Who We Are

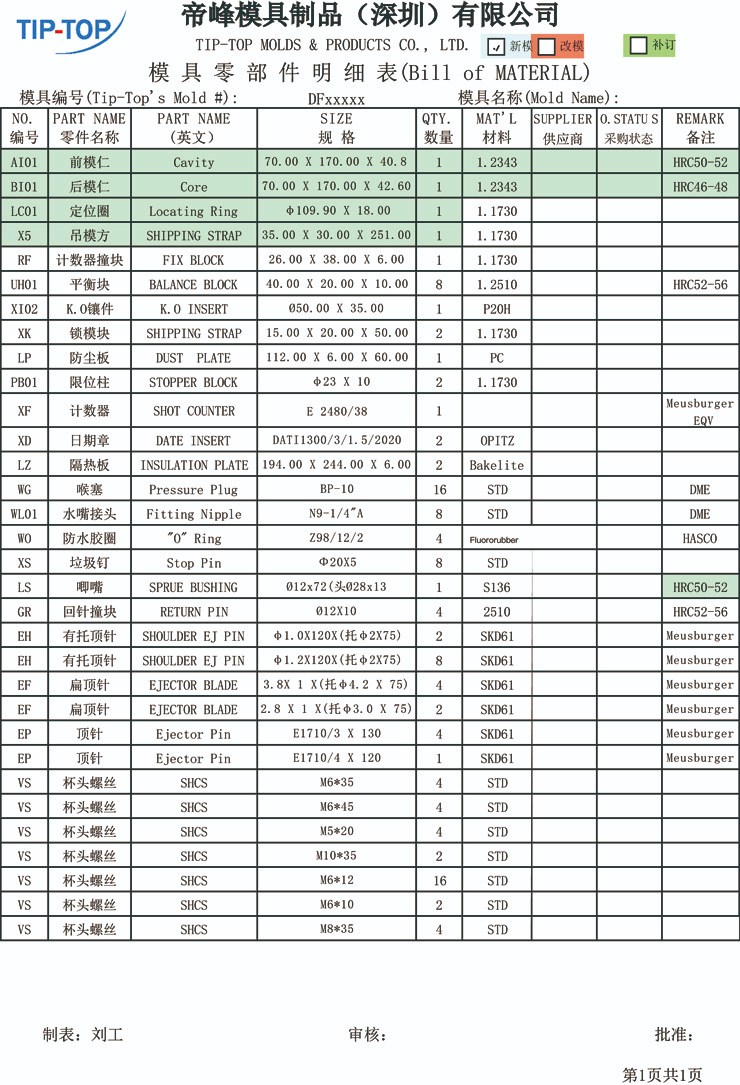

After more than 17 years of development, with rich experience, T2 Molds has the expertise to manufacture custom injection molds at a range of volumes and produce economical plastic molded parts for its customers.

