About ROTATE DRILLING MOTOR CO., LTD

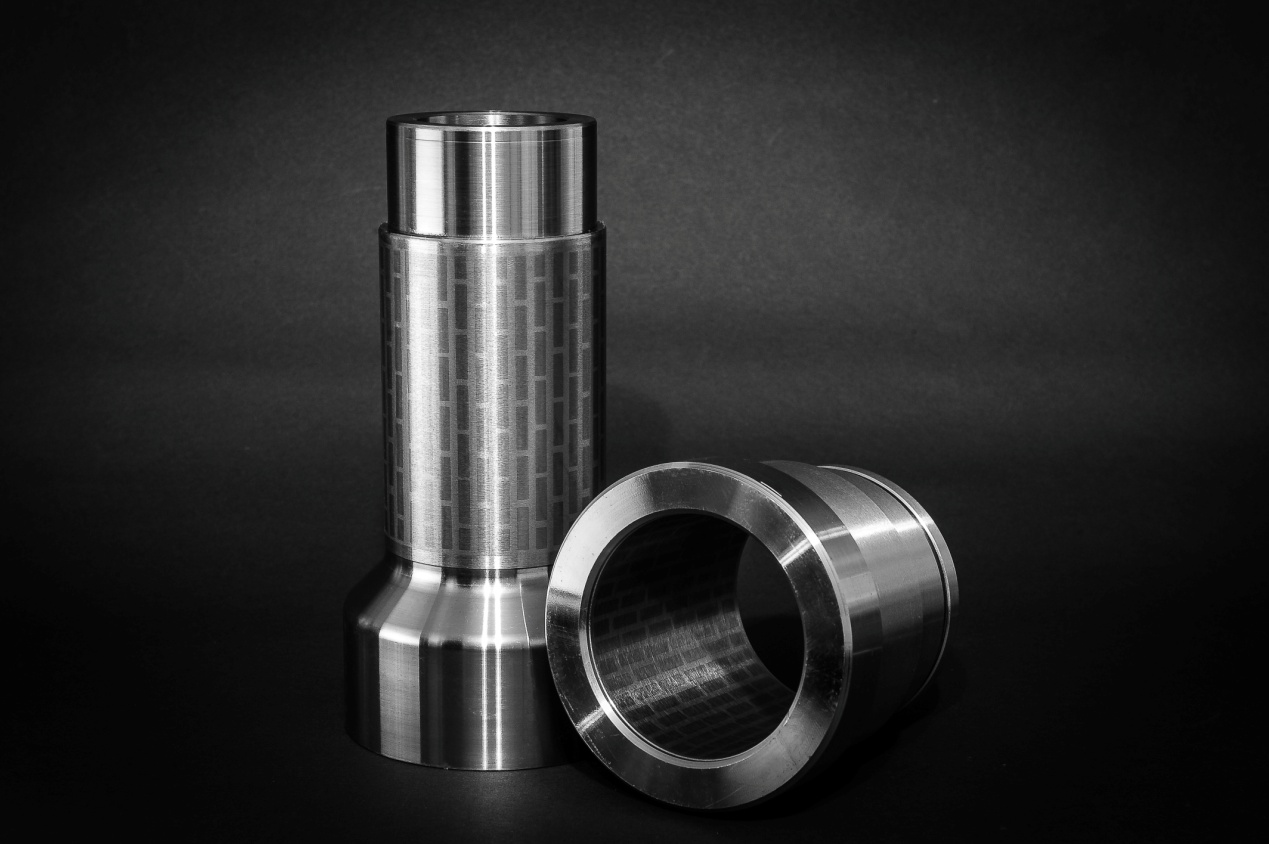

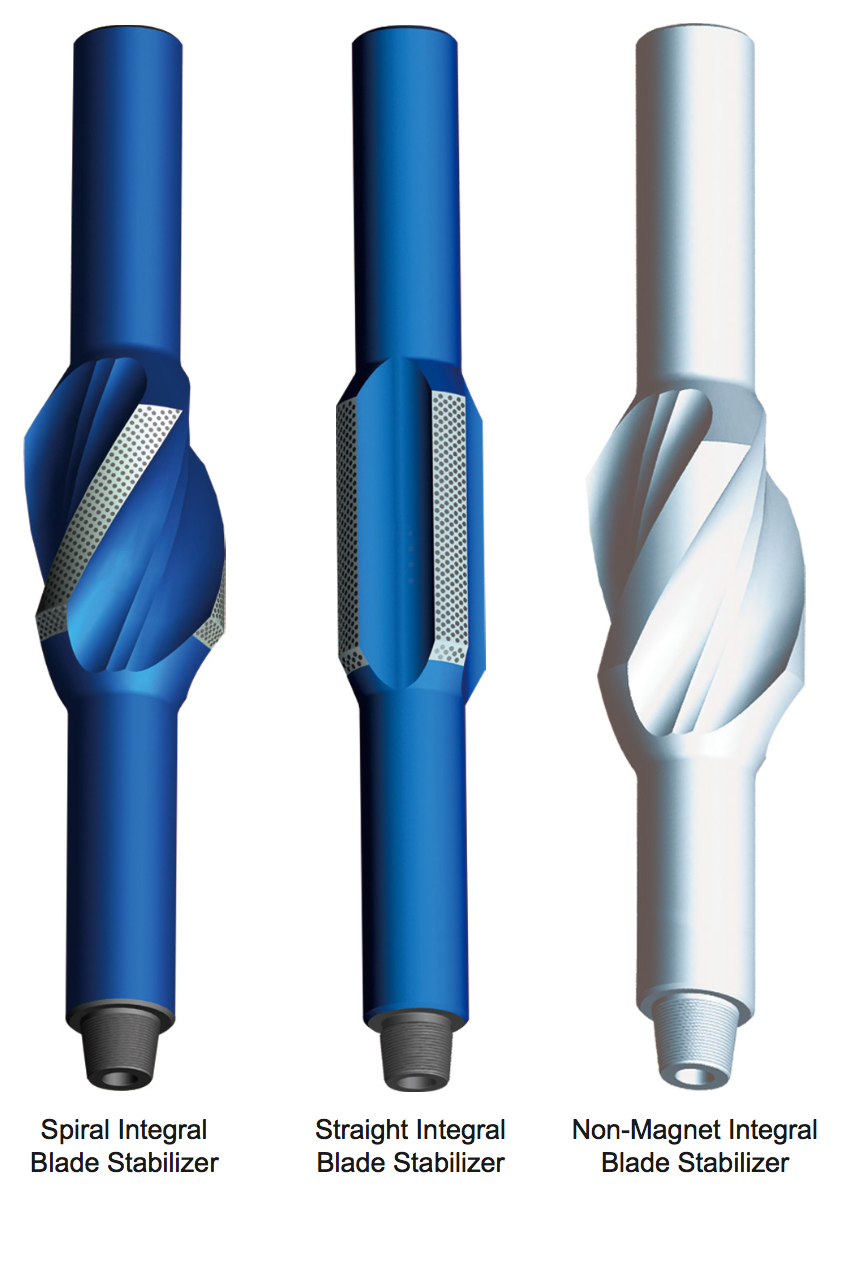

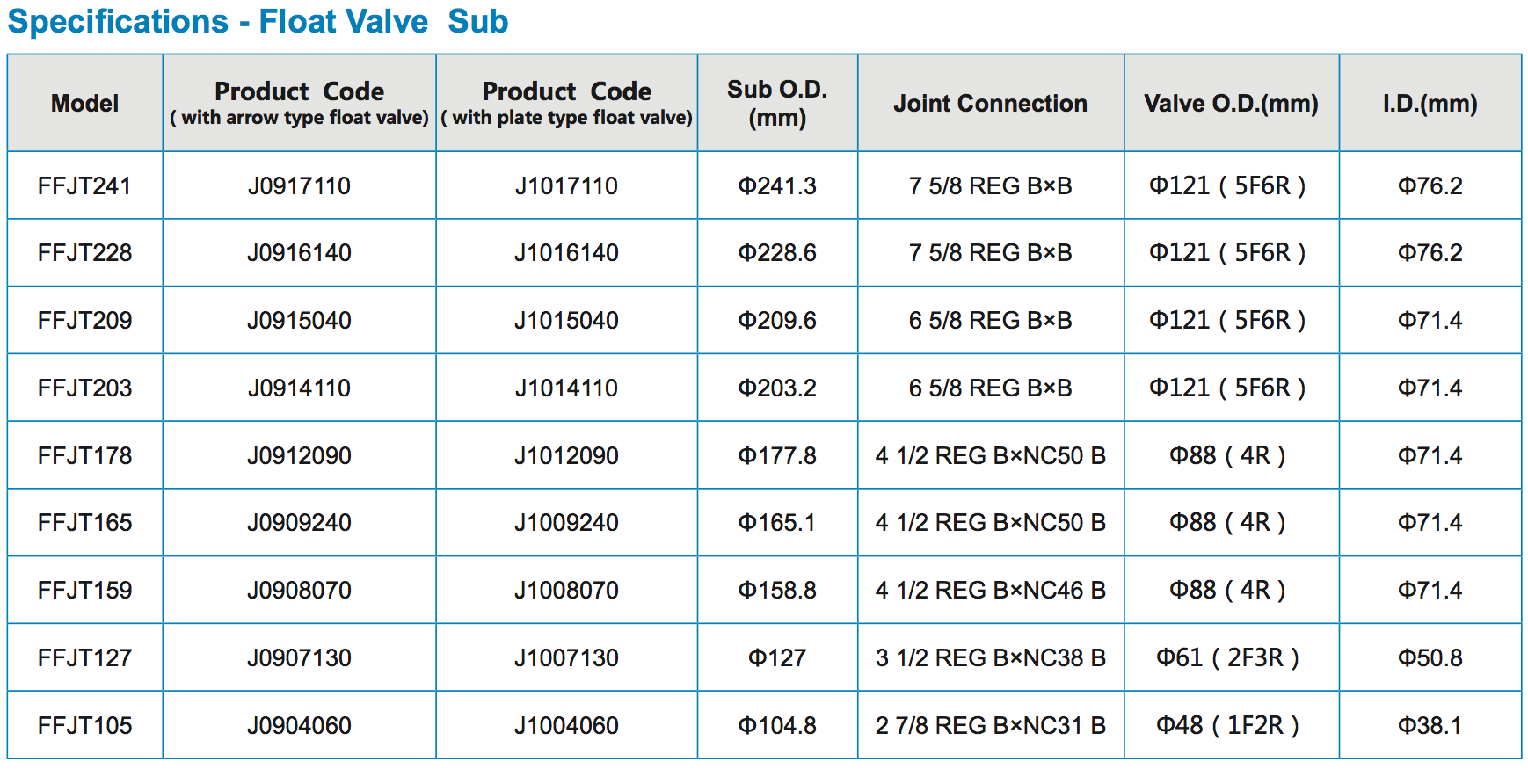

Founded in 2014, ROTATE DRILLING MOTOR CO., LTD specializes in the design and manufacturing of high-performance Tungsten Carbide Radial Bearings, Thrust Stacks, Power Sections, Stabilizers, Centralizers, Rotary Subs, and other critical downhole motor spare parts.

Located in Tianjin — one of China's largest international port cities — our strategic position enables efficient global logistics and rapid delivery to clients across the oil and gas industry.