Robots Take the Work Out of Work

Enjoy the luxury of autonomous welding services with our trackless, unguided, all-position crawling robots — redefining precision, efficiency, and safety in industrial welding.

Explore Our RobotsThis page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Enjoy the luxury of autonomous welding services with our trackless, unguided, all-position crawling robots — redefining precision, efficiency, and safety in industrial welding.

Explore Our RobotsBeijing Bo Tsing Tech Co., Ltd. is a national-level high-tech enterprise established in January 2017, specializing in the research, development, production, and sales of advanced intelligent welding robots.

With headquarters in Beijing and subsidiaries in Anhui (R&D) and Jiangsu (manufacturing), we operate a 3,000 sqm production base equipped with two automated lines, enabling an annual output of over 500 welding robots.

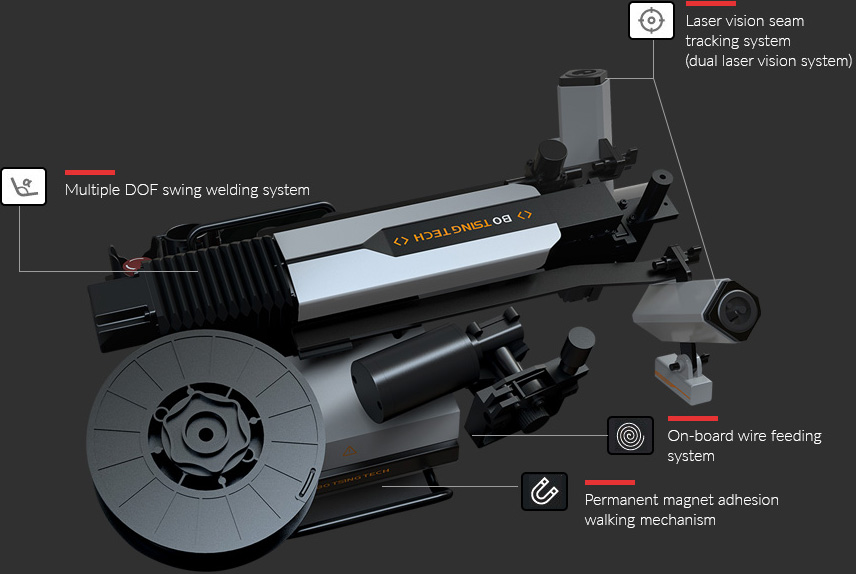

Engineered for precision, durability, and full autonomy — our trackless, unguided robots deliver ±0.2mm weld tracking accuracy across all positions and pipe diameters.

No programming or guiding tracks needed — robots navigate and weld independently using AI and vision systems.

Laser vision and multi-sensor fusion ensure unmatched weld seam tracking accuracy in all conditions.

Our robots meet and exceed national and EU safety and quality standards.

We manufacture our own welding consumables to ensure quality and supply chain reliability.

Fully automated circumferential and longitudinal seam welding with zero human entry into hazardous zones.

Precision orbital welding on curved surfaces using adaptive path planning and real-time monitoring.

Robots deployed in confined underground spaces for structural reinforcement with remote supervision.

Corrosion-resistant robot completed internal welds in buried tanks with full traceability and QA logs.

For inquiries, support, or custom solutions, visit our official website to connect with our team.

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info