Precision Metal Stamping & Custom Washer Manufacturing

High-quality, durable metal washers and precision stamping parts engineered for industrial excellence. Trusted by global partners for reliability, consistency, and cost-effective production.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

High-quality, durable metal washers and precision stamping parts engineered for industrial excellence. Trusted by global partners for reliability, consistency, and cost-effective production.

Tech Stamping is a professional manufacturer specializing in precision metal washers and custom stamping components. With years of experience in metal forming and stamping technology, we deliver high-performance parts for automotive, electronics, construction, and industrial machinery sectors.

Our advanced production lines and strict quality control ensure every component meets international standards. From prototype to mass production, we offer scalable solutions tailored to your engineering needs.

Clients Worldwide

Years Experience

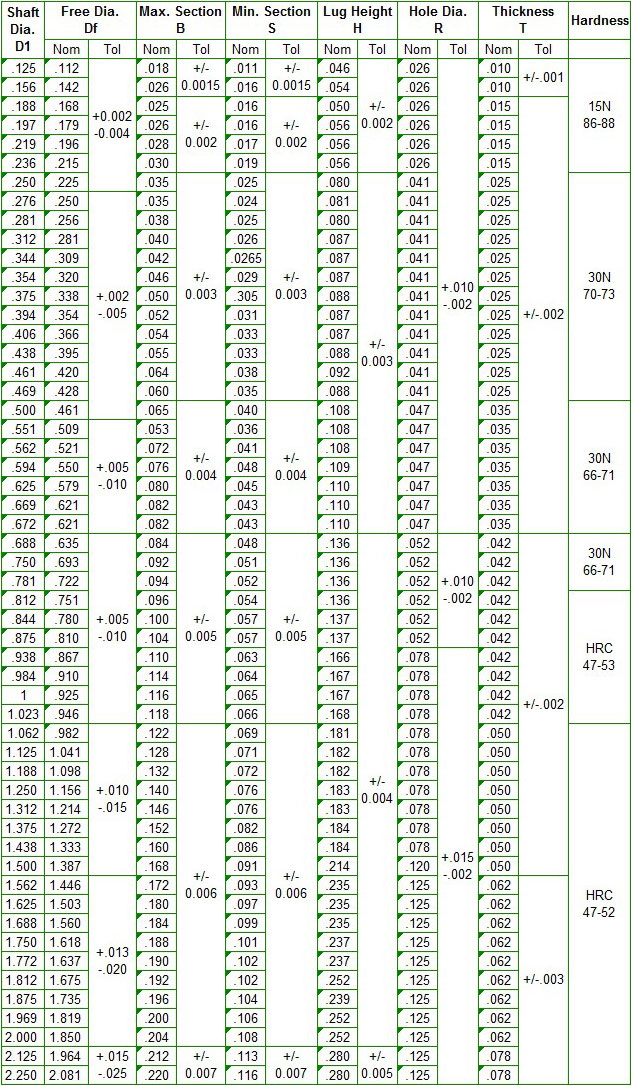

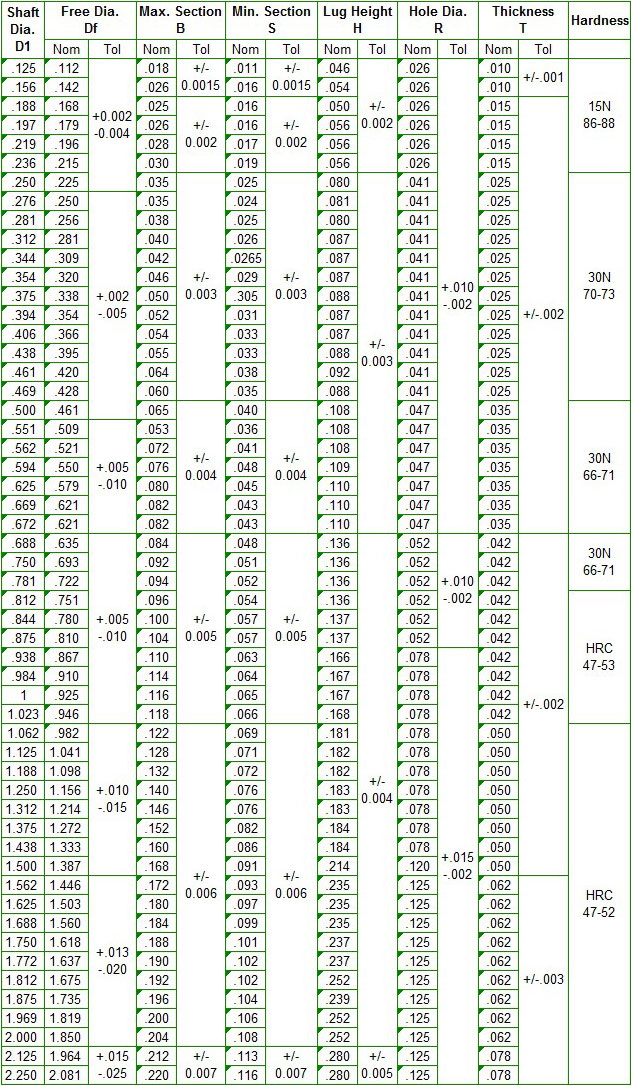

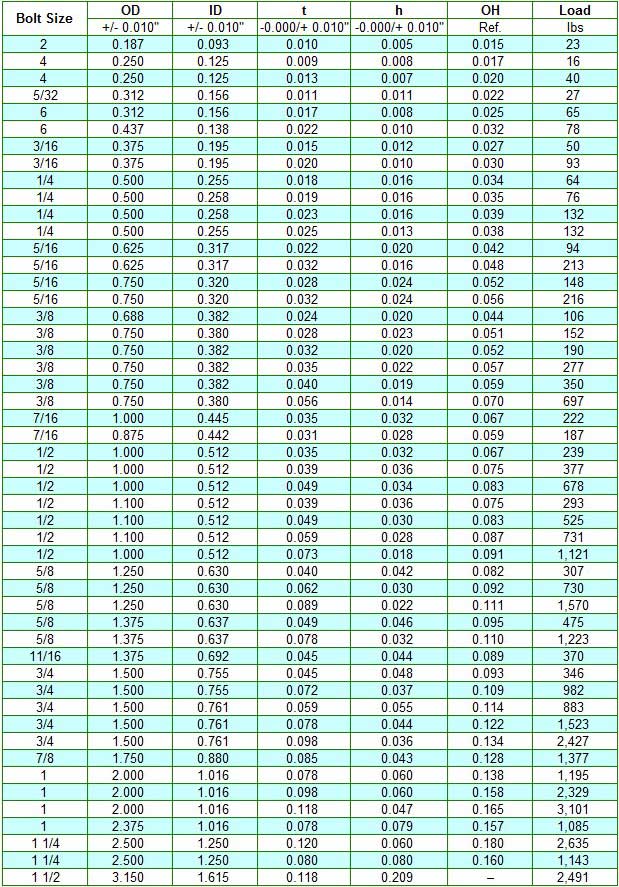

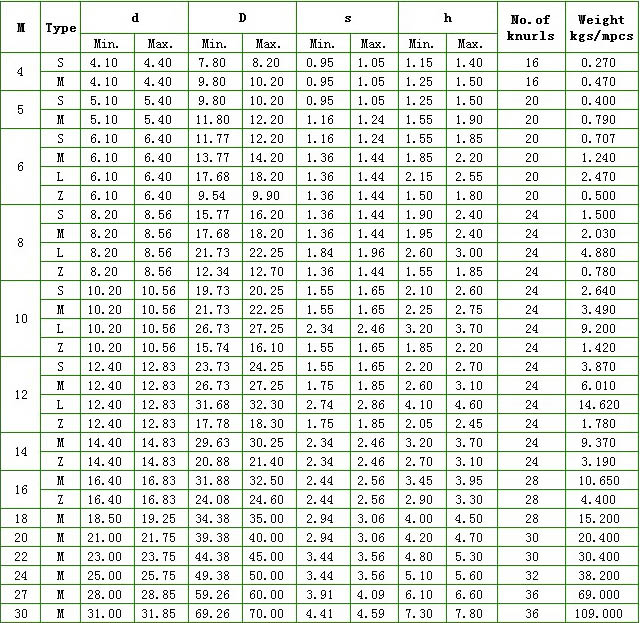

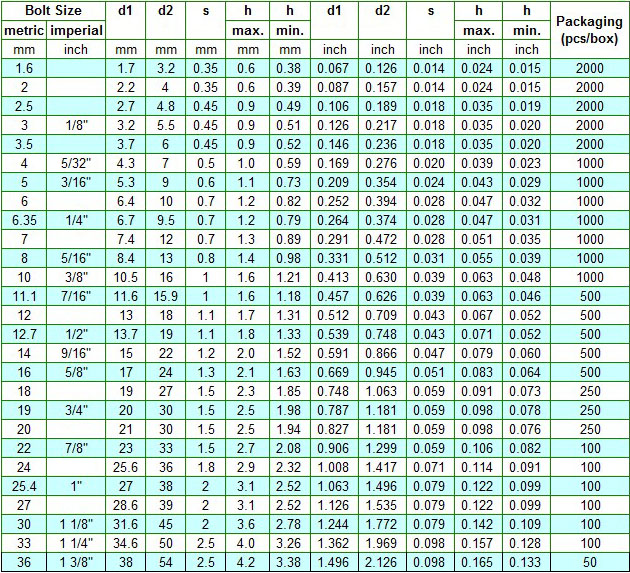

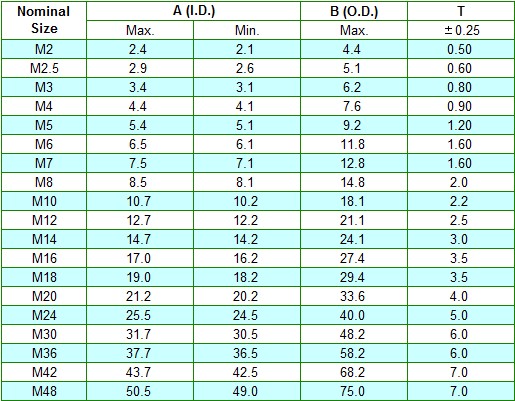

We manufacture a wide range of metal stamping parts and washers with tight tolerances, high durability, and consistent quality. All products are customizable in size, material, and finish.

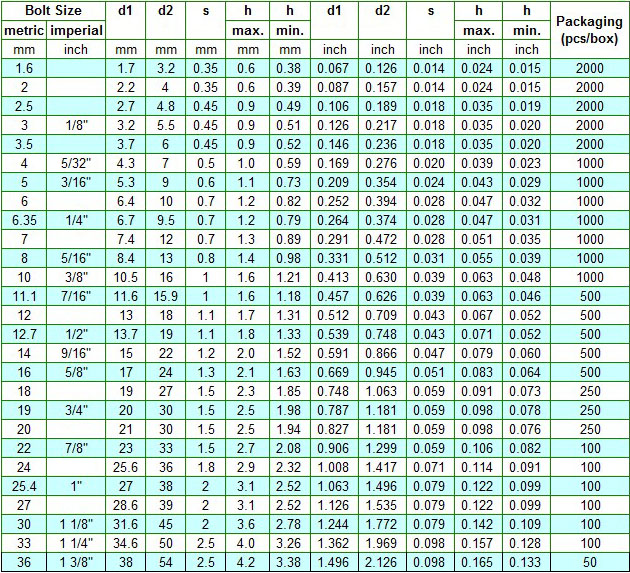

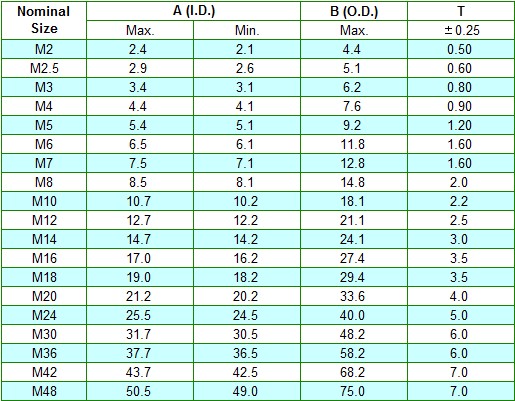

Standard flat washer for general fastening applications. Available in steel, stainless steel, brass.

