Spun-Castings

Spun-Castings

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Spun-Castings

Spun-Castings

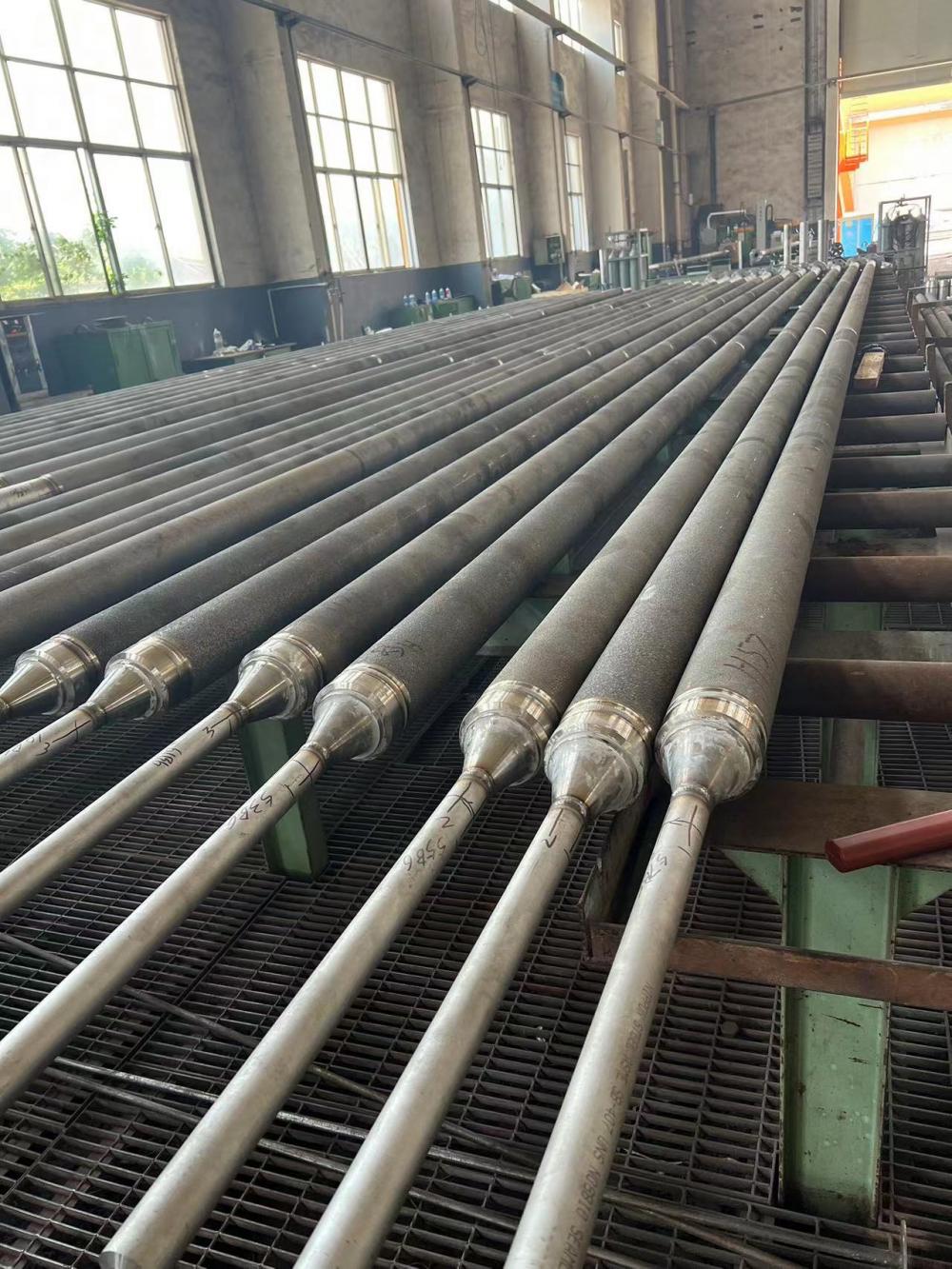

Manufacturer of high-performance radiant tubes, reformer tubes, cracking tubes, furnace rollers, cast base trays, and wear-resistant components for metallurgical, petrochemical, and power industries.

