About RuiShi Group

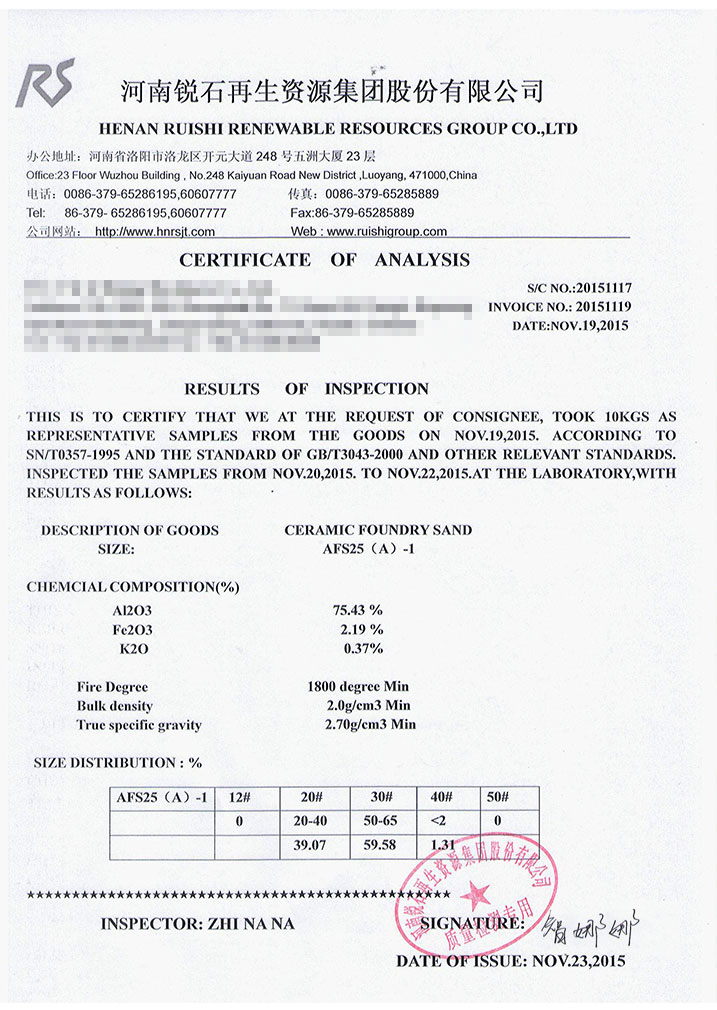

RuiShi Group is a trusted manufacturer specializing in high-quality fused and sintered alumina products, calcium aluminates, and advanced refractory materials. With years of expertise in industrial smelting and material science, we deliver reliable, high-performance solutions for abrasive, metallurgical, and construction industries.

Our commitment to quality, innovation, and customer satisfaction has positioned us as a preferred supplier across global markets. From raw material selection to final packaging, every step is monitored for consistency and excellence.