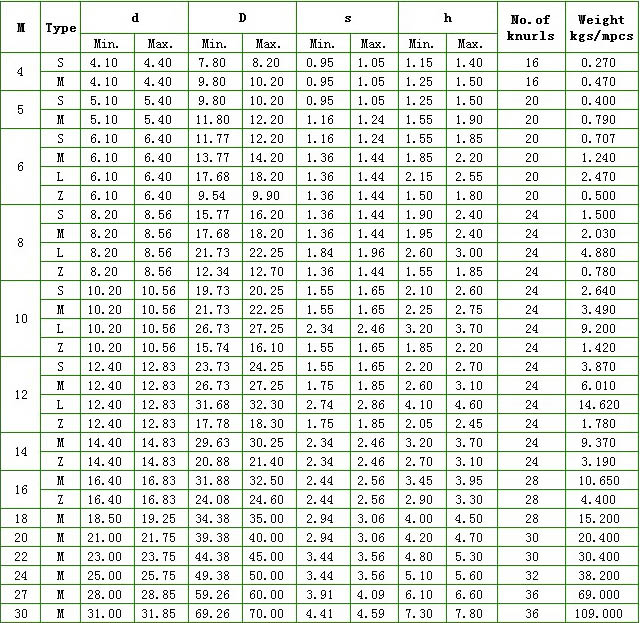

Prevents loosening under vibration. Ideal for automotive and mechanical assemblies.

External/internal tooth design for high-torque applications. Prevents rotation and loosening.

Precision-engineered brackets for industrial and electronic equipment mounting.

Specialized washer with a bent tab for locking in place. Used in electrical and automotive systems.

Provides axial load compensation. Compact alternative to coil springs.

Integrated flange with serrated edge for superior grip and load distribution.

High-conductivity stamped contacts for connectors, relays, and switches.

From design to delivery, we offer end-to-end precision metal stamping services with advanced technology and strict quality assurance.