Jiangsu Taigoo New Material Co., Ltd. is a leading manufacturer specializing in centrifugal casting tubes and static castings in heat-resistant alloys. With over two decades of experience, we have developed proprietary technologies and deep expertise in high-temperature alloy manufacturing.

Our products serve critical roles in metallurgical, petrochemical, and engineering industries — including Steam Reformer Tubes, Ethylene Cracking Tubes, Furnace Rolls, Radiant Tubes, DRI Reformer Tubes, Cast Base Trays, Cast Baskets, and Wear-Resistant Castings.

High-performance centrifugal castings and static cast components engineered for extreme heat, pressure, and wear conditions across industrial sectors.

High alloy centrifugal cast radiant tubes for continuous annealing and galvanizing lines. Resistant to thermal cycling and oxidation at high temperatures.

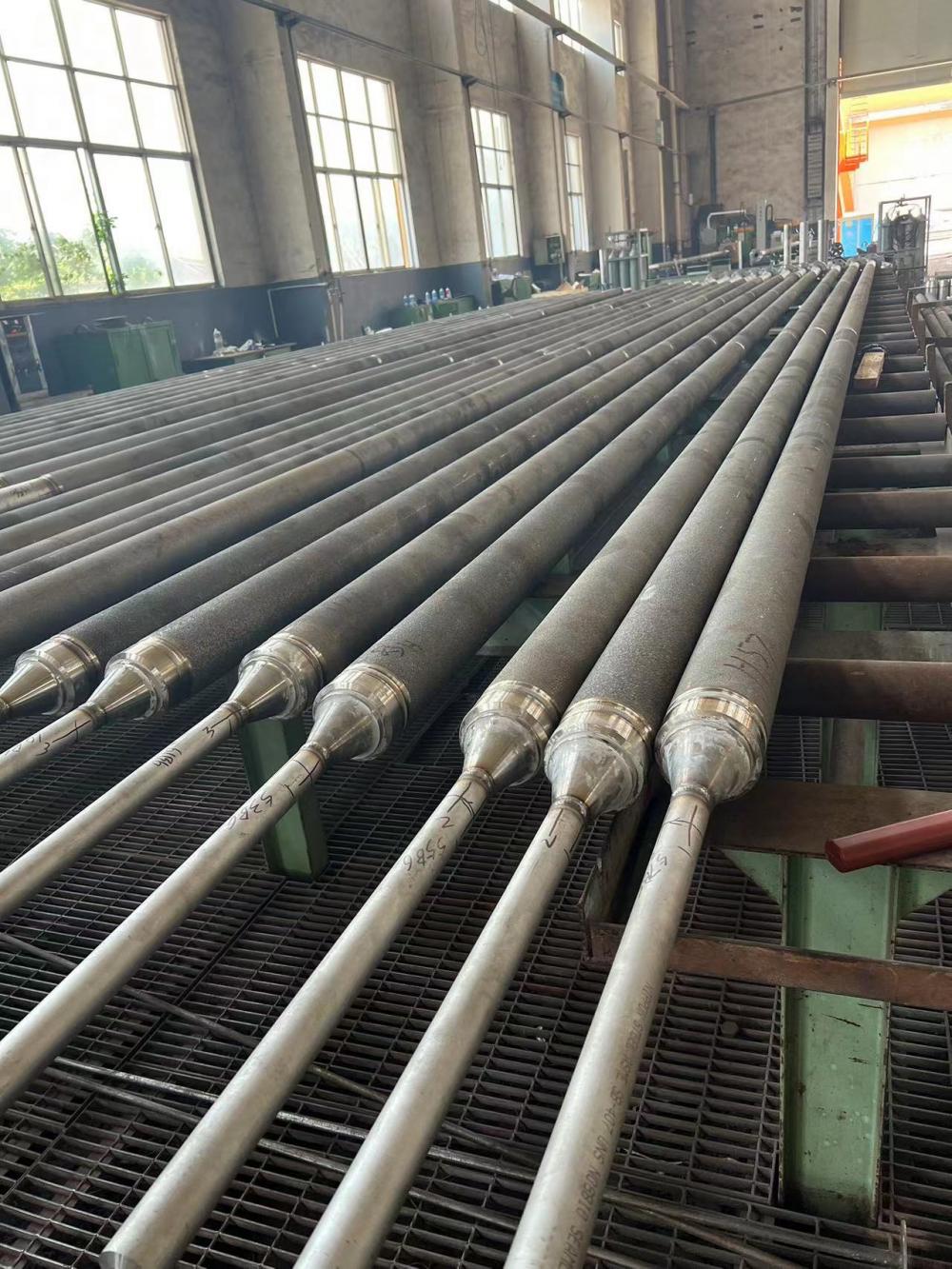

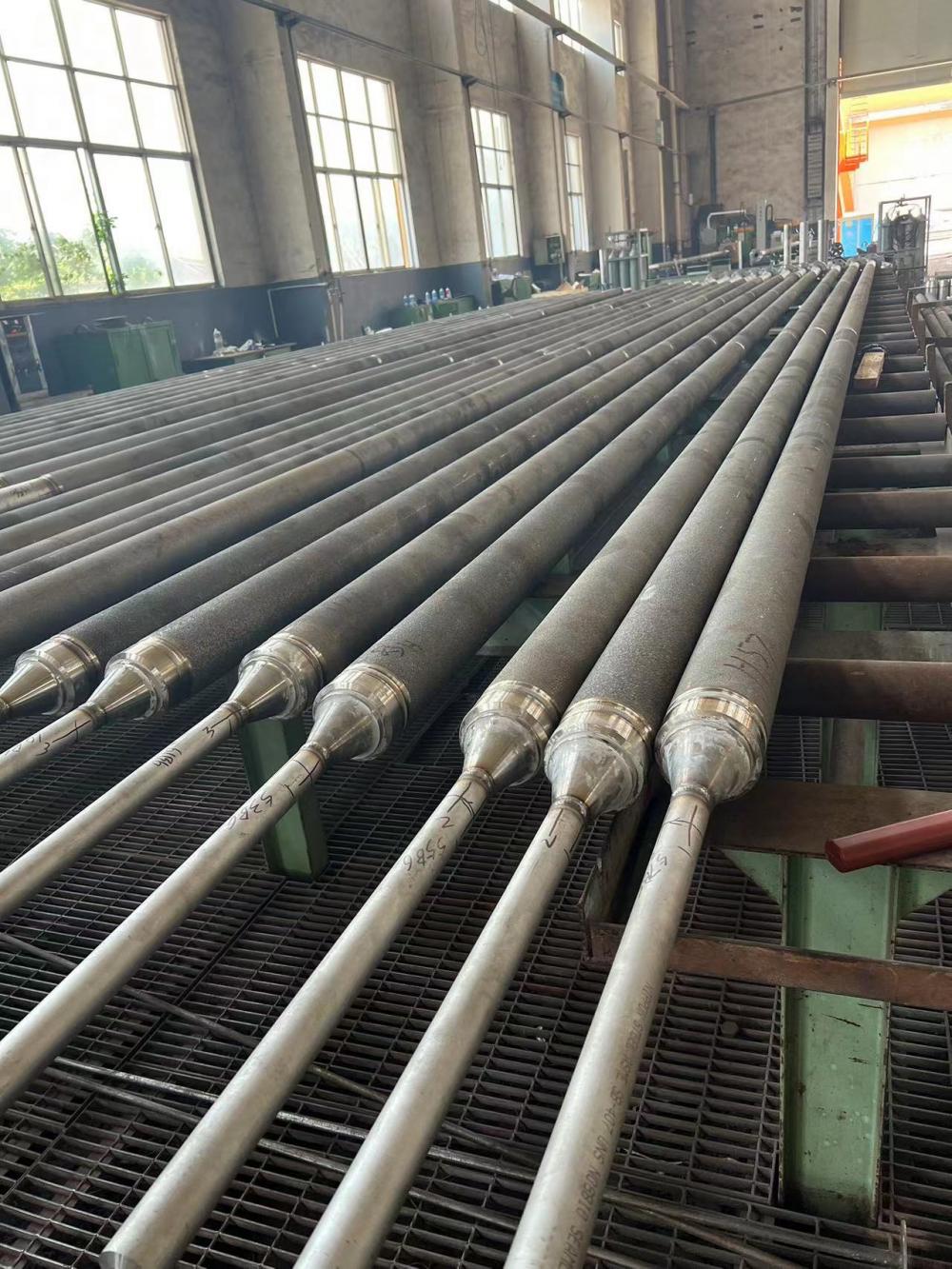

Centrifugal cast reformer tubes for hydrogen generation and ethane dehydrogenation plants. High creep resistance and long service life.

High-performance cracking tubes for petrochemical ethylene production units. Excellent thermal shock resistance and coking resistance.

Coating furnace rollers for continuous annealing lines (CAL) and galvanizing lines (CGL). Precision machined for uniform surface finish.

Heat-resistant cast base trays for heat treatment furnaces. Designed for durability under repeated thermal cycling and heavy loads.

Galvanizing line sink rolls with high corrosion resistance. Available in various alloys including Ni-resist and high-chrome iron.

Direct Reduced Iron reformer tubes for syngas production. High resistance to carburization and metal dusting.

Custom wear-resistant castings for steel mills and heavy industries. Made from high-chrome white iron and Ni-hard alloys.

Precision investment cast components for complex geometries. Ideal for turbine parts, valves, and pump housings.

Large-scale sand casting for heavy industrial components. Capable of producing parts up to several tons in weight.

Tubes, headers, and manifolds for high-temperature heat exchangers. Manufactured from heat-resistant alloys like HK40, HP40, and RA330.

High-strength piercing plugs for seamless tube manufacturing. Resistant to thermal fatigue and wear during hot rolling processes.

We combine advanced manufacturing, strict quality control, and deep industry knowledge to deliver reliable, long-lasting components.

Our centrifugal casting process ensures uniform wall thickness, fine grain structure, and superior mechanical properties under extreme conditions.

