About Zhangjiagang Jiuqiang Machinery

Zhangjiagang Jiuqiang Machinery Manufacturing Co., Ltd. is a leading manufacturer of pipe processing and forming equipment located in Zhangjiagang, Jiangsu Province, China — a national civilized and sanitary city with a developed economy.

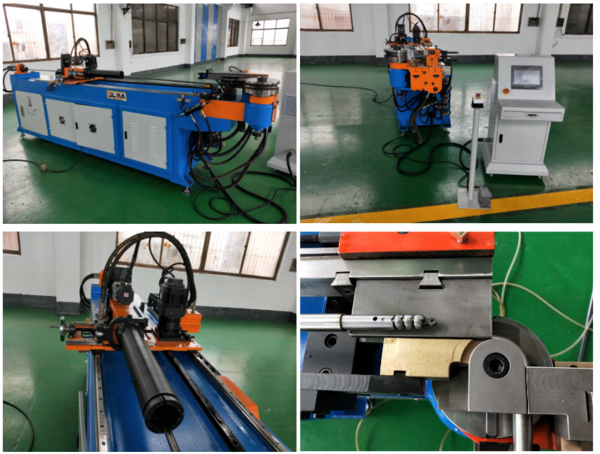

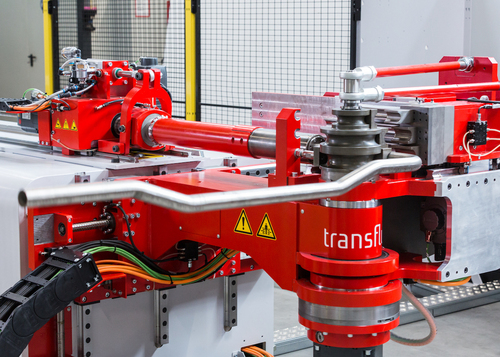

We specialize in the design and production of CNC pipe bending machines, pipe cutting machines, tube end forming machines, chamfering machines, metal circular saws, and complete pipe processing production lines.

Our products are widely used in industries such as boilers, aerospace, shipbuilding, new energy vehicles, air conditioning, furniture, and nuclear power.