About SG Mould

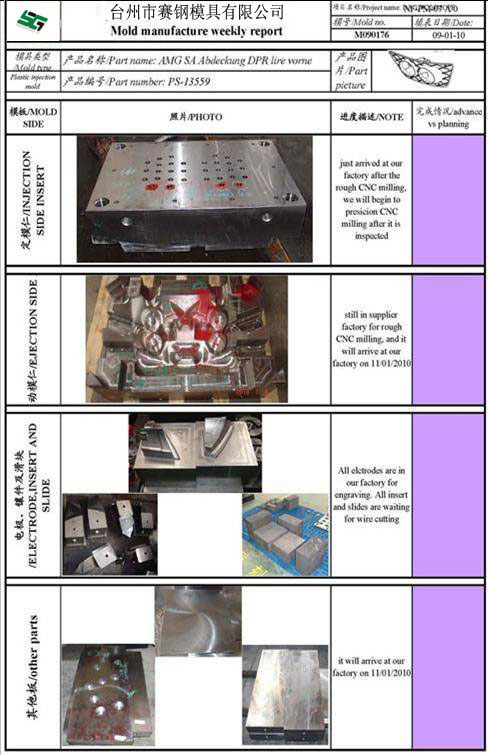

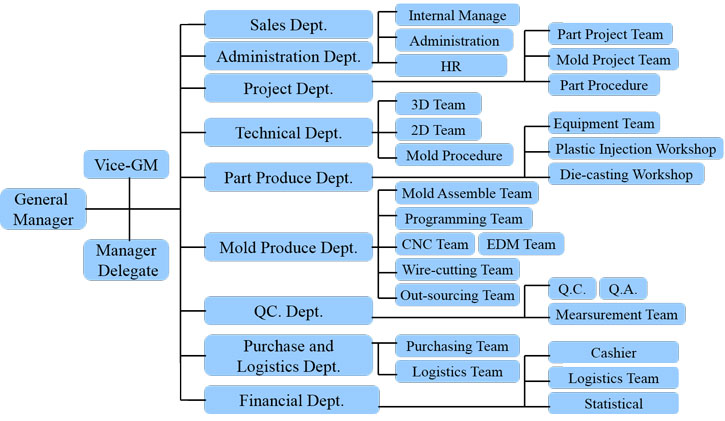

Taizhou Saigang Mould Co., Ltd. is a professional plastic mold manufacturer based in Taizhou, Zhejiang, China. With years of expertise in complex injection molding, we deliver precision-engineered solutions for the automotive, appliance, and industrial sectors.

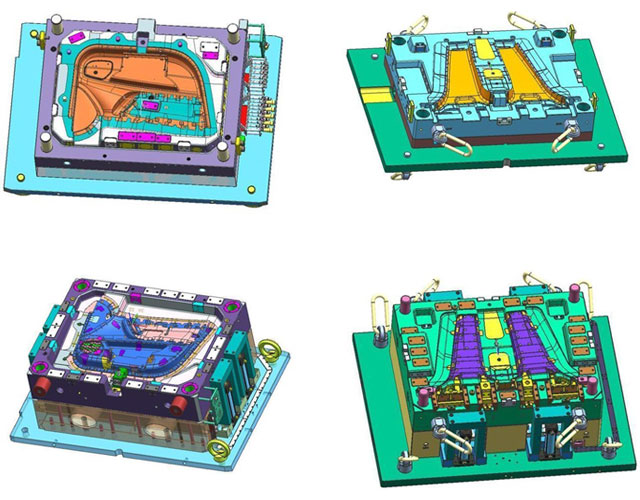

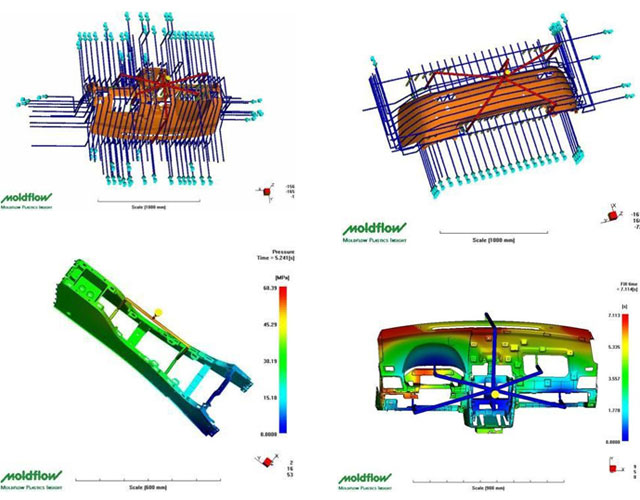

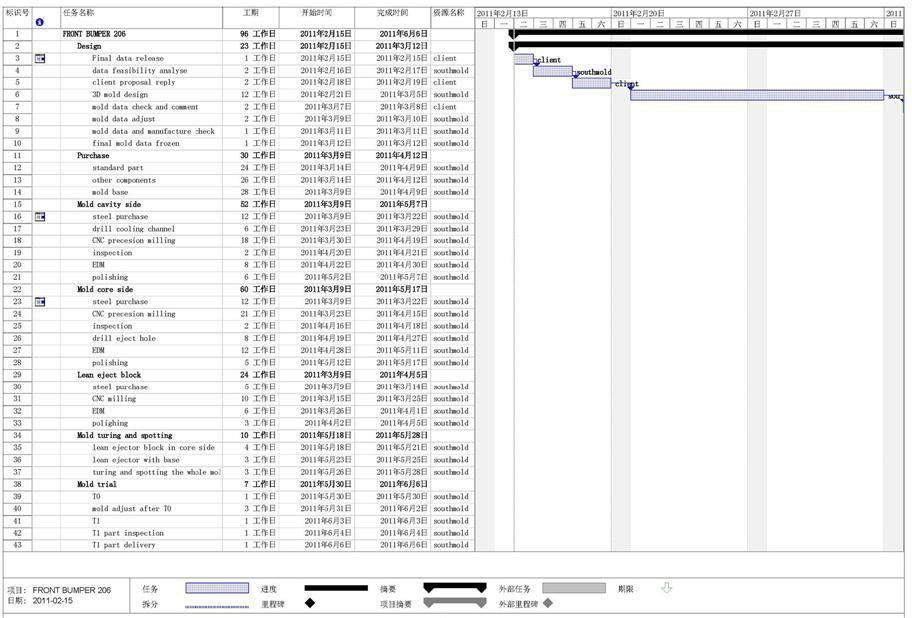

Our core focus lies in automotive molds — including bumpers, lamps, control panels, door trims, and interior decoration components. We also produce molds for home appliances, commodity goods, pipe fittings, and offer capabilities in die-casting and blow molding.

Automotive Expertise

Specialized in high-tolerance molds for global OEMs

Global Export

Direct export to Indonesia, Malaysia, Europe, and beyond