Tenlita

Tenlita

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Tenlita

Tenlita

HK Tenlita Technology Limited delivers high-quality CNC machining, 3D printing, sheet metal, injection molding, and die casting solutions from Shenzhen, China. Trusted by global brands like Audi and Midea.

HK Tenlita Technology Limited (Tenlita) is one of the most professional rapid prototype and mold makers in Shenzhen, China. We specialize in delivering precision-engineered components and end-to-end manufacturing solutions for industries ranging from automotive and medical devices to consumer electronics.

Our in-house capabilities include 3D design, rapid prototyping (CNC, 3D printing, vacuum casting), sheet metal fabrication, rapid injection molding, full-scale injection molding, die casting, and product sourcing. With 40 sets of 3-axis CNC machines, 4 sets of 4-axis, 8 sets of 5-axis machines, and 6 industrial 3D printers—including metal 3D printing—we ensure fast turnaround and high precision.

From concept to production, we offer a full suite of precision manufacturing and rapid prototyping services with strict quality control and competitive pricing.

High-precision CNC milling and turning with tolerances up to ±0.3% mm. We operate 40+ CNC machines including 3-axis, 4-axis, and 5-axis systems for complex geometries.

Precision turning operations for cylindrical parts. Ideal for shafts, bushings, and rotational components with tight tolerances and smooth surface finishes.

Industrial-grade 3D printing including metal 3D printing. Fast prototyping and low-volume production with high accuracy and material versatility.

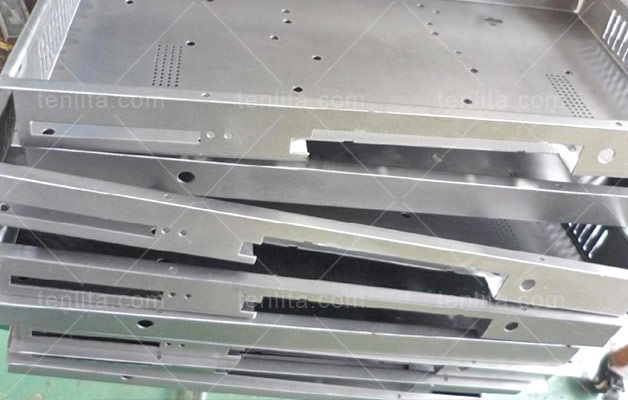

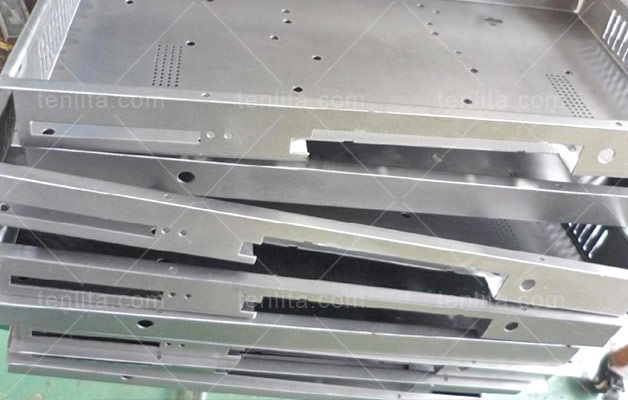

Applied to consumer products, medical devices, enclosures, and industrial components. Includes laser cutting, bending, welding, and finishing.

Ideal for low-volume production of rubber or plastic parts. Fast turnaround and cost-effective for small batches and functional prototypes.

Accelerated mold development and low-volume injection molding. Saves time and cost for product validation and market testing.

High-pressure die casting for aluminum and zinc alloys. Suitable for high-strength, complex metal parts in automotive and industrial applications.

High-quality polyurethane casting under vacuum for small batch production. Excellent surface finish and material properties mimicking final products.

End-to-end product sourcing and supply chain management. From design to delivery, we handle manufacturing, quality control, and logistics.

Precision-machined parts for automotive applications with tight tolerances and high durability. Used by Audi suppliers.

Sterile, corrosion-resistant enclosures for diagnostic and surgical equipment. Compliant with medical standards.

SLA and metal 3D printing for functional prototypes and end-use parts with fine detail and smooth surfaces.

High-speed lathe machining for shafts, connectors, and threaded parts with excellent concentricity.

Durable, lightweight housings for industrial and consumer electronics with complex geometries.

Low-volume production of rubber-like or rigid plastic parts with properties close to injection molded.

Fast mold fabrication for testing and low-volume production. Cost-effective alternative to steel molds.

Ideal for soft-touch components, gaskets, and seals. Fast turnaround and low tooling cost.

"Helmets are received. They look very good. Thank you for your effort. Hope to work with you again."

"Car parts have been tested, it seems now all look very good. Customers are very satisfied with this. Thanks."

"I have checked the goods and they look good but no description was included, hope all are in the box."

We work with aluminum, steel, stainless steel, brass, copper, titanium, and various engineering plastics like ABS, PC, POM, and nylon.

Yes, we have industrial metal 3D printers capable of printing stainless steel, titanium, and aluminum parts with high precision.

Standard lead time is 5–7 days for prototypes and 10–15 days for production runs, depending on complexity and volume.

Yes, we are ISO9001 certified with a full QC process including 2D and 3D inspection equipment.

Absolutely. We specialize in rapid prototyping and low-volume manufacturing using CNC, 3D printing, silicone molding, and rapid injection molding.

For inquiries, quotes, or project discussions, reach out to us via email. We respond promptly to all messages.

Email:

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info