About Zibo JinJingChuan

Zibo JinJingChuan New Material Technology Co., Ltd. is a reliable and professional manufacturer of abrasive materials in China. With over two decades of experience, we focus on delivering stable, high-quality abrasives at competitive prices.

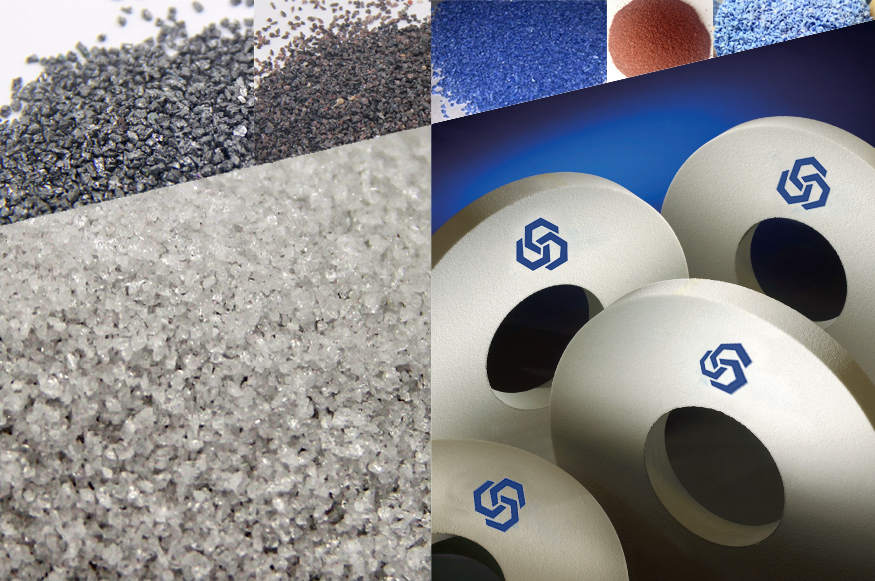

Our expertise spans the production of Black Silicon Carbide, Green Silicon Carbide, Blue Ceramic Abrasive, Brown Fused Alumina, White Fused Alumina, and Pink Fused Alumina — all manufactured to meet international FEPA and JIS standards.

We serve industries ranging from fine grinding and solar energy to advanced ceramics and refractory materials, providing tailored solutions for modern industrial challenges.