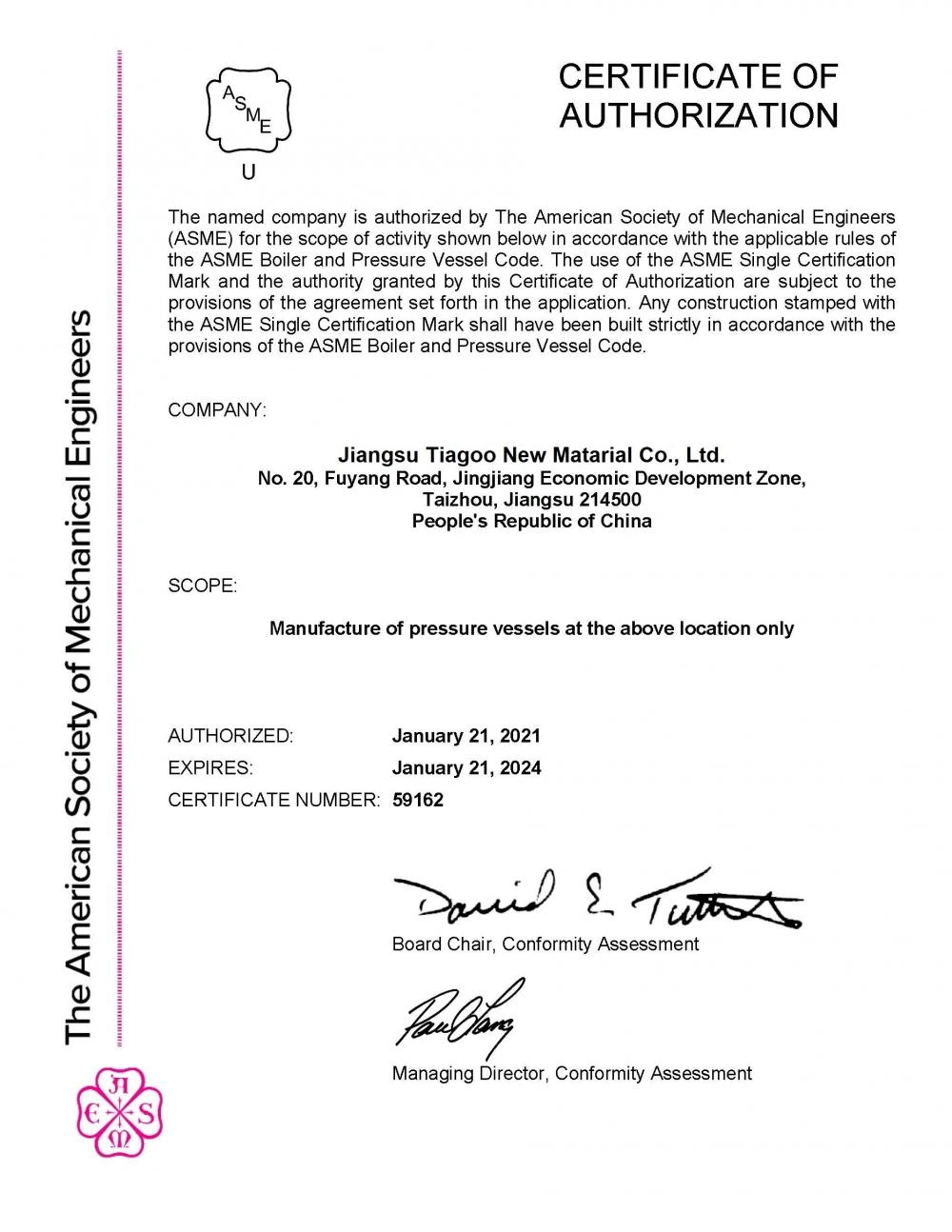

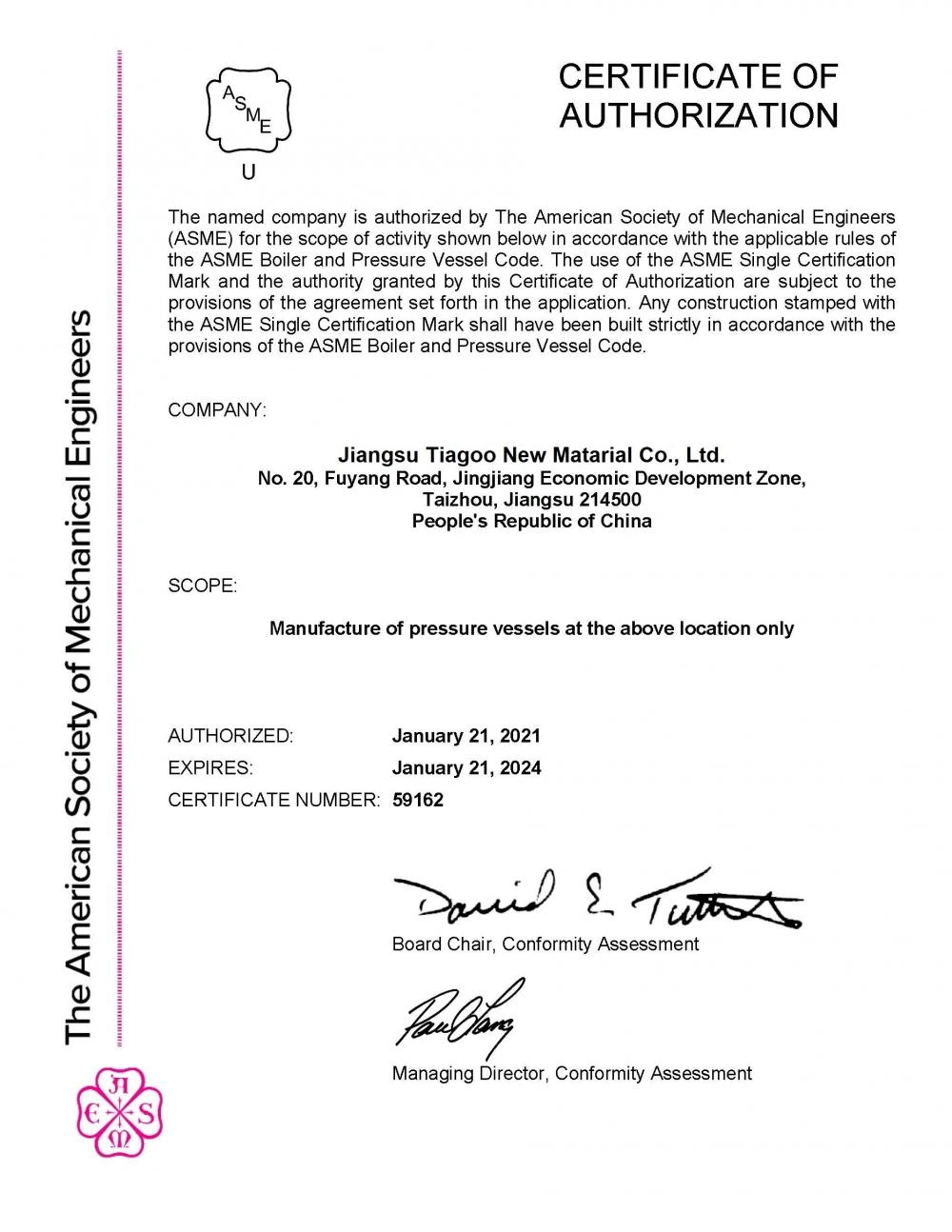

ISO 9001 certified with a complete quality system covering environment, occupational health, and safety. Every product undergoes rigorous testing.

Supplied to over 20 countries. Our components are used in hydrogen production, ethylene plants, steel mills, and power generation facilities worldwide.

From casting and heat treatment to precision machining and surface finishing — we handle every step in-house for consistent quality.

We design and manufacture custom castings based on your specifications, drawings, or samples — no project is too complex.

Our engineering team provides technical consultation, installation guidance, and after-sales service to ensure optimal performance.

Supply of high-temperature reformer tubes and radiant tubes for catalytic dehydrogenation process units.

Complete set of steam reformer tubes and convection section components for large-scale hydrogen generation.

Supply of pressure vessels and fired heater components for refinery desulfurization processes.

High-pressure, high-temperature resistant castings for refining applications.

Custom radiant tubes and heat exchanger components for styrene monomer production.

Furnace rollers and radiant tubes for steel strip heat treatment lines.

We use high-temperature alloys such as HK40, HP40, RA330, Inconel 601, and custom Ni-resist and high-chrome irons depending on application requirements.

Yes, we produce centrifugal cast tubes from 50mm to 1200mm in diameter and up to 12 meters in length based on customer drawings and specifications.

We serve metallurgical, petrochemical, oil & gas, power generation, and engineering industries globally.

Yes, we offer full in-house heat treatment, precision machining, and surface finishing to meet exact dimensional and performance requirements.

We are ISO 9001 certified with a comprehensive quality assurance system covering environmental and occupational health & safety standards.

Contact us for product inquiries, technical support, or custom manufacturing solutions.

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info