Up to 200 strokes per minute with progressive and transfer dies for high-volume production efficiency.

ISO-compliant inspection processes including CMM, optical comparators, and material testing.

In-house die design and fabrication for rapid prototyping and low-volume to mass production.

Reliable logistics and export packaging. Serving clients in North America, Europe, and Asia.

Working with carbon steel, stainless steel, brass, copper, aluminum, and specialty alloys.

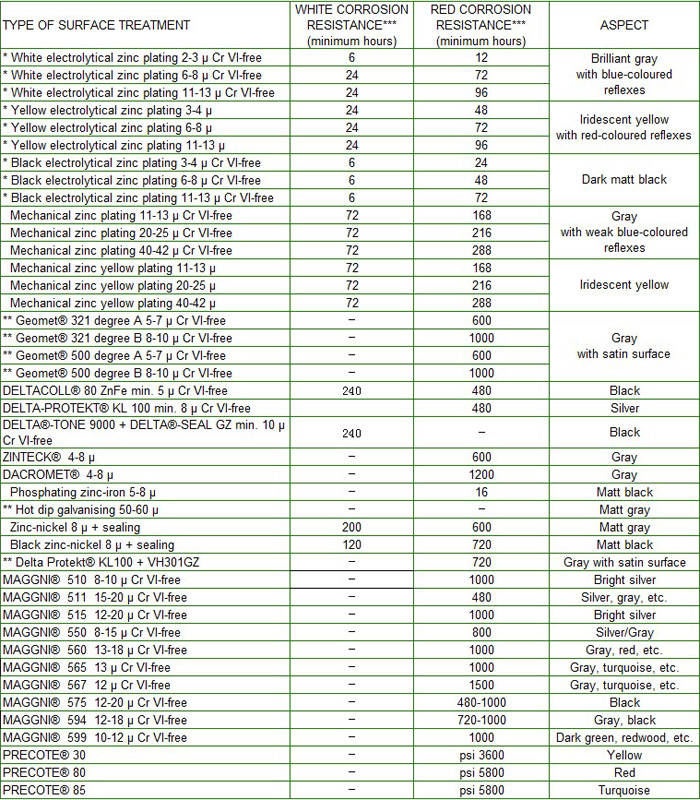

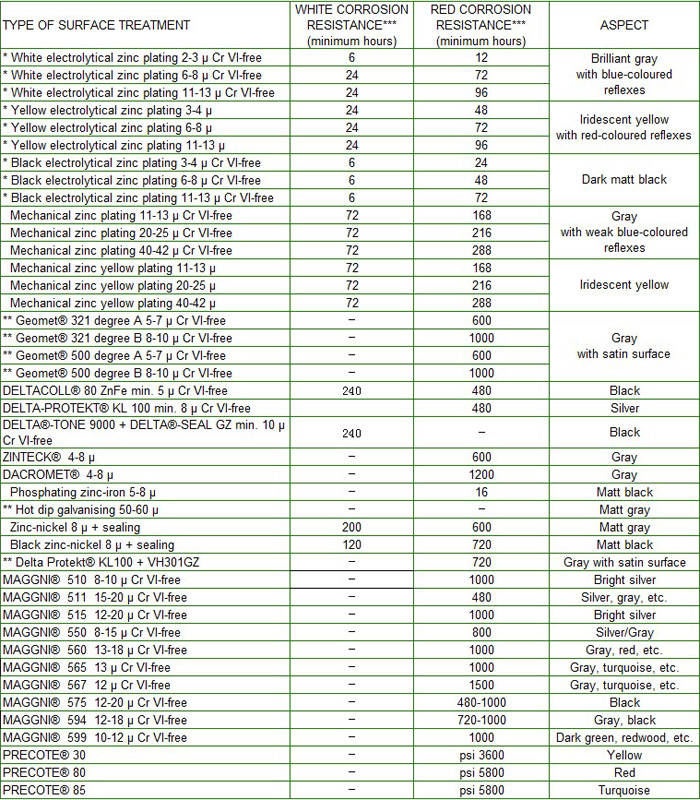

Tapping, threading, heat treatment, plating, and assembly services available.

Global Clients

Years Experience

Parts Annually

Production Lines

We work with carbon steel, stainless steel (304, 316), brass, copper, aluminum, and specialty alloys like beryllium copper and phosphor bronze.

MOQ varies by part complexity and material. For standard washers, MOQ starts at 1,000 pcs. Prototypes and small batches are available.

Yes, we offer free samples for qualified inquiries. Sample lead time is typically 7–10 days.

Our production follows ISO quality standards. We maintain strict process controls and documentation for traceability.

We use incoming material inspection, in-process checks, final inspection with CMM and optical comparators, and batch traceability.

For inquiries, quotes, or technical support, visit our official website to contact the team directly.

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info