Engineered for Industrial Excellence

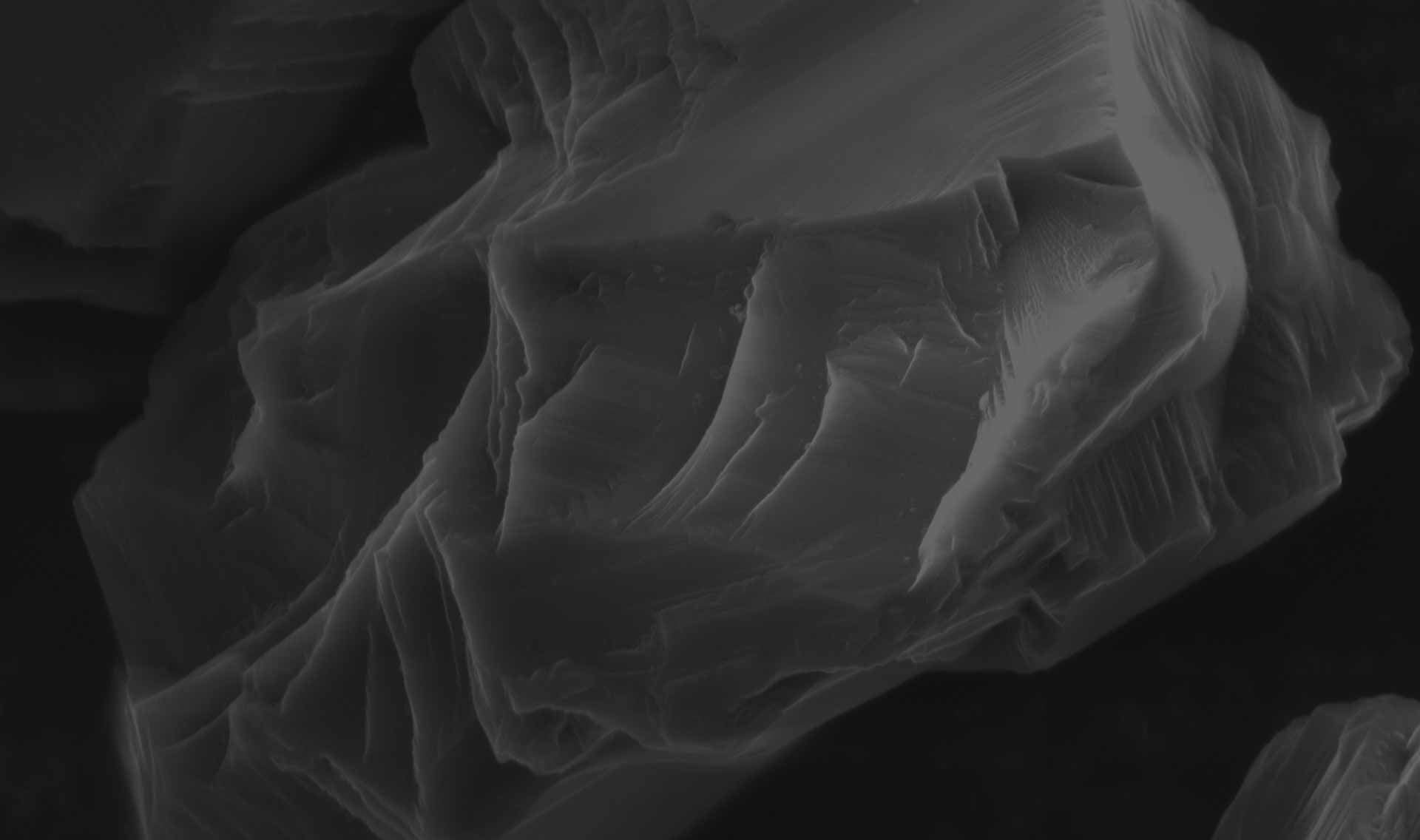

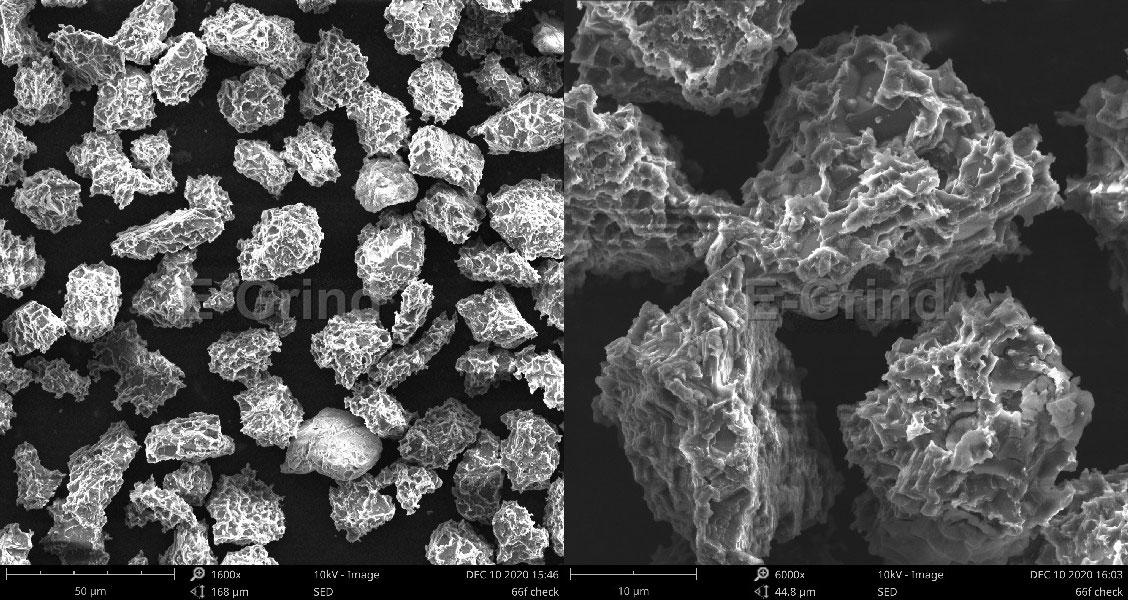

Henan E-Grind Abrasives Co., Ltd. is a leading manufacturer and supplier of superabrasive powders in China, specializing in synthetic diamond and cubic boron nitride (CBN) products. With years of expertise, we deliver high-performance abrasives trusted by industries worldwide.

Our advanced production techniques and strict quality control ensure consistent particle size, purity, and performance. Whether you're processing ferrous or non-ferrous materials, E-Grind provides the optimal abrasive solution.

- ISO-Certified Manufacturing

- Global Distribution Network

- Custom Particle Size & Coating