About Sino Techfull

Your trusted partner in textile manufacturing innovation with decades of engineering excellence.

Customer-Centric Innovation Since 2010

SINO TECHFULL is a reliable partner in the narrow fabric manufacturing industry, offering complete technical solutions from warping and thread covering to weaving and finishing. With deep-rooted expertise, we design and supply advanced machinery that meets the evolving demands of industrial webbings, functional tapes, fashion ribbons, and specialty textiles.

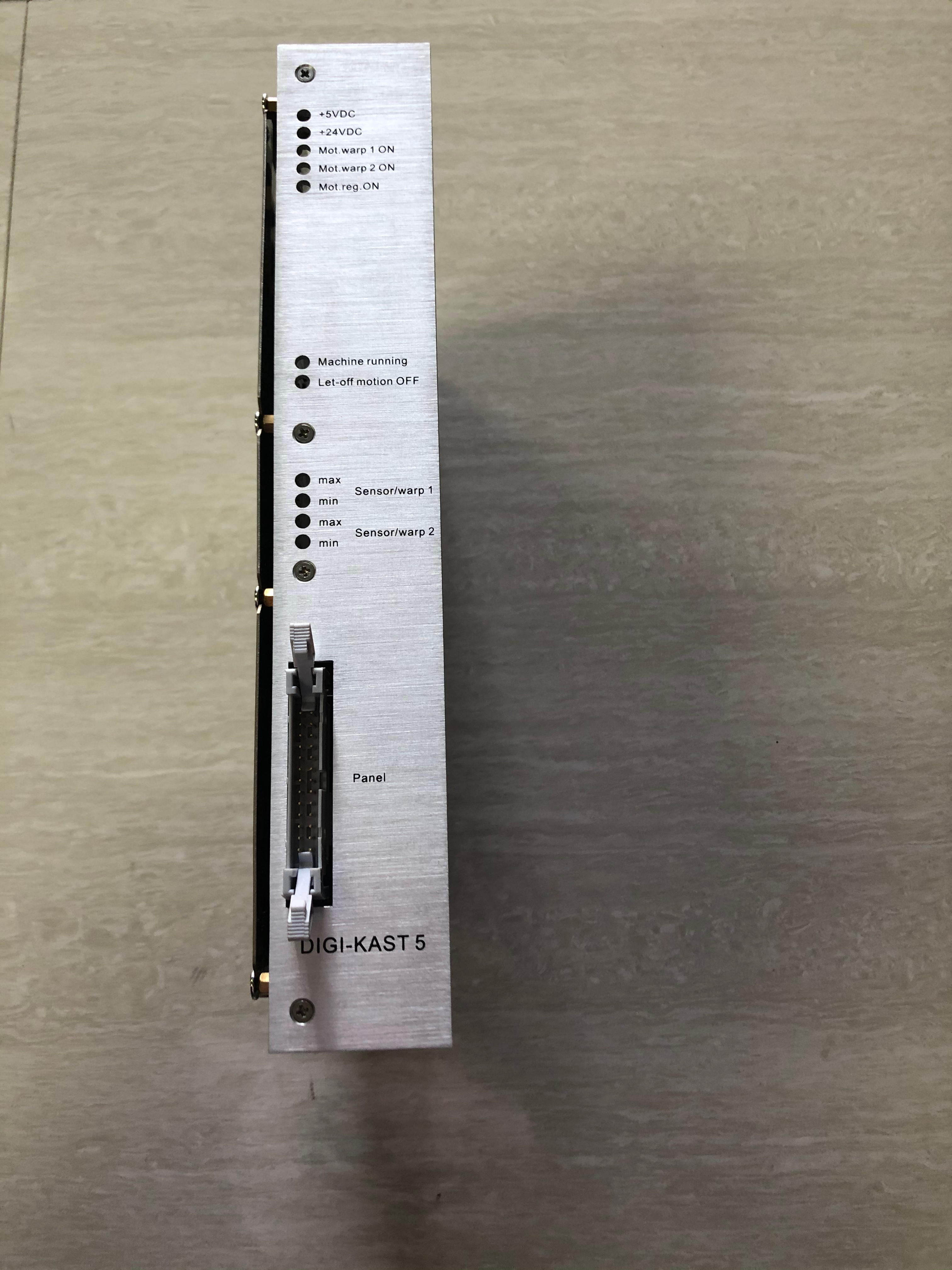

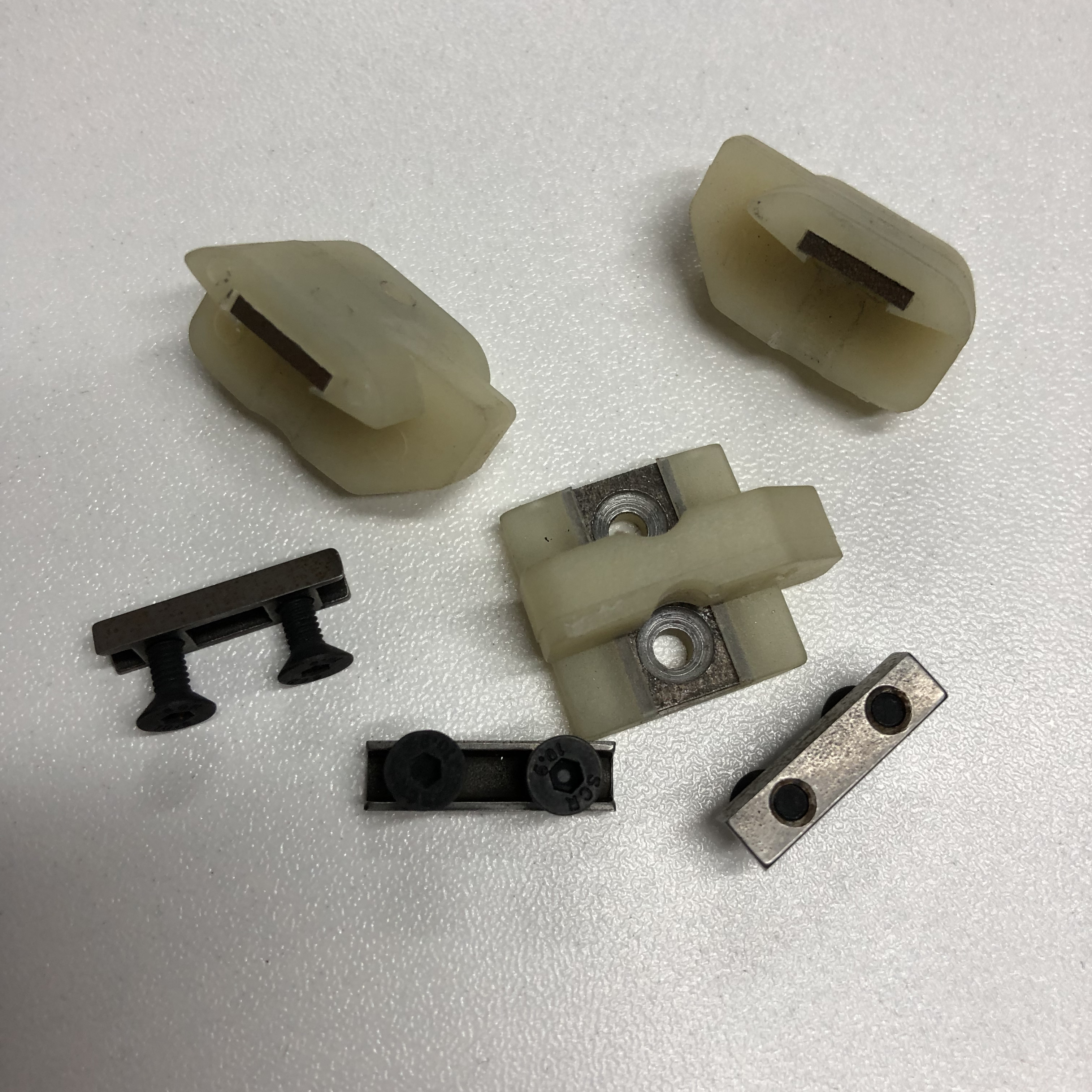

Backed by first-class manufacturing facilities and a dedicated team of engineers and technicians, we provide premium-quality spare parts for both narrow and broad fabric looms. Our one-stop service model simplifies procurement, ensures consistent quality, and helps customers maintain optimal production uptime.