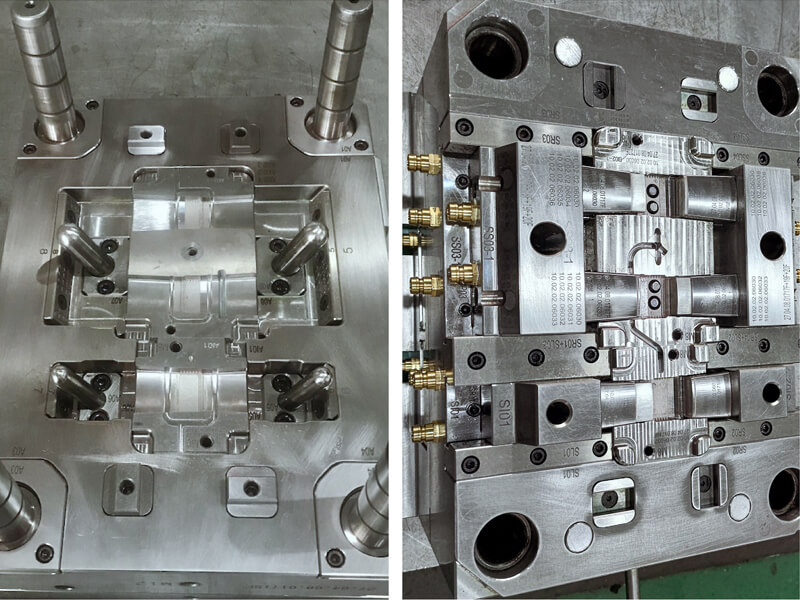

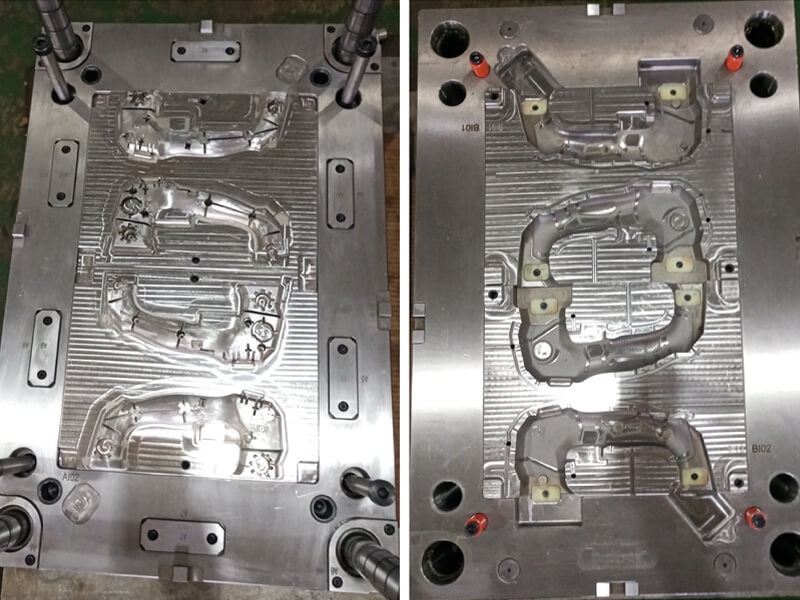

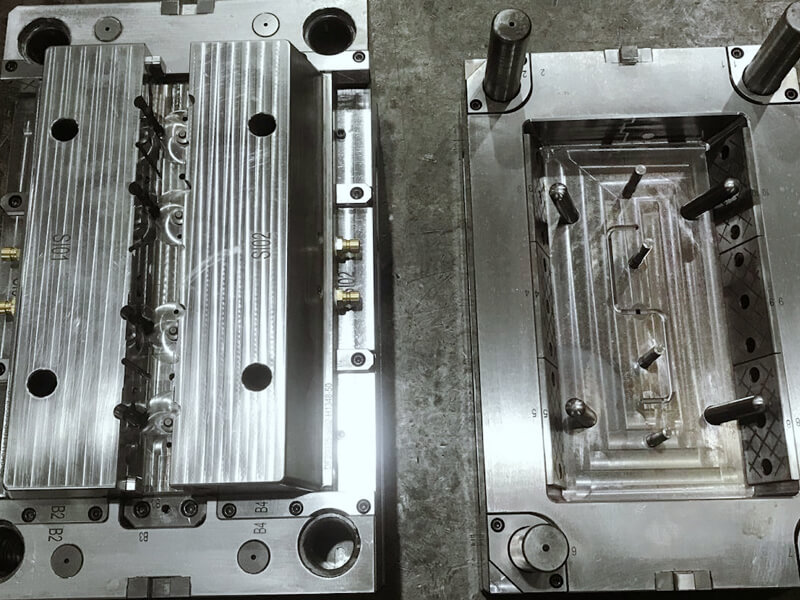

We are mainly engaged in injection mold design, injection mold making, and plastic part molding — including both prototype and high-volume production tools.

Main Industries Served:

- Automotive

- Household

- Cosmetic