About SunCNC Precision Parts

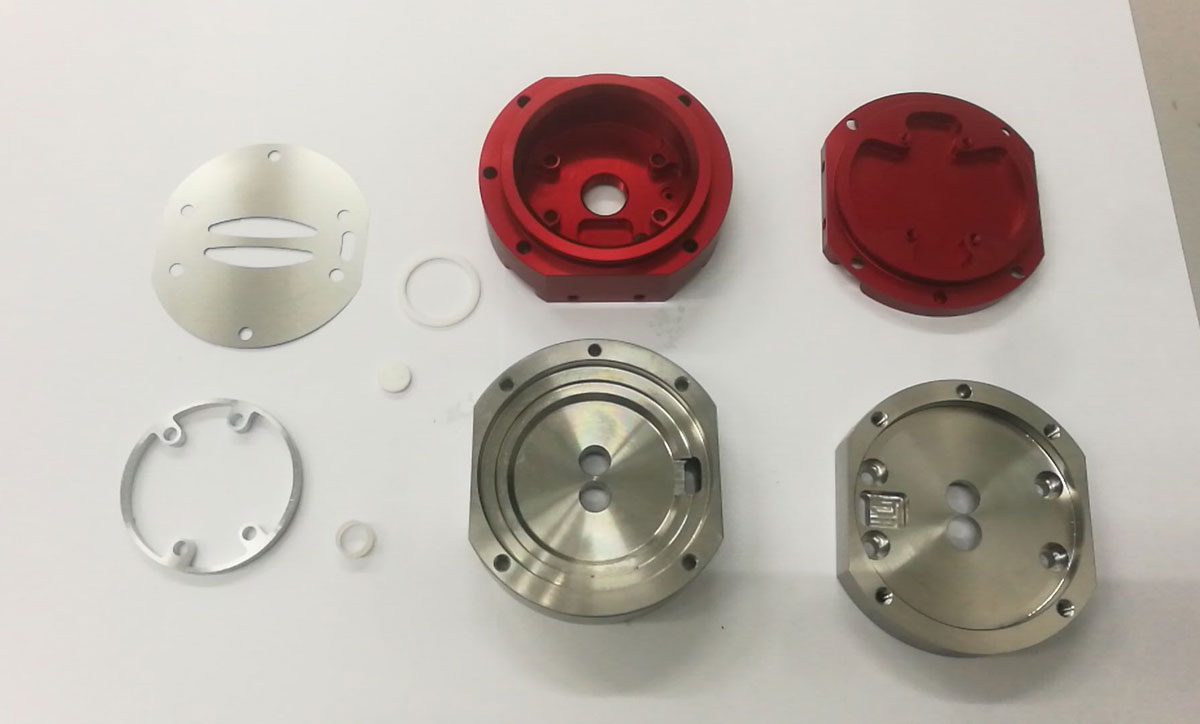

As a leading CNC machining service provider in China, Sun1 CNC Precision Parts Co., Ltd. has been delivering high-quality, precision-engineered components for over 20 years. Our expertise spans across industries including aerospace, medical, automotive, and industrial equipment.

We support 3-axis, 4-axis, and 5-axis CNC milling, CNC turning, lathe machining, right-angle milling, and sheet metal fabrication. Our capabilities allow us to rapidly create designs from simple geometries to complex, high-tolerance parts with consistent quality.

- 20+ Years of Industry Experience

- ISO-Certified Quality Standards

- Global Client Base in USA, Germany, Australia

- No Minimum Order Quantity