Premium Ceramic & Bimetallic Wear Parts

ISO9001:2015 certified foundry producing high-performance blow bars, hammers, liners, and custom wear solutions for mining, quarry, cement, and recycling industries.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

ISO9001:2015 certified foundry producing high-performance blow bars, hammers, liners, and custom wear solutions for mining, quarry, cement, and recycling industries.

SUNWILL is an ISO9001:2015 certified foundry specialized in manufacturing and innovation of wear parts for quarry, mining, cement, construction, aggregates, recycling, and other industries where longer service life wear parts are desperately needed to reduce downtime.

Annual Production Capacity

Casting Weight Range

Casting Lines

24/7 Customer Service

High-performance wear parts engineered for durability, efficiency, and extended service life in the most demanding industrial environments.

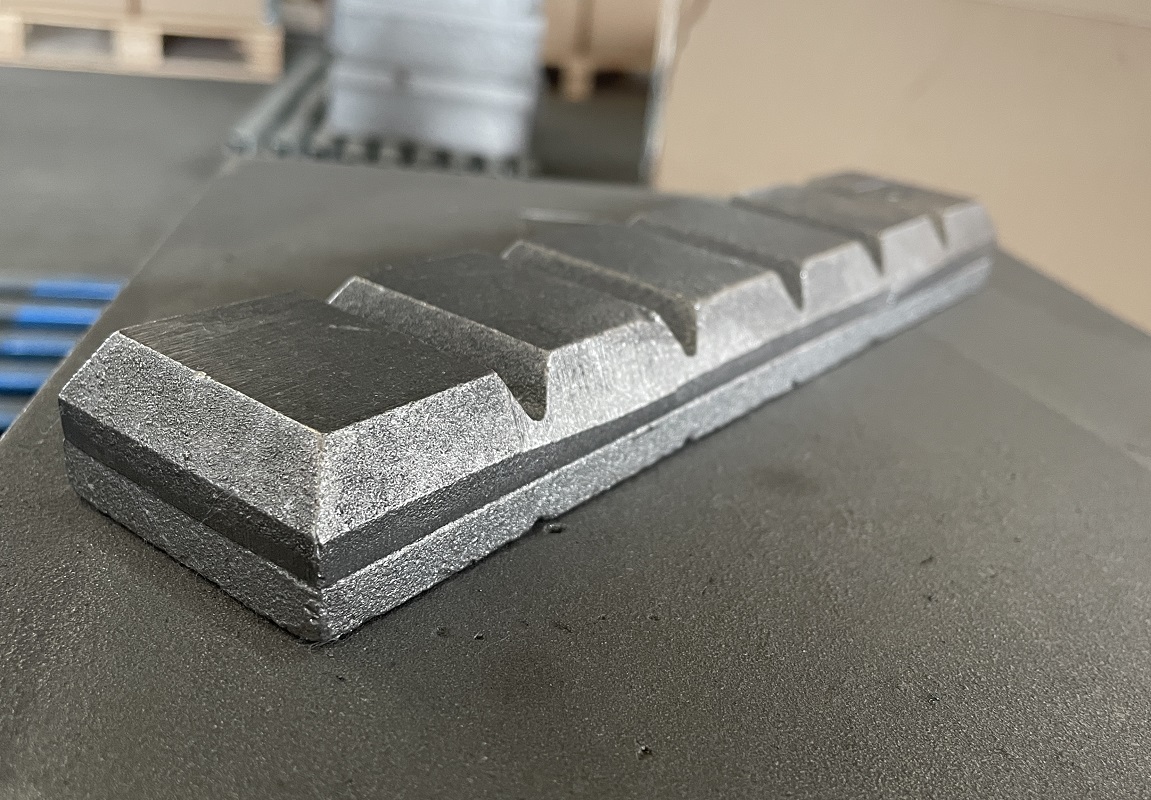

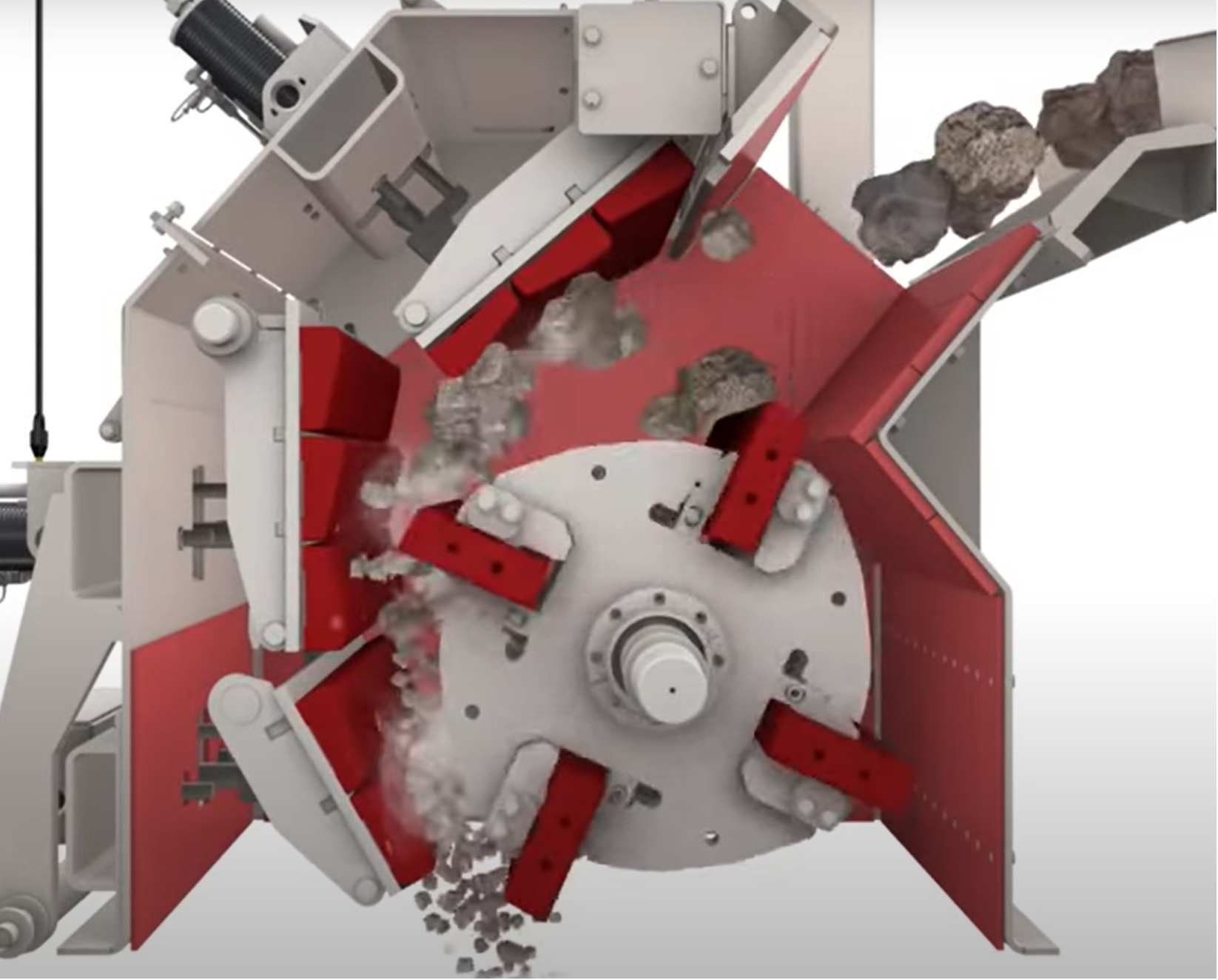

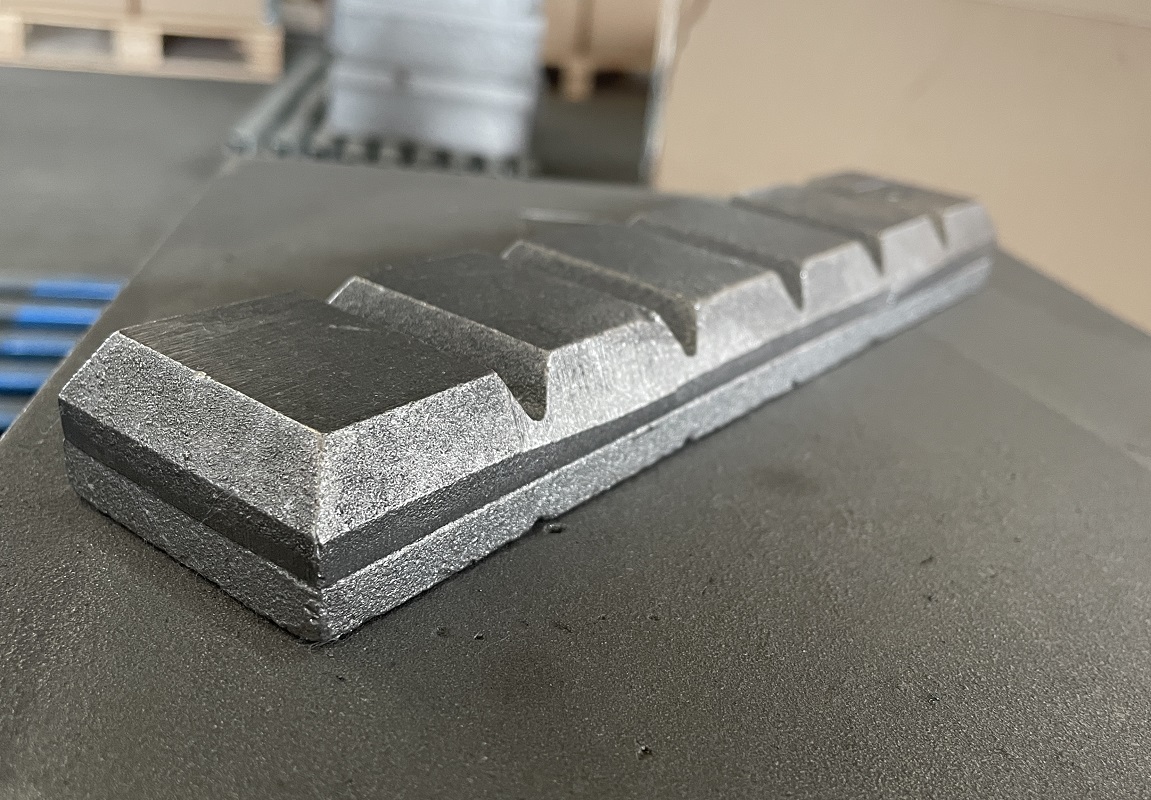

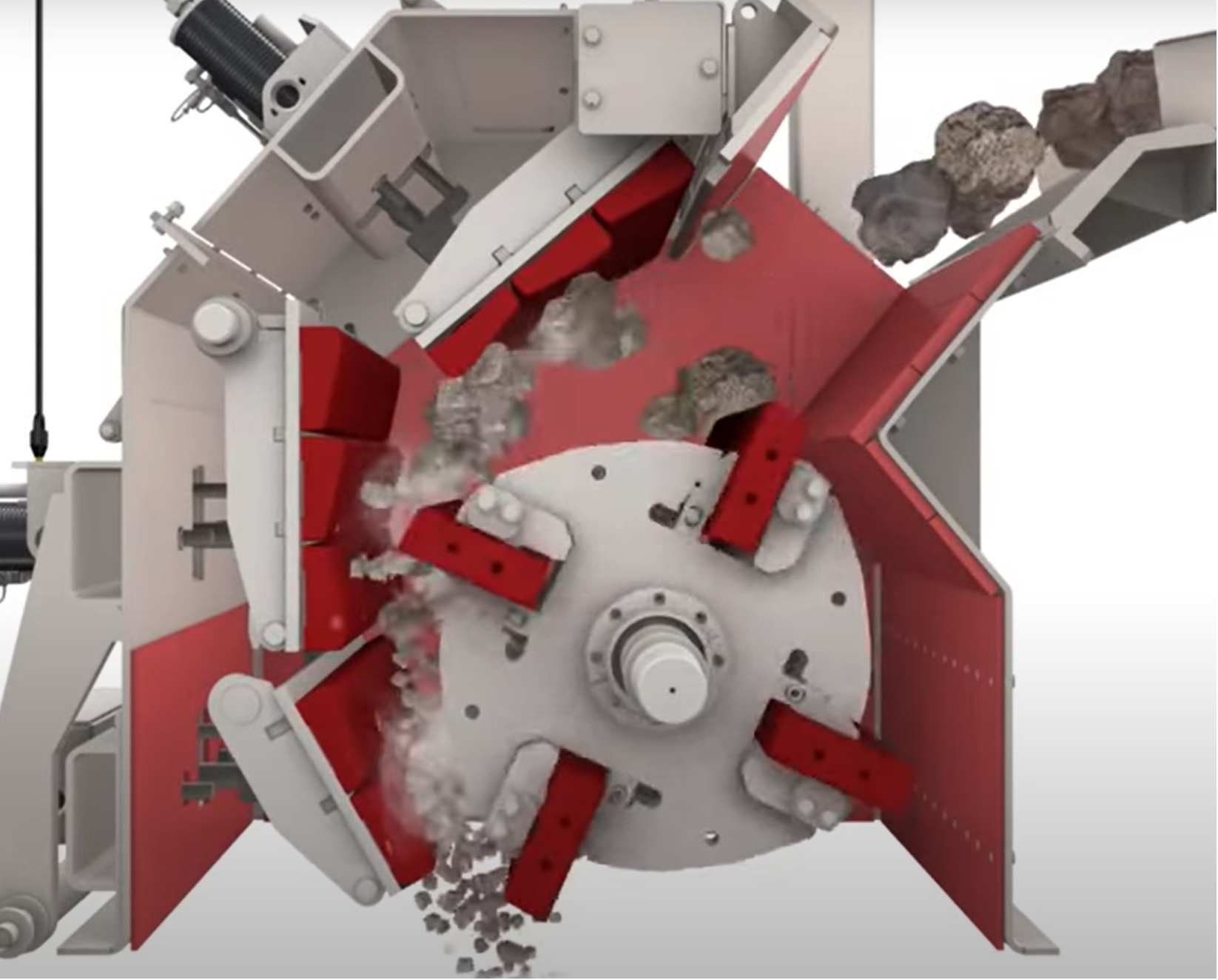

High-chrome ceramic composite blow bars with superior wear resistance for impact crushers.

Dual-layer construction with high-chrome surface and tough steel backing for maximum durability.

