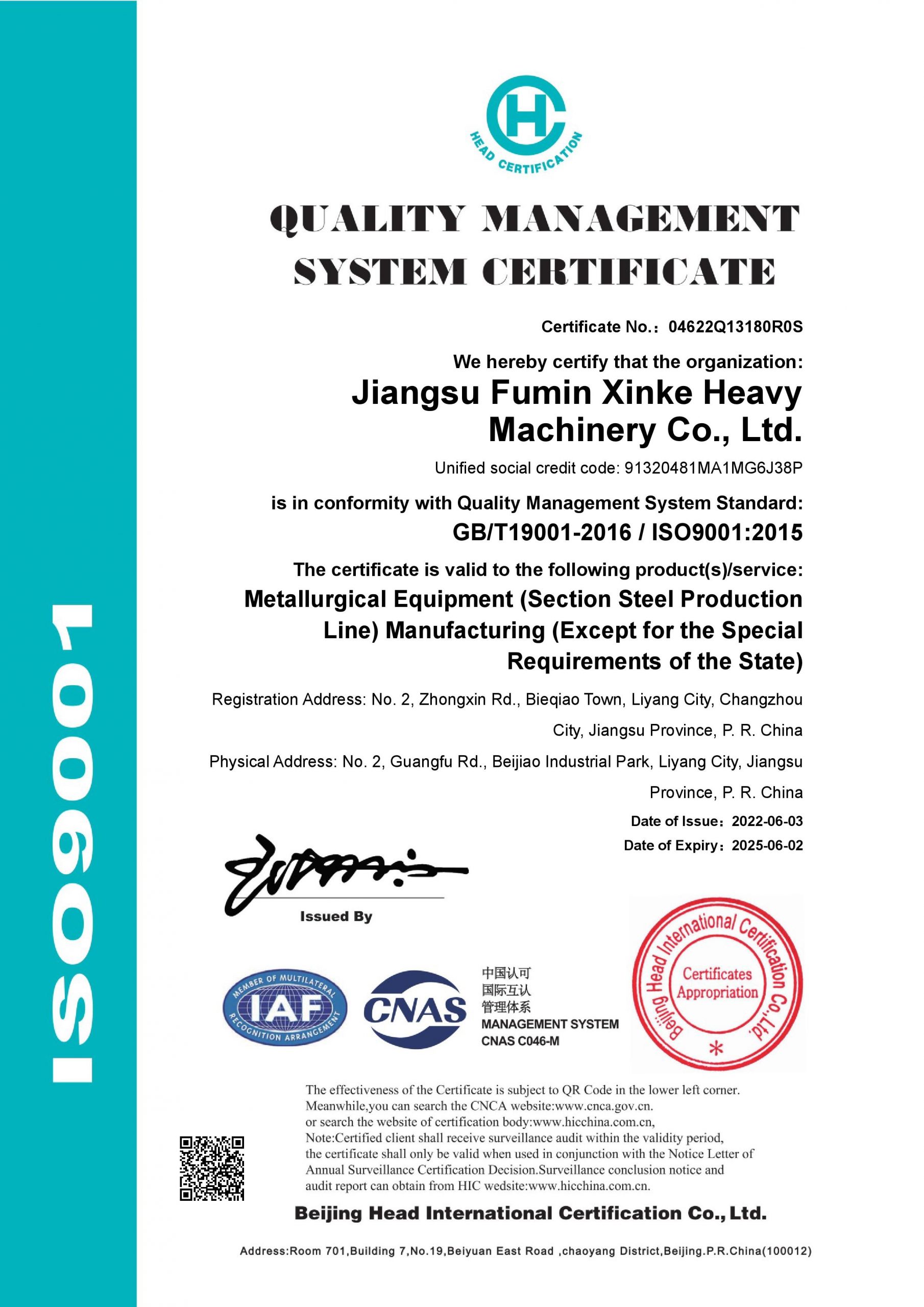

Jiangsu Fumin Xinke Heavy Machinery Co., Ltd (XINKE HEAVY MACHINERY) is a leading professional supplier and manufacturer of metallurgical equipment located in Liyang City, Jiangsu Province, in the heart of the Yangtze River Delta. With over 20 years of experience, we specialize in the R&D, design, manufacturing, installation, and commissioning of complete steel rolling production lines.

We have successfully built more than 300 steel rolling production lines for clients across the globe. Our self-invested 1,000,000 TPA hot rolling mill lines demonstrate our commitment to innovation and quality. We offer advanced equipment, superior pass design, energy efficiency, long service life, and low spare parts consumption—delivering exceptional economic value to our customers.