About Tankii Alloy

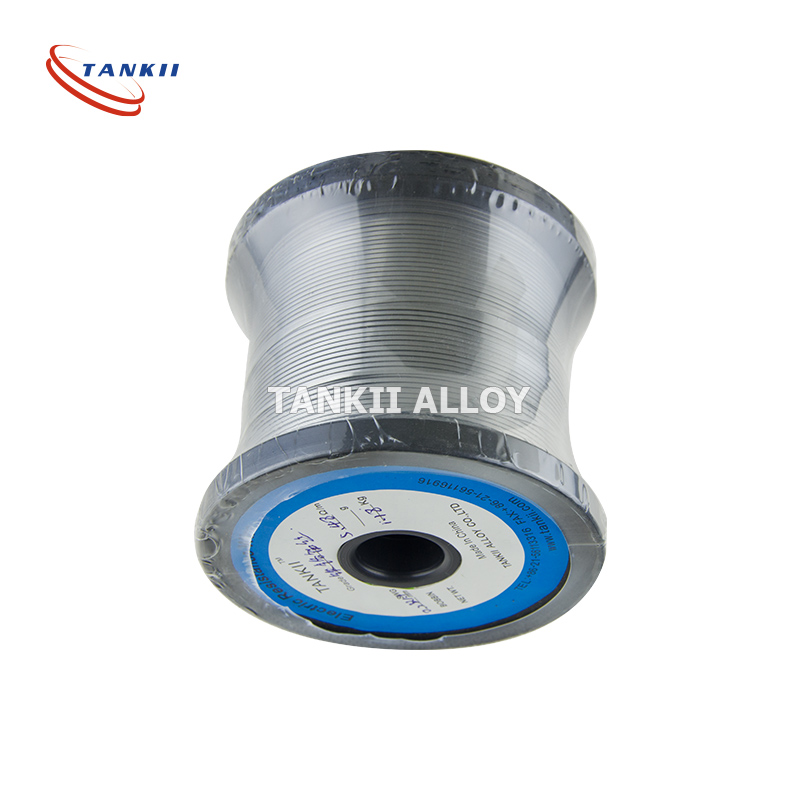

Shanghai Tankii Alloy Material Co., Ltd. is a leading manufacturer and exporter of high-quality resistance alloy materials, serving industries worldwide with precision-engineered solutions.

Following the Spirit of "Good Faith"

Since our founding in 2008, Tankii has been committed to delivering reliable, high-performance alloy materials that meet the rigorous demands of modern industrial applications.

We specialize in resistance alloys used in heating elements, thermocouples, and high-temperature environments across sectors such as energy, aerospace, automotive, and electronics.

Our dedication to quality, innovation, and customer satisfaction has made us a trusted partner for global industry leaders including GE, ABB, Osram, and Saint-Gobain.