Forged and cast hammers for hammer crushers with optimized weight distribution.

Custom mill liners designed to optimize grinding efficiency and reduce maintenance.

High-strength concave segments for gyratory crushers with uniform wear characteristics.

Wear parts for vertical shaft impactors with high resistance to abrasion and impact.

Heavy-duty hammers for wood hogs, shredders, and recycling applications.

Tailored wear parts and engineering solutions for specific application challenges.

Leveraging cutting-edge casting techniques and composite materials to deliver superior wear performance.

Our proprietary MMC technology combines a tough steel matrix with embedded ceramic particles, creating a composite material that offers exceptional wear resistance while maintaining impact strength. This results in blow bars and wear plates that last significantly longer than conventional materials.

Bimetal wear parts feature a high-chrome, wear-resistant surface layer fused with a tough, impact-resistant steel backing. This combination delivers optimal performance—maximum wear life where it's needed most, with the structural integrity to withstand heavy impacts.

We utilize both sand casting and lost foam casting techniques, selecting the optimal method for each component to ensure dimensional accuracy, consistent quality, and superior mechanical properties.

Our wear parts are engineered for the most demanding applications across multiple sectors.

Crushers, screens, and conveyors requiring durable wear parts for rock processing.

Heavy-duty equipment for ore extraction and processing in challenging environments.

Raw mills, coal mills, and crushers requiring high-wear resistance components.

Shredders and size reduction equipment for metal, wood, and waste processing.

Heavy impact applications requiring maximum durability and safety.

Specialized shredder hammers and wear components for cane processing.

Annual Capacity

Casting Range

Customer Support

Global Clients

Ceramic blow bars utilize a metal matrix composite (MMC) structure where ceramic particles are embedded in a tough steel matrix. The ceramic provides extreme hardness and abrasion resistance, while the steel matrix absorbs impact energy. This combination can extend service life by 2-3 times compared to conventional high-chrome blow bars, especially in abrasive applications.

Bimetal wear parts consist of two distinct layers: a high-wear-resistant surface layer (typically high-chrome iron) metallurgically bonded to a tough, impact-resistant backing layer (usually low-alloy steel). This provides optimal performance—maximum wear life where the material contacts the product, with the structural integrity to withstand heavy impacts. Monolithic parts are made from a single material throughout, which may compromise either wear resistance or toughness.

Selection depends on several factors: feed material hardness and abrasiveness, feed size, desired product size, crusher rotor speed, and operating hours. For highly abrasive materials, ceramic or high-chrome blow bars are recommended. For high-impact applications with less abrasion, manganese steel may be more suitable. We offer application analysis to recommend the optimal solution for your specific conditions.

Yes, Sunwill specializes in custom wear solutions. We can manufacture wear parts to your exact specifications, including reverse engineering from samples. Our engineering team works with customers to analyze application requirements, select appropriate materials, and optimize design for maximum service life and performance.

Contact our team for product inquiries, technical support, or custom wear solutions.

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info