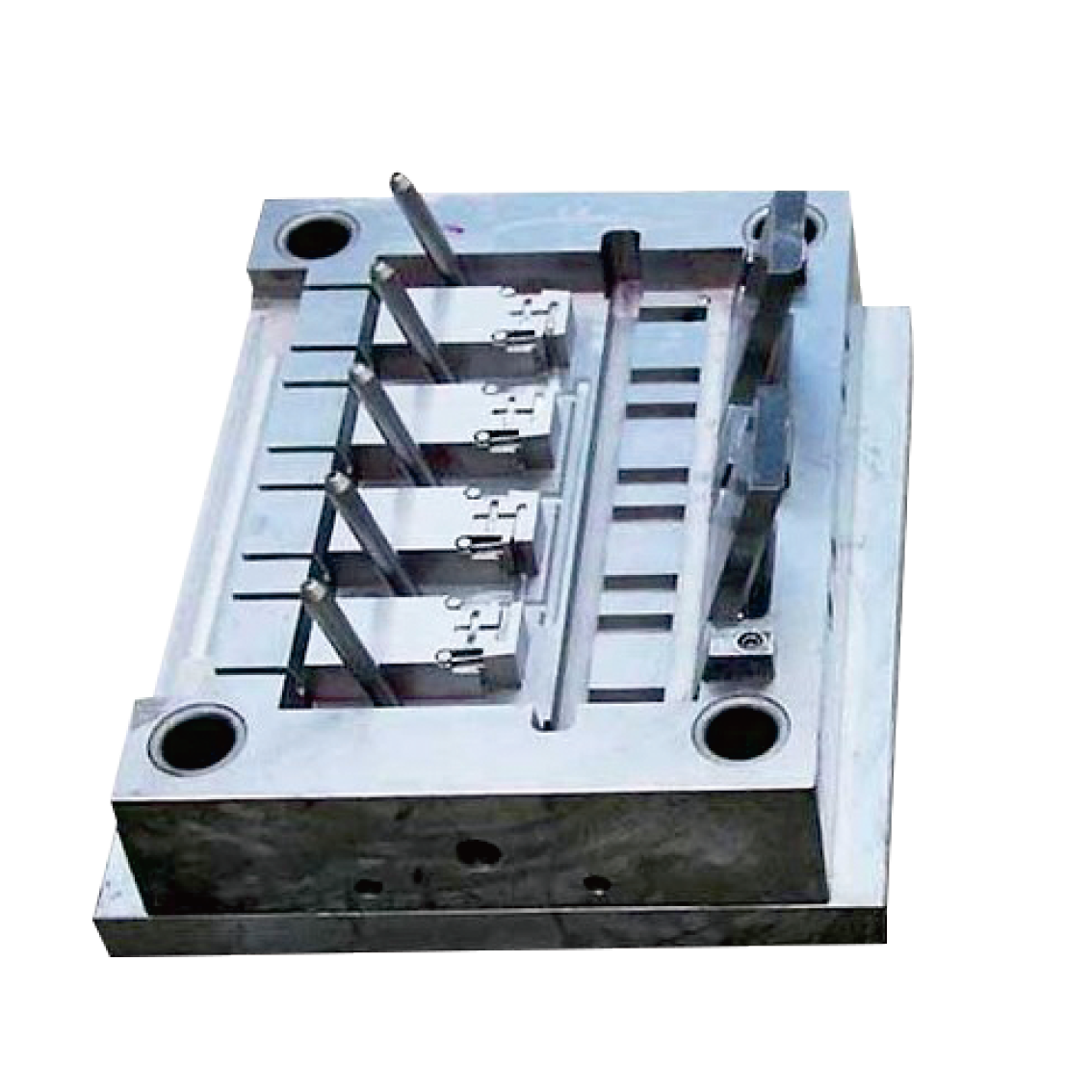

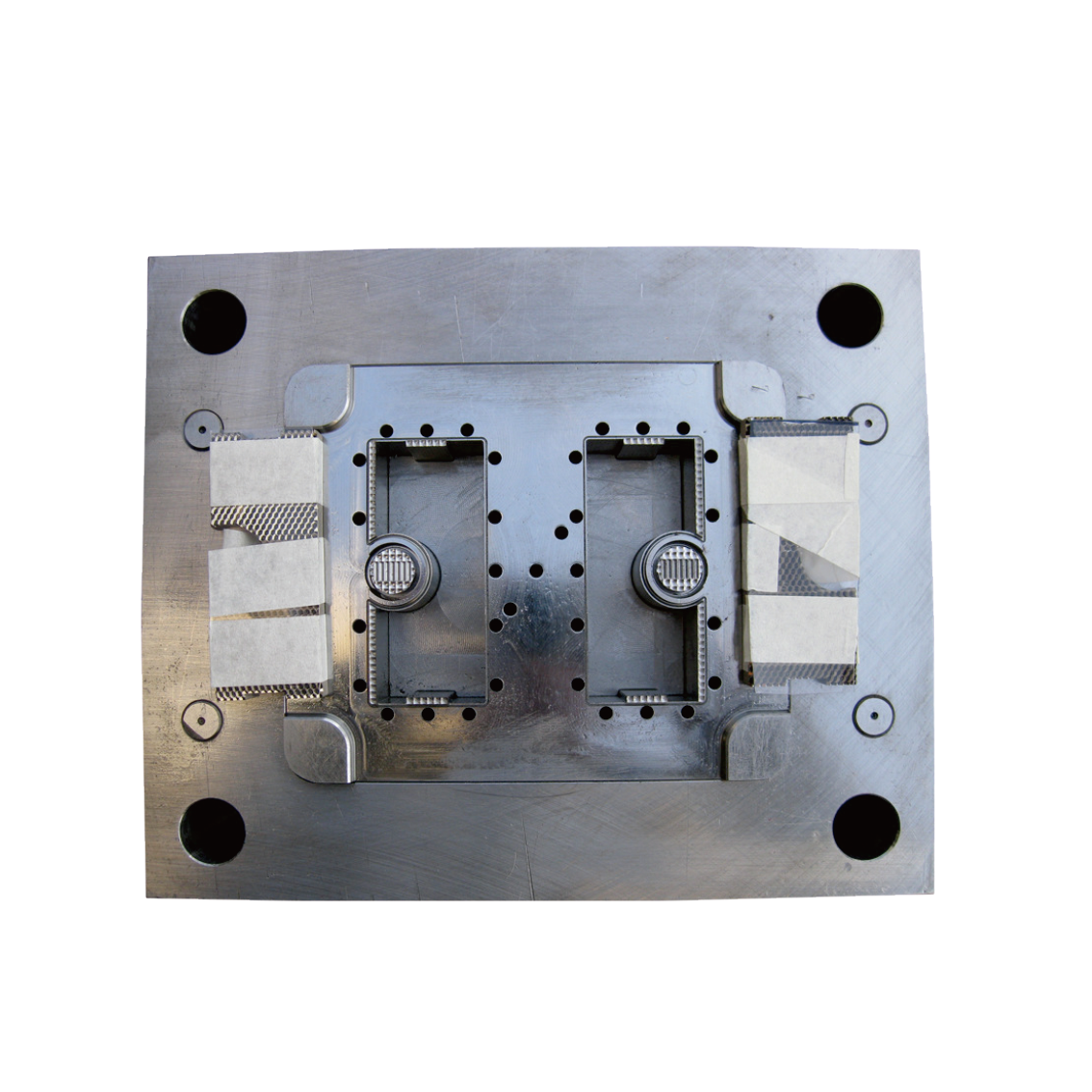

About R&S Tool Manufacturing

R&S Tool Manufacturing Limited specializes in custom plastic tooling and molding. Our company was founded in 2011 and is located in Dongguan, Guangdong, China — the hub of mold-making in Asia.

We provide comprehensive design, build, manufacture, repair, and maintenance solutions for clients around the world. For over 10 years, we have been known for our capability in manufacturing a wide range of components used in the automotive, industrial, and